Paulstra, part of Hutchinson Group (€2.6 billion, 24,000 people, 100 industrial sites), is world leader in the design, manufacture and supply of antivibration solutions dedicated to the railway industry. Hutchinson Paulstra proposes a range of complete gangways for trains.

Hutchinson Paulstra is present in Europe, America and Asia, supporting the major rolling stock manufacturers, equipment manufacturers and operators. In addition to already designed and qualified gangways, Hutchinson Paulstra also engineers customised solutions in accordance with its customers’ needs. All these gangways are then tested and qualified on a dedicated gangway test bench in Hutchinson Paulstra’s test center before entering service.

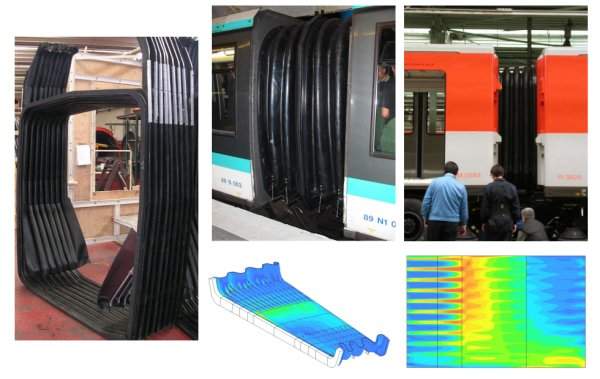

INTER-VEHICLE METRO GANGWAYS

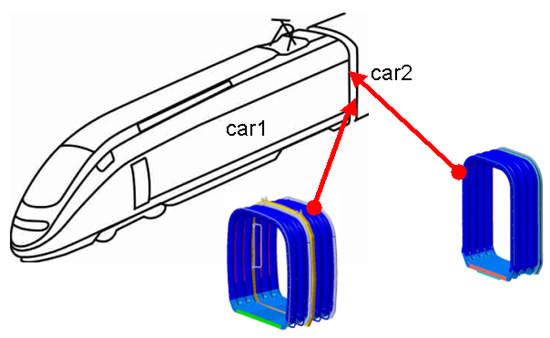

Hutchinson, utilizing the expertise of Paulstra and LJF, has developed its range of inter-vehicle gangways for metro applications using advanced Finite Element Analysis (FEA).

The interconnecting gangway is a self-supporting design, ensuring a safe passenger path between two consecutive cars. The gangway doesn’t require any additional vertical support, thus avoiding any interference with the vehicle’s coupling bar and therefore eliminating wear and maintenance.

The fire and smoke classified rubbers are reinforced with metal plates for the floors and embedded fabrics for the bellows. As no metal plates are sliding, the risk of shear injury is eradicated. The gangway is designed to become a passenger carrying area during peak hours. Grab handles are fitted for passenger comfort.

The floor of the gangway is at the same level as the vehicle floor, allowing wheelchair and pushchair access. Being completely enclosed and airtight, passengers are protected from external conditions. The gangway doesn’t generate noise and vibration. The rubber offers a very high isolation barrier between two consecutive cars and provides a significant noise reduction from the outside.

A fast disconnecting system, proposed as an option, allows to separate promptly the two cars’ connection. In most of the configurations, the separation of coupling bar, pneumatic hoses and electrical harnesses is not required.

The undulated surface with associated reinforcement protects the gangway against acts of vandalism and graffiti.

The rubber used in the design of the gangway, avoiding conventional displacement of metallic parts and wear due to gangway motion, contributes to reduce significantly LCC (Life Cycle Cost).

Due to its design, Hutchinson Paulstra gangway requires very limited maintenance operations.

TRAMWAY AND LIGHT TRAIN GANGWAYS

Hutchinson Paulstra light gangways properly answer to all types of specifications in terms of passenger safety, behaviour under shear and stress, fire smoke and toxicity, noise attenuation (simulation in an anechoic chamber), reduction of life cycle cost and ease of installation.

The rubber bellows are reinforced with fabric and noise reduction may be fine-tuned by varying the thickness of rubber layers and reducing leak effects.

RAIL VEHICLE GANGWAYS

Several types of rail vehicle gangways have been developed:

- Extruded profiles for high-speed trains

- Aerodynamic car-end profiles for high-speed trains

- Rubber gangway seals for high-speed trains

- Flanged UIC gangways for inter-city trains

ADDED-VALUE AND WORLDWIDE FIELD-SERVICE

Through its mastership of the complete gangway design and manufacture, (design of the function, validation by calculation (FEA), prototype realization, testing and qualification, series production including high process control and repeatability), Hutchinson Paulstra ensures optimised lifetime of delivered gangways.

With its worldwide organization, Hutchinson Paulstra provides to its customers a reactive field service and support.

REFERENCES

Complete gangways

- Metros: Paris, Mexico City, Lausanne

Floors and canopies

- Metros: Paris, Bilbao, Barcelona, Valencia, Santiago

- Tramways: Turino

- High-speed: TGV, ETR500