- 360º camera scan of rolling stock

- AI-assisted diagnosis

- Automation for all vision inspections

- Configurable modules for all rolling stocks

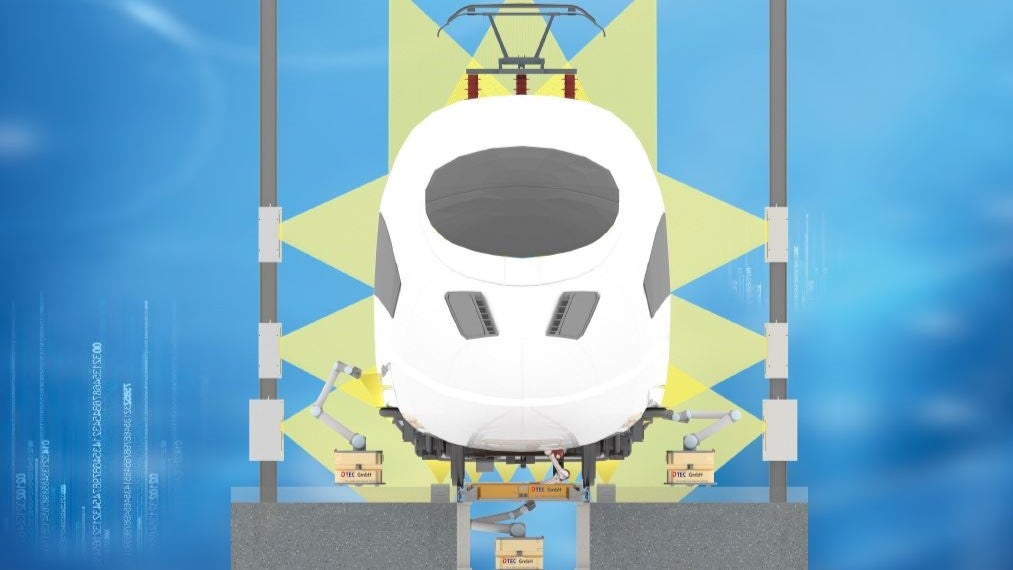

Wayside vision/vision gate (VG)

Vision Gate (VG), also known as Camera Gate, is a part of DTEC’s Vision Inspection Solution, which provides fully automated visual inspections of a vehicle. The Vision Gate is configurable with multiple functional modules, which automatically starts image capture when a train passes. Based on inspection requirement, Vision Gate is applicable for vision inspections of a train’s top, side, and bottom areas. Optionally, the DTEC AI algorithm can be applied during failure recognition and diagnoses. Anomalies are predefined to improve inspection efficiency.

Functions

- Non-stop visual condition monitoring

- Automatic 360º panoramic vehicle image

- Image based measurement

- AI-assisted analysis and diagnoses

- Trend prediction

Specifications

- Wide inspection speed range (5km/h~60km/h)

- Up to 80% vision inspection task coverage

- 2D and 3D combined reconstruction and visualisation

- Various AI-based anomalies recognition

- Individual configurable image accuracy in different areas

- Longtime operation in outdoor areas

Your benefits

- Avoid onsite heavy duty

- Fully automatic processes

- Visualised digital inspection

- Uniform rating standard

Flexible vision/vision robot (VR)

AVR is an autonomous mobile platform carrying a flexible robot arm with a camera module. It moves self-guided for automatic vision inspections at bogie side and the underfloor area.

TVR is an autonomous mobile platform carrying a flexible robot arm with a camera module. TVR can be applied in the parking yard for automatic vision inspections of the underfloor area. The wheel system of TVR is specially designed for moving between tracks without, any modification of infrastructure.

Functions

- Automatic underfloor panoramic imaging

- Component concentrated image capture

- Image based measurements

- AI-assisted analysis and diagnoses

- Trend prediction

Specifications

- Robot speed: Max 1m/s

- High 2D and 3D image accuracy

- Automatic self positioning

- Automatic component concentrated image capture

- Various anomaly recognition

- High accuracy measurements

Your benefits

- Avoid onsite heavy duty

- Full automatic inspection processes

- Visualised digital inspection

- Uniform rating standard