MTM Power has been a reliable and experienced partner to the railway industry for over 30 years. In recent years, the company has become one of Europe’s largest manufacturers of power supplies for railway applications.

The company’s devices are specifically designed to operate under the most challenging of conditions and comply with all relevant railway operational standards. Resistant to mechanical stresses, such as shock, vibration, or environmental influences, including condensation, humidity and conductive dusts, the converters are developed in accordance with EN 50155, EN 45545-2 and EN 50121-3-2 standards. They are suitable for use in demanding railway applications and are used by companies across the world.

Thermoselective vacuum encapsulation for railway applications

MTM Power has developed patented thermoselective vacuum encapsulation technology for power supplies and DC/DC converters that comply with all relevant standards. The thermal coupling of the components to the surface, using the encapsulation material of the housing or base plate, prevents the development of hotspots and economically guarantees a broadly homogenous temperature distribution in the power supply unit.

The high degree of efficiency and use of suitable materials for the housing means that the company’s products are guaranteed to exceed the normative specifications for the touchable surfaces. This technology offers the highest level of IP protection for the circuit board.

MTM Power has unparalleled expertise in this technology, ensuring the highest level of protection for sensitive electronic power supplies and exceptional resilience against mechanical, thermal, and other environmental effects when compared to similar encapsulated power supplies.

DC/DC converters for railways

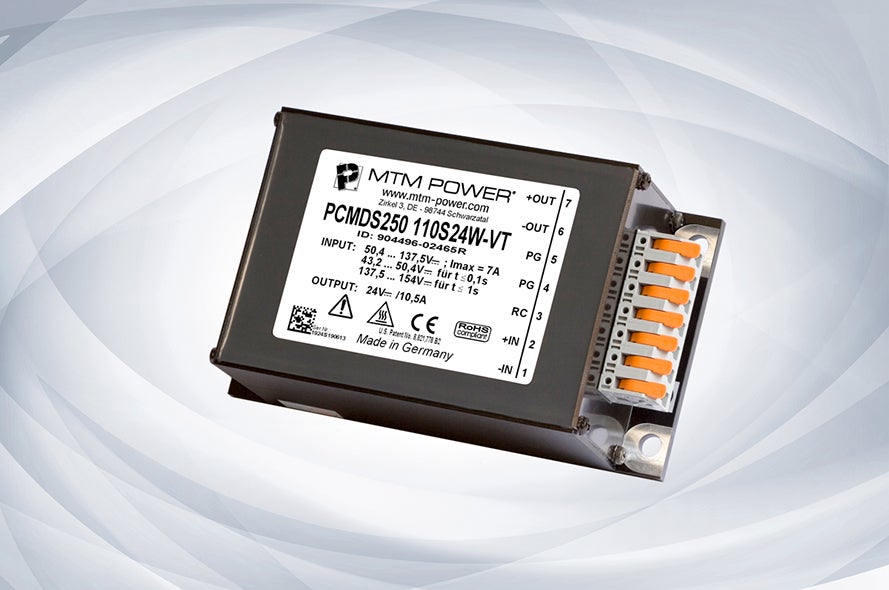

The MTM Power PCMDS series is designed for railway applications, offering high resistance to mechanical stress, shock, vibration, and environmental influences like condensation, humidity, and conductive dust. These converters comply with EN 50 155, and EN 45 545-2 standards and are suitable for mounting in train roofs, under floors, driver’s cabs, engine compartments, and wagons.

They cover battery voltages from 24V to 110V (EN 50 155) and provide 30W to 400W of output power, with galvanically isolated voltages from 5V to 48V. Spring clamps ensure vibration-resistant, maintenance-free operation while connector integration simplifies wiring and replacement. 30W and 150W models are also available as 19-inch plug-in units.

Certified to EN 50 155, EN 50 121-3-2, EN 61 373, Cat 1,and Class B specifications, these converters meet the EN 45 545-2 fire protection standards. They operate using a push-pull topology, ensuring constant efficiency over wide input voltages. Pulse-width modulation (PWM) and IU characteristics enable stable power for critical loads, such as motors and halogen lamps.

A thermoselective vacuum encapsulation (US Patent 8,821,778 B2) ensures optimal heat dissipation and durability. Additional features include reverse polarity protection, active input current limiting, and free convection cooling. For optimal performance, mounting on a heat-dissipating surface is recommended.

Railway AC/DC power supplies for IP67 applications

The PM-IP67A200 series from MTM Power is designed for IP67 applications, offering a robust, reliable power supply for control, sensor, and actuation systems. Unlike conventional power supplies requiring control cabinets, these units enable direct plug-and-play use with 7in/8in connectors and thermo-selective vacuum encapsulation, ensuring protection against moisture, dust, and mechanical stress.

With a wide input range (90-264 VAC/100-300 VDC), these 24V single and dual output power supplies feature 3.3kVAC galvanic isolation for safe and stable operation. The integrated power boost function temporarily increases output by 50%, making it ideal for motors and capacitive loads.

Certified to UL 60 950-1, UL 508, UL 1310, and NEC Class 2 specifications, the PM-IP67A200 series meets EMC standards and the Low Voltage Directive. Its rugged SMD design, automated final testing, short-circuit protection, and -25°C to 75°C operating range ensure durability and efficiency for demanding, on-machine applications.

Power supply systems for the railway industry

MTM Power’s range of products for railway applications include:

- AC/DC power supplies up to 150W

- DC/DC converters in a power range between 15W and 650W, with a power boost up to 1.000W

- Value add solutions with a high grade of flexibility up to 2.000W, based on existing products

- Custom designed power supplies for individual tasks in the system power supply

Some key features of the company’s power supplies include :

- Designed to meet requirements according to EN 50155 standards

- Extended temperature range of -4°C to +85°C

- Convection cooled without the need for air force cooling

- Rugged design in accordance with EN 61373 Cat. 1, Class B (shock/vibration) requirements

- Fire protection that meets EN 45545-2 standards

- Extended life time

About MTM Power

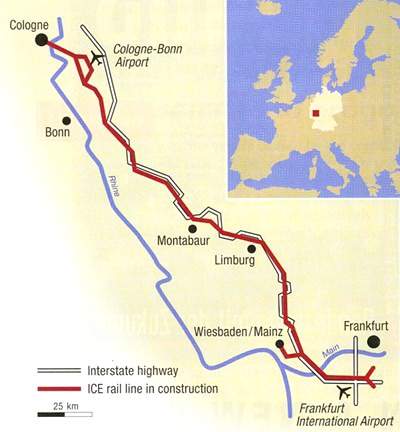

MTM Power’s products are used for many different applications, such as train control and traction technology, door controls, air conditioning systems, train lighting, braking systems, electronic displays, signalling, windscreen wiper engines, and passenger counting and information systems. The company’s solutions are also used in European train control systems.

The company’s success is based on the quality of its innovative products, as well as the flexibility and reliability of its core business. Expert technological and industrial knowledge is combined with the highest quality standards.

More information about MTM Power’s range of products can be found under the Products & Services tab.