Capital of the Nord-Pas de Calais region, Lille is France’s fourth largest metropolitan area. The city has a population of 226,800, although the urban area extends over the Belgian border and is estimated at around 1.75 million. Its economic fortunes have been transformed thanks to the Single European Market and, more specifically, its location at the centre of important commercial routes linking Britain, France and Belgium with the rest of mainland Europe.

The VAL system’s name was originally derived from the local names Villeneuve d’Ascq à Lille, although as the format became adopted elsewhere, generically it now represents Véhicule Automatique Léger (automatic light vehicle). The two lines now have an operational length of 45km (28 miles), the largest fully automatic network in the world.

The project

The first moves towards a new, integrated rapid transit system for Lille were taken in 1971. For the first time anywhere in the world it was decided to opt for an entirely automated, driverless subway. French company Matra Transport International (with growing Siemens involvement from 1995, re-named Siemens Transportation Systems in November 2001) was selected to develop and build it.

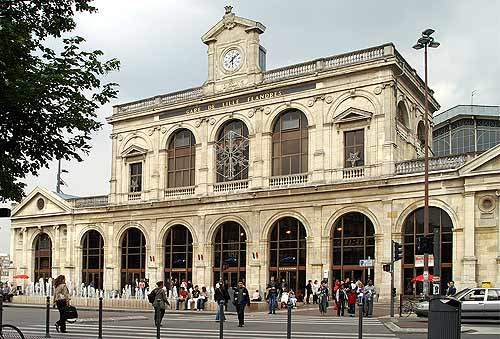

The prototype appeared in 1973 and, after three years of exhaustive testing, the CUDL (the Lille local authority) was convinced of its flexibility, economic benefits and greater suitability to its environment over existing systems. Construction began in 1978 and the service opened in April 1983, initially from République to 4 Cantons via the main heavy rail station, Lille Flandres.

Full opening of the 13.5km (8.4 mile) Line 1 was in the following year. Critics believed it might be little more than a novelty but upon opening it was an immediate success.

Work on a second line, west from Lille Flandres to Saint Philbert, began in April 1989. For the opening of the TGV Nord and completion of the new Lille Europe station in 1994, VAL Line 2 was extended the 500m north from Lille Flandres.

Momentum for further developments was maintained with expansion from Lille Europe north-eastwards to Fort de Mons. Development continued at a steady pace and 1999 saw the start of commercial services on the fourth phase of Line 2, from Fort de Mons to Tourcoing Centre. Following northern extensions to the area’s main hospital at Dron, close to the Belgian border, at 32km (19.9 miles) the line is the world’s longest single automated route.

Infrastructure

The VAL concept is of rubber-tyred vehicles using a segregated fully automated guideway. Running in tunnel or on elevated alignments, the permanent way is made up of the running-tracks, guide bars (which also deliver the 750v dc current) and the automatic control devices. Although long-term staffing levels are inherently low, the substantial VAL infrastructure is a relatively expensive system to create.

Line 1 station platforms were built 26m long, whereas Line 2 station platforms were 52m at the outset to accommodate for two VAL vehicles. A high proportion of stations have connections with other public transport, including bus routes, Lille’s two-route tram service and SNCF, with many large adjoining car parks. By 2003 VAL had 62 stations on 45km of operational lines, of which 14km are in tunnel.

The three maintenance and repair sidings comprise a four-road workshop area at the end of Line 1 and Line 2 and a storage depot at Grand, but at the south-western extremity of the network, a further stabling area was created in 2000 on completion of the northerly Line 2 extension. Passenger safety is ensured at stations as each is segregated from the running tracks by a series of transparent sliding doors, opening only when trains have stopped.

Rolling stock

VAL trains were developed by Matra as an integral part of the system; the earlier VAL206 being represented on both lines.

The new generation VAL 208 units used on Line 2 are considerably more powerful than their predecessors as each wheelset is powered, a total of eight for each two-car train set, and a much more suitable mode of propulsion over the greater distances.

Seating configurations in VAL 208 vehicles are designed to be flexible to allow them to be adapted according to the density of traffic expected. This gives an individual vehicle capacity varying from 140 to 245 per twin-car unit.

With improvements in braking, propulsion, the guidance mechanism and body structure, the weight of the new vehicles is 14t compared with 15.5t for their predecessors. The high level of traction of rubber tyres on the concrete tracks offers rapid acceleration and braking, with easy handling of the system’s steep inclines.

Signalling and communications

Operators monitor the entire system from the central control room and are in full charge, starting from switching on the power to the tracks. They choose the operation programme to be used for that day, defining frequency of service. The system then ‘wakes’ the trains, and assigns them various tasks according to the operation programme.

In fully automatic mode, control room staff receive remote signals from each train on computer screens every two seconds, building up a picture of the overall status of the system. When a train stops in a station, information is fed back from lineside equipment to the train to ensure that opening and closing of both train and platform doors is done safely. Control room operators can intervene in an emergency.

Station dwell times are short, and although not the operating norm, headways can be as little as 60 seconds. While the system normally operates 05.13am to 12.30am, the flexibility of the signalling is illustrated by the Lille festival in September when the system has continual operation for 44 hours.

The future

Lille’s VAL system has run at a profit since 1989 and, despite vandalism and concerns over personal safety, ridership figures remain healthy. Further expansion of both lines is under consideration. A proposed Line 2 extension, from C.H. Dron to Mouscron, would take VAL into Belgium.

In December 2006, Lille system operator Transpole selected a consortium of Alstom and Safra to update VAL, an €11m contract that includes modernisation of 38 metro trainsets comprising rolling stock designed and manufactured by Alstom in the 1980s. The contract includes aesthetical evolution of old seats and floors, and technical mechanical and electronic updates.

Alstom and Safra each have a 50% stake in the modernisationproject. Alstom is responsible for project management and coordination, renovation of the running gear and door mechanisms, overhaul of the traction motors and testing. Safra handles the interior and exterior refitting of the metro coaches.

Module 1 of the modernisation covers the body of the trains. For the first three trains, Safra conducted non-destructive control of the bogies. This encompassed crack research, painting of the exterior body and installation of new seats and flooring. It also included modification of LV and HV cabling and connectors, restoration of coupler head and door mechanisms and changing of the liaison body.

Alstom’s work in module 1 includes the overhaul of all DC traction, control and qualification for each train and design of the renovation and kitting out of the pneumatic doors.

Module 2, being handled by Alstom alone, includes non-destructive control of the structure for the first 12 bogies. It also includes installation of new LV and HV cables, overhaul of the axle gear reduction units, axle restoration of the guiding wheel and control and mechanical adjustment.

Modernisation efforts started in January 2007 with the delivery of the first trainsets in the third quarter of 2007. Other deliveries are set for August 2009.

Following Lille’s successful experience, other French locations adoptong the VAL concept include Toulouse (1993) and Rennes (2002), with airport applications at Paris Orly (1992) and a system linking termini at Paris Charles De Gaulle opening in 2007. Other applications in Turin, Chicago, Taipei and Uijeongbu (South Korea) have cemented the success of this distinctive and reliable light rail system.