Cleensonic/Ultratecno manufactures specially designed cleaning equipment and solutions for train engines and rail components.

With its ultrasonic technology, Cleensonic’s solutions are suitable for rail and other transport industries where powerful sonic cleaning action and large tanks are required. With decades of experience in offering ultrasonic cleaning equipment to transport industries, the company has pioneered many new ultrasonic cleaning technology applications that can be incorporated into different industrial processes.

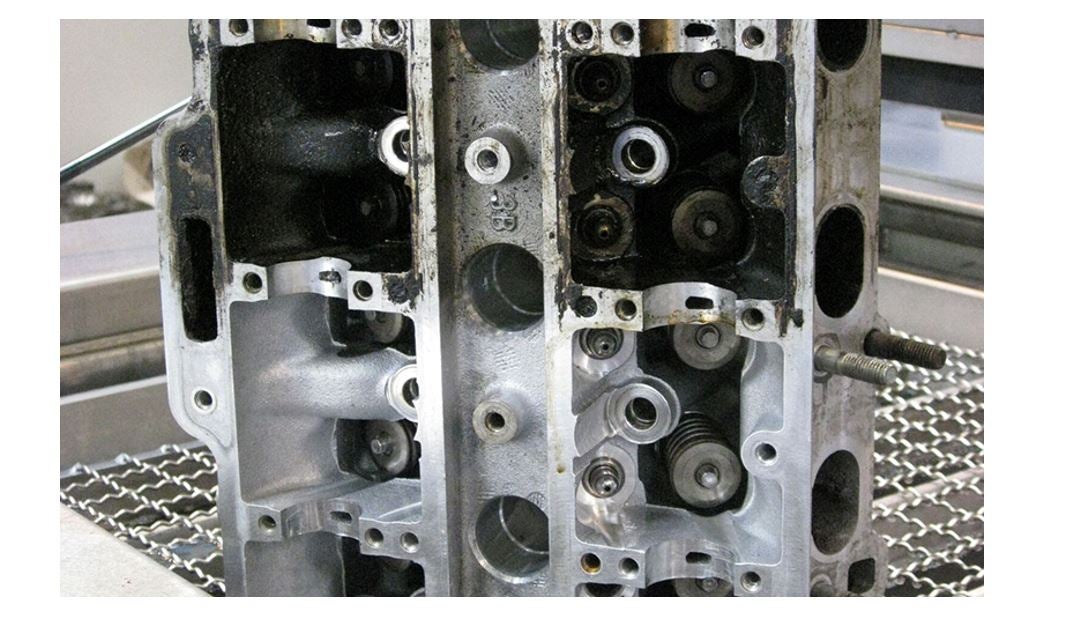

Ultrasonic cleaning can be used on a variety of rail components such as gearboxes, hot boxes, axle boxes, engine blocks, engine heads, wheel bearings and wagon interiors.

Ultrasonic cleaning systems for rail maintenance

Cleensonic’s equipment is optimised for cleaning all types of train components and is capable of handling loads of up to 1,800kg.

Ultrasonic cleaning is particularly effective for cleaning small interior cracks and crevices, where vision and access are both limited, and can also deliver a high-performance clean to both the interior and exterior of railway vehicles.

Cleensonic’s ultrasonic cleaning machines are an environmentally friendly, fast, and thorough way to remove machine oil, dirt, and other contaminants from railway equipment, tools, and components.

Benefits of ultrasonic cleaning equipment in the rail industry

Ultrasonic technology is an extremely useful tool for producing high-quality results while also minimising energy consumption and increasing the effectiveness of production processes across many industries.

Ultrasonic cleaning does not just use water to agitate a fluid but a combination of water and an appropriate solvent or detergent to enhance the effect, which allows for a deeper and more thorough clean. This process typically lasts for 15 to 30 minutes but can exceed 60 to 90 minutes, depending on the application.

There are five main advantages to ultrasonic cleaning, which include:

- Consistent results

- Minimal contact with harmful chemicals to make cleaning jobs safer

- Quicker cleaning, resulting in increased productivity

- The adjustable and non-contact scrubbing action is ideal for cleaning more delicate equipment

- Can be used to clean hard-to-reach areas

Automated cleaning systems for rail components

To reduce labour costs and provide the best prices for customers, some projects require the assistance of automation.

Cleensonic specialises in manufacturing automated equipmentd, meaning it can operate continuously, with short stoppages only needed to replace any cleaning liquids. This means that Cleensonic’s equipment has the potential to clean up to 110,000 aluminium tubes per day, making it both efficient and reliable.

Automatic and robotised cleaning helps to optimise efficiency and maintain a uniform standard of operations. The company’s turnkey projects provide customers with high-quality parts that can meet all customer technical specifications.

Ultrasonic cleaners

With such a large range of products available, selecting the correct ultrasonic cleaner can be challenging for first-time buyers.

To decide which size cleaning tank is best, users should first consider the size of the parts that require cleaning. Cleensonic recommends that its customers take into consideration not only the size of the components, but also the quantity, shape, and cleaning schedule.

Heat is also required for ultrasonic cleaning as ultrasonic energy works most effectively with water at temperatures between 40°C and 70°C. Hot water also helps to dissolve certain types of soil and dirt, resulting in a more thorough cleaning. The cost of heating the volume of water inside the tank and maintaining this temperature must therefore be considered.

Benchtop ultrasonic cleaning machines for rail components

A leading developer in the precision ultrasonic cleaning industry, CREST manufactures benchtop ultrasonic cleaning units. They have been used in both aqueous and solvent systems, which serve a wide variety of cleaning applications.

That same high-performance technology is incorporated into Cleensonic’s Powersonic tabletop cleaners, which provide the strength and quality of an industrial cleaner at a tabletop price.

With capacities ranging from 2L to 26L, these benchtop units are ideal for cleaning a range of small parts and are used across many sectors, including the rail, transport, medical, and jewellery cleaning industries.

Industrial rail tabletop cleaning systems

The CS SERIES industrial tabletop units are suitable for use in rail, engineering, and automotive workshops.

Featuring a heated ultrasonic tank, with a durable stainless-steel tank and body, these tabletop solutions are designed to clean small-to-medium-sized metal components and mechanical assemblies.

Single-tank industrial rail cleaning equipment

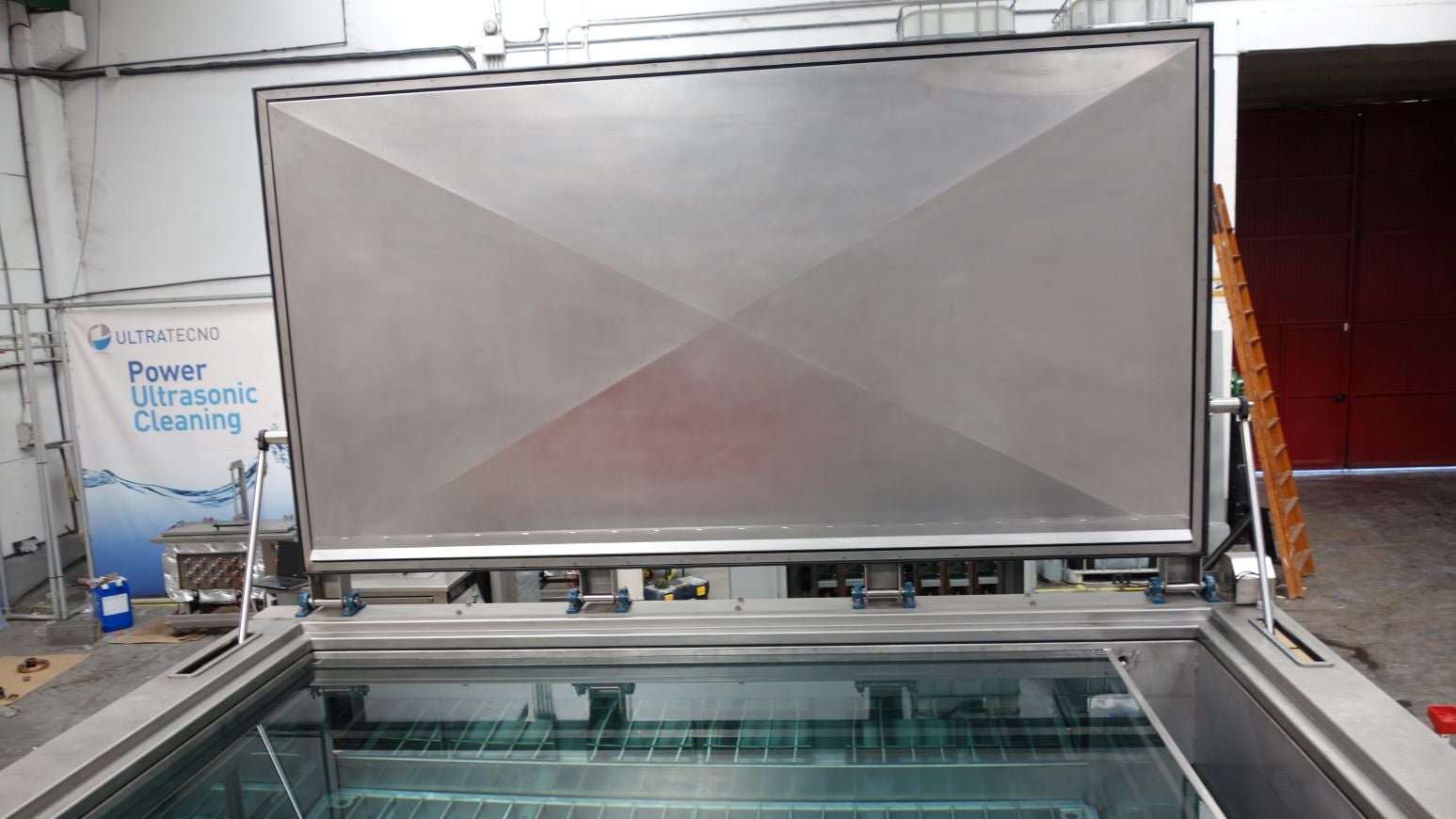

UltraTecno’s ACM/ICM series of cleaning solutions have been engineered to provide cost-efficient ultrasonic cleaning solutions in a single tank configuration.

Fitted with the latest technology, UltraTecno’s cleaning systems are recognised worldwide for their superior build quality. Its ultrasonic and supersonic cleaners offer impressive cleaning results while also reducing consumption and labour costs, without using solvents.

Cleensonic’s ACM range includes a hydraulic or pneumatic lifting platform, capable of supporting up to 2t, to automatically stir and move parts during the cleaning process.

About Cleensonic

With more than 20 years of experience in providing cleaning technologies, Cleensonic recognises the importance of cleaning equipment that can be used across a variety of organisations and facilities.

Using ultrasonic technology, the company’s cleaners can remove contaminants from nearly any hard surface that can be safely immersed in the cleaning solution.