Vector Lifting is recognised throughout Australasia as the leader in heavy vehicle lifting equipment, particularly when it comes to railway maintenance equipment. With over 25 year’s experience in this specialised field, Vector Lifting has the engineering solutions for all types of materials handling problems.

Efficient maintenance and service facilities can mean the difference between acceptable and unacceptable profits. This is especially true when that facility is for light or heavy railway systems, urban transport authorities or long haul passenger and freight terminals.

VECTOR LIFTING SYSTEMS

All Vector Lifting systems are designed with a sharp focus on experience, quality and reliability, with safety also being a major consideration. Hence, our products not only inherit our extensive knowledge in the form standard features, but also offer a flexibility in design to suit specific client needs.

Over the years Vector Lifting has developed numerous pieces of equipment to best solve all types of lifting problems in the rail industry. Some of such products include:

- Underfloor lifting systems

- Railway jacks

- Bogie drop tables

- Bogie load system

- Bogie disassembly hoists

- Static and dynamic wheel balancing machines

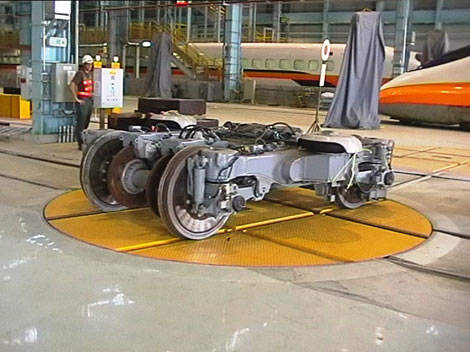

- Bogie and wheelset turntables

- Wheelset and axle rotators

Our projects have included full turn-key installations, with vector lifting taking responsibility from design to the fully operational finish. Such a project was completed for the Taiwan High Speed Rail Corporation in Kaohsiung, Taiwan, which as part of the facility included an under-floor lifting system capable of lifting simultaneously all 12 cars of an Electric Multiple Unit (EMU) trainset.

The innovation and engineering excellence found in all our products has contributed to Vector Lifting’s rapidly developing global reputation as a leader in design and construct projects for this market.

RAIL CAR UNDERFLOOR LIFTING SYSTEMS

Vector Lifting has developed numerous under-floor lifting systems to suit our client’s specific requirements. With a home position below rail level, workshop areas remain clear of machinery and trafficable for personnel and other machinery. Our systems remain flexible to vehicle type, capacity and size, so we can confidently offer a solution to almost any situation presented.

One of our more challenging under-floor projects was completed for the Taiwan High Speed Rail Corporation in Taiwan. An under-floor lifting system capable of lifting all twelve cars of an Electric Multiple Unit (EMU) train-set, a total of 300m and 720t of simultaneous lift.

The cantilevered system provides 2.4m of lift enabling removed bogies to pass under the raised railcar bodies for the full length of the track. In addition to the lifting requirements, the system had to offer stability during any occurring earthquake, which frequently affect Taiwan.

BOGIE DROP TABLES

Bogie drop tables enable the removal of a single bogie from a railcar without the need to raise the rail car body, resulting in fast and efficient bogie exchange. Body stands support the railcar body as the bogie is lowered into the drop table pit, where it traverses and is raised to an adjacent rail where repairs can be undertaken or a replacement bogie loaded for replacement to the railcar.

Projects are designed to suit each clients needs, including train type, unit capacity, workshop footprint and auxiliary functions.

RAILWAY JACKS

Railway jacks have been developed to facilitate safety, high efficiency and high productivity, performed on rail stock, electric and diesel multiple units, passenger trains and locomotives.

Through years of experience Vector Lifting has developed a range of fixed and mobile screw jacks which feature cantilevered extendable anvils for positioning and vehicle pick up, as well as double lifting jack systems which provide both vehicle lift and bogie removal.

With railway jack capacities in excess of 35t per jack, and the availability to link and operate multiple jack arrangements, total flexibility is offered to satisfy the client’s needs.