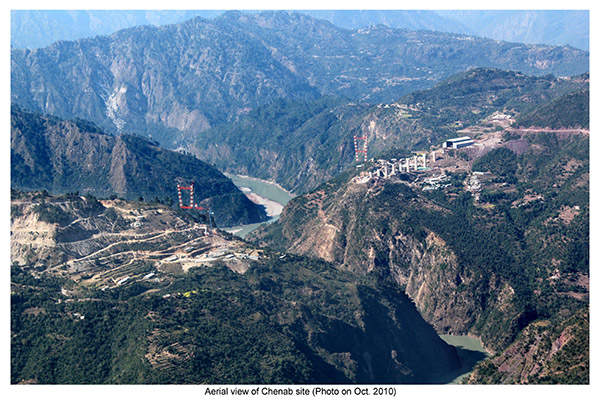

Chenab Bridge is located between Bakkal and Kauri in the Reasi district of Jammu and Kashmir (J&K), India. Built at a height of 359m, the 1,315m-long structure is the tallest rail bridge in the world.

The Rs14.86bn ($181m) bridge is a part of the Jammu-Udhampur-Srinagar-Baramulla Rail Line (JUSBRL) project being undertaken by the Ministry of Indian Railways. The bridge will include a 14m-wide dual carriageway and a 1.2m-wide central verge.

The construction of the bridge was completed in August 2022, with the track laying work on the bridge completed in March 2023.

Scheduled to enter service in 2024, the Chenab Bridge will have a lifespan of 120 years. It will contribute to local economic development and better transportation accessibility in the region.

Background of the Chenab rail bridge

Travelling in and around the mountainous terrain of J&K has been a great difficulty for local residents. An urgent need to provide improved transportation facilities was recognised by the Government of India. Construction of a national railway project that will connect J&K with the rest of India was therefore proposed.

The JUSBRL project was launched in 2003 as part of this proposal. The 345km section between the Jammu and Baramulla regions will enhance mobility within J&K and across India. The railway line will traverse along Jammu-Udhampur-Katra-Quazigund-Baramulla. Construction of the Jammu-Udhampur section was completed and opened in April 2005.

Around 161km of the 272km Udhampur-Baramulla section has already been completed, with work progressing on the remaining 111km Katra-Banihal section, which is expected to be completed in 2024.

The project includes the construction of several bridges and tunnels along the route, including the Chenab Bridge. It spans across the deep Chenab River to provide access to the Kashmir Valley from Udhampur.

The JUSBRL project was suspended in 2008 due to construction challenges. The alignment of the entire project was reviewed to propose solutions for the challenges faced. The review work was submitted to the Indian Railway Board and approved in 2009. The design of the railway bridge, however, was approved in July 2012.

Chenab Bridge design details

Chenab Bridge forms a large steel arch, the first of its kind in India. The country has no codes or design guidance for such structures. Based on experiences drawn from similar projects worldwide, the design practices for the bridge were followed.

BS: 5400 was used as the basic guideline for the design and construction of the bridge. The deep Chenab River valley under the bridge is prone to high wind pressure risking the stability of the bridge.

Norway-based Force Technology Laboratory conducted several wind tunnel tests to understand the effects of wind speed, static force coefficients and gust buffeting. The bridge is designed to resist wind speeds of up to 260km/h. The seismic nature of the project zone was also considered during its design.

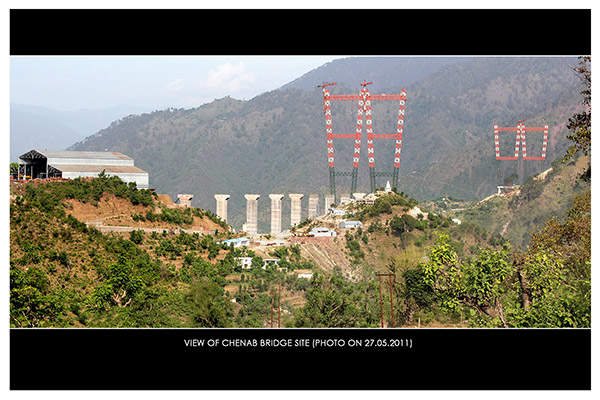

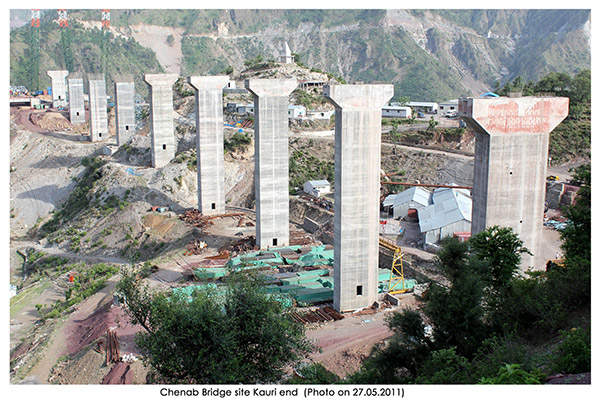

The bridge includes 17 spans, as well as the 469m main arch span across the Chenab River, and viaducts on either side. The main span of the bridge includes two 36m-long approach spans. It is built as a two-ribbed arch with steel trusses made of concrete-filled sealed steel boxes. The structure is supported by two 130m-long, 100m-high pylons on either end through cables.

Steel was chosen to construct the bridge as it was more economical and will be able to resist temperatures of -20°C and wind speeds exceeding 200km/h. The J&K region witnesses frequent terrorist attacks. To enhance safety and security, the bridge is made of 63mm-thick special blast-proof steel. The concrete pillars of the bridge are designed to withstand explosions. It is expected that the structure will be able to withstand earthquakes of magnitude eight on Richter Scale and up to 40kg of TNT blasts.

A ring of aerial security will be provided to safeguard the bridge. An online monitoring and warning system will be installed on the bridge to protect the passengers and train in critical conditions. Footpaths and cycle trails will be provided adjacent to it. The bridge will be painted with a special corrosion-resistant paint, which lasts for 15 years.

Chenab Bridge construction details

The bridge was constructed in one of the most complicated and isolated terrains. One of the biggest challenges involved was the construction of the bridge without obstructing the flow of the river. Approach roads measuring five kilometres in length were constructed to reach the foundations of the bridge.

The deck of the bridge is located on a transition curve with changing radius. Construction was therefore carried out in stages following the gradual change in the alignment. This is the first time a bridge was constructed incrementally on a transition curve.

Cable cranes and derricks were used to construct the bridge. The cable cranes used for the project were one of the largest in the world.

Construction of the bridge required 25,000t of steel, 4,000t of reinforced steel, 46,000m³ of concrete and eight million cubic metres of excavation. The construction of the bridge was discontinued in 2008 due to alignment and safety issues. It was resumed in 2010, with estimated completion in 2015, which was subsequently pushed to 2019.

The construction of the iconic steel arch of the bridge was completed in April 2021, with the construction of the overarch deck completed in August 2022.

Contractors involved in the construction of the Chenab Bridge

Amberg Engineering was appointed to carry out review work of the alignments. Konkan Railway Corporation is executing the project. The design and construction of the bridge were awarded to a joint venture comprising Afcons Infrastructure, Ultra Construction & Engineering Company of South Korea and VSL India in 2004.

Finland-based WSP Group and Germany-based Leonhardt Andra and Partners are the consultants for the project. VCE Consult ZT-GmbH designed the pylons of the bridge. Jochum Andreas Seiltransporte installed the cables for the pylon. AkzoNobel was awarded the painting services contract for the bridge.

AECOM was awarded a contract to provide technical guidance and monitoring services for design and construction works. The scope included engineering services, proof-checking the project drawings and design, ground engineering, planning and consulting.

Essar Steel India was the steel provider while Swiss company Mageba provided spherical stopper bearings for the construction of the bridge.