The Municipality of Budapest and the State Government ordered the construction of a mass transit underground system in early 1998. The project was vigorously examined, and deemed to be the best answer to Budapest’s increasing transport problems.

Planning in earnest of Metro 4 began in 1995 when a feasibility study was commissioned, and this resulted in contracts for construction being let in 1998. However, a lack of funding support from the government led to cancellation of the contracts soon after and it wasn’t until 2003 that finance for the project was put in place.

Construction of Metro 4 began in 2004, with the aim of completing the first phase of the project by 2007–09. It was later rescheduled to 2012.

The project

Planning in earnest began in 1995 when a feasibility study was commissioned. However, a lack of funding support from the government led to the cancellation of the contracts soon after. It wasn’t until 2003 that finance for the project was put in place.

The initial ten station 7.3km underground section between Kelenfold railway station and Keleti railway station will be able to provide South Buda and the downtown area with adequate long-term service in conjunction with the priorities of urban development. The second and third sections are scheduled to be completed by 2014.

The line’s carrying capacity depends upon the composition of the train and the utility of the safety equipment. On completion the line will have a maximum speed of 70–80km/h between stations with an average speed of 30km/h.

Some journey times will halve compared to express bus routes. Significantly Metro 4 will also include an additional crossing of the River Danube, which flows through the centre of Budapest, and the new crossing is expected to reduce traffic flows on other bridges by up to 60%. The project is budgeted to take between three and five years to complete, which could see the first trains in service by 2012.

Infrastructure

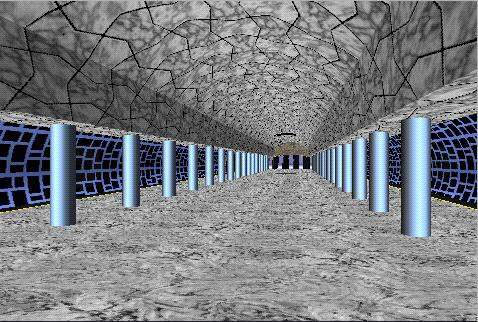

In order to construct the tunnels under Budapest, Metro 4 will employ Tunnel Boring Machines (TBM) to bore out the tunnels. The walls of the tunnels will be built using the Shield Tunnelling method using reinforced concrete segments.

The two running lines of Metro 4 (one for each direction) will run in separate tunnels for the majority of the route, apart from strategically located crossings to allow the operation of trains even in the event of a train failure in one of the tunnels.

Stations will be built at depths between 12.9m and 30m below ground, which is allowing Metro 4 to build the stations from ground level down as box structures using concrete slabs, although some sections will require shotcrete technology to complete the building works.

In total the first phase of the project will see 10 stations built: Kelenfold pu (interchange with main line railway services), Tetenvi ut, Bocskai ut, Moricz Zsigmond korter, Szent Gellert ter, Fovam ter, Kalvin ter, Rakoczi ter, Nepszinhaz utca and Keleti pu.

Another major structure connected to Metro 4 is a new 84,000m2 maintenance depot near Kelenfold station. The new depot will be used for storing vehicles, as well as maintenance of rolling stock and infrastructure. A connection to the MAV (Hungarian National Railway Network) will also be built to allow easy movement of Metro 4 rolling stock when necessary.

As part of its contract to equip the system with automatic control, Siemens Transportation Systems will also fit out the maintenance depot at Kelenfold station with driverless control. The company has also been contracted to install the power supply and electrification on Metro 4.

Rolling stock

DBR Metro already has a detailed specification of what it is looking for in terms of new trains. In order to maximise cost efficiency, the trains are to be designed for low maintenance requirements, with a minimum lifecycle of 30–35 years using the latest railway technology and systems.

In contrast to earlier trains on the Budapest Metro, the new trains will have gangways between the cars, allowing passengers the flexibility and additional safety of passage between the vehicles of each four-car train.

A lightweight structure will be used for the car bodies, while underfloor they will employ three-phase asynchronous motors and energy-saving braking systems with regenerative capabilities.

Passenger comfort, safety and aesthetics are also important points to consider, as Metro 4 is being designed to entice road users to opt for public transport instead of private cars.

Signalling

Siemens Transportation Systems was awarded the contract to equip Metro 4 with control and safety equipment in October 2006. The contract includes the provision of driverless control equipment, which will make the route the first to be fully automatic in Hungary when it opens in 2012.

During the start-up phase of operation each train will travel with an attendant who will monitor the Automatic Train Control system. Drivers will have the ability to override the system and take control during testing and start-up.

A central Traffic Control Centre is being built as part of the project to manage the operation of the new 7.3km line, as well as trains entering or leaving the maintenance sites.

The future

The large investment required for the project is justified by considerable advantages, one of the most important of which is that travellers will spend 14 million fewer hours each year in transit.

The significant time savings in mass transit and road traffic as well as the savings made in terms of environmental protection and fewer road accidents, will, as shown by the cost-benefit analysis, result in an 8.3% internal rate of return for the project.

Metro 4 will ease traffic congestion in the centre of Budapest, with up to 11,000 cars owners stating that they will use the new line when it opens in preference to driving into the city centre. There is also scope for future expansion of Metro 4 to reach further out of the city centre.

In addition, DBR Metro is expecting other businesses to be keen to invest in the area surrounding Metro 4 as it brings a much-improved transport system to the city.