Montréal Pneumatic Material 2010 (MPM-10) metro cars are being manufactured by a joint venture between Bombardier Transportation and Alstom for Montreal Metro, the rapid transit system for Montreal in Quebec, Canada. The MPM-10 metro cars will replace the ageing MR-63 vehicles, which have been operating on the Montreal Metro since 1966.

The new cars are being manufactured under a $1.2bn contract awarded to a Bombardier-Alstom consortium by operator Société de transport de Montréal (STM) in October 2010. The contract includes the delivery of 468 MPM-10 vehicles. The manufacturing cost of each car unit is estimated at around $2.64m.

The MPM-10 train sets are expected to be put into operation from 2014 on the Orange line of the Montreal Metro. After the first delivery, a nine-car train will be added to the fleet every month.

The new MPM-10 cars are expected to significantly increase passenger comfort with their high performance.

Development of the new MPM-10 metro cars

Proposals for the replacement of the MR-63 rolling stock were discussed in 2006. The manufacturing contract was first awarded to Bombardier Transportation without organising a bidding process, a decision which was challenged by Alstom. Consequently, a bidding process was organised in which the joint venture of Bombardier and Alstom won the bid.

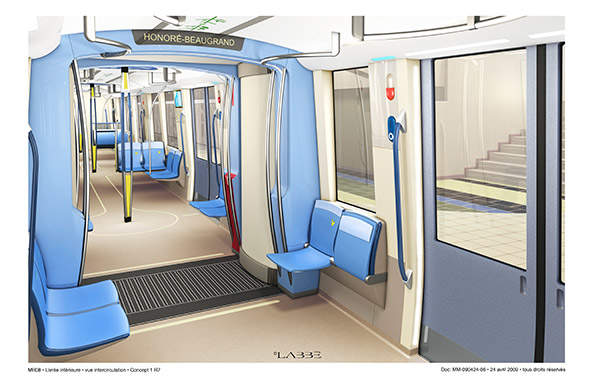

The Bombardier-Alstom consortium has employed quality expertise in cognitive ergonomics and industrial design fields to develop the prototype of the MPM-10 vehicle. The passenger compartment of the rail car was designed by Labbé Designers et associés during the initial definition and evolution process.

STM is supporting the design and development process by employing full-scale models that can accurately reproduce the simulated system by integrating the majority of the components. These models help in evaluating a number of aspects, including compatibility with technical specifications, three-dimensional layout, human-machine interface, a selection of materials and disassembly, and replacement of components.

The overall design of the concept and layout was completed by summer 2011. A first-scale passenger compartment model was designed with wood and cardboard, and tested on target groups, which include transit users, passengers with functional limitations and STM employees.

Based on the feedback from target groups, STM was able to understand the design specifications of the cars, such as the seating and standing area, lighting, doors and windows, integration of information systems, positioning of emergency break handles and support poles. The feedback served as a template for developing and manufacturing the new cars.

MPM-10 metro cars design

A number of improvements have been made to the MPM-10 rolling stock compared to previous MR-63 cars. The design of the MPM-10 train sets includes nine open concept cars, in which passengers can move freely from one end to other. The boa type car will ensure smooth entry, exit and internal circulation of the passengers. The inter-circulation module with a minimum opening of 1,300mm eliminates the risk of falling between the cars.

Related project

Union Station, Toronto, Canada

Union Station is a major multimodal railway transportation hub in Toronto, Canada. It is one of the busiest stations in the country and serves more than 250,000 passengers a day.

Three double sliding doors will be fixed on each side of the car. These electric motor doors are equipped with obstruction sensors and audio-visual door closing signalling. The cars of the new vehicle will be 27% wider than the current ones. The design also includes partitions for physically challenged people.

The total length of the nine-car set is 152.43m and width of each car is 2.51m. The width and height of each car door is 1.65m and 1.95m respectively.

The outer shell of the rail car body will be made of aluminium sheets and the wall panels will be made of stainless steel structure. The roof of the rail car will be made of streamlined aluminium.

Propulsion and performance of MPM-10 metro cars

The train set will use energy efficient propulsion with recuperative braking system, which minimises the usage of mechanical brakes. The bogies of the new trains will run on pneumatic tire systems similar to the ones being used on the present network. The pneumatic systems offer smooth ride and passenger comfort. Air suspension systems will also be installed to ensure a comfortable ride for passengers.

The famous STM-manufactured wooden break shoes will be included in the bogies of the new cars adapting the MP05 bogie system. This system is used to prevent wearing of steel safety wheels and also to ensure quieter breaking.

The maximum slope of the vehicle is fixed at 6.5%, and it vehicle will run on a traction power of 750Vcc with a maximum speed of 72.4kmph.

Features of the new Montreal Metro rolling stock

The rail car will be provided with an automatically adjustable ventilation system, which works depending on passenger load and temperature. The maximum output of the ventilation system will be 13,000m3/h and it offers more comfort for passengers than the existing MR-63 cars.

The car’s seating arrangement is based on universal accessibility requirements. The design has 22 fixed seats, two fold-up seats and two lumbar-supported wheel chair spaces. The cars in the middle will have a seating capacity of 32, of which four are fold-up seats.

Four multifunctional screens and two screens displaying passenger information of next station and service delays will be installed in each car. Additionally three passenger interphones (five in-end cars), four surveillance cameras and an automated announcement system will be fixed in each car.

Each car of the train set will feature indirect ceiling lights, which produce ambient lighting. The lights will be operated using fixed florescent tubes. A vertical band of LED lighting system will be installed in the door frames to indicate door closure. In addition, LED accent lights will be installed throughout the passenger compartment.