Based on advanced ultrasonic testing and machine artificial intelligence (AI)-assisted vision technologies, DTEC provides various solutions for railway safety. These can be installed at the trackside, in the service depot, and in the maintenance workshop.

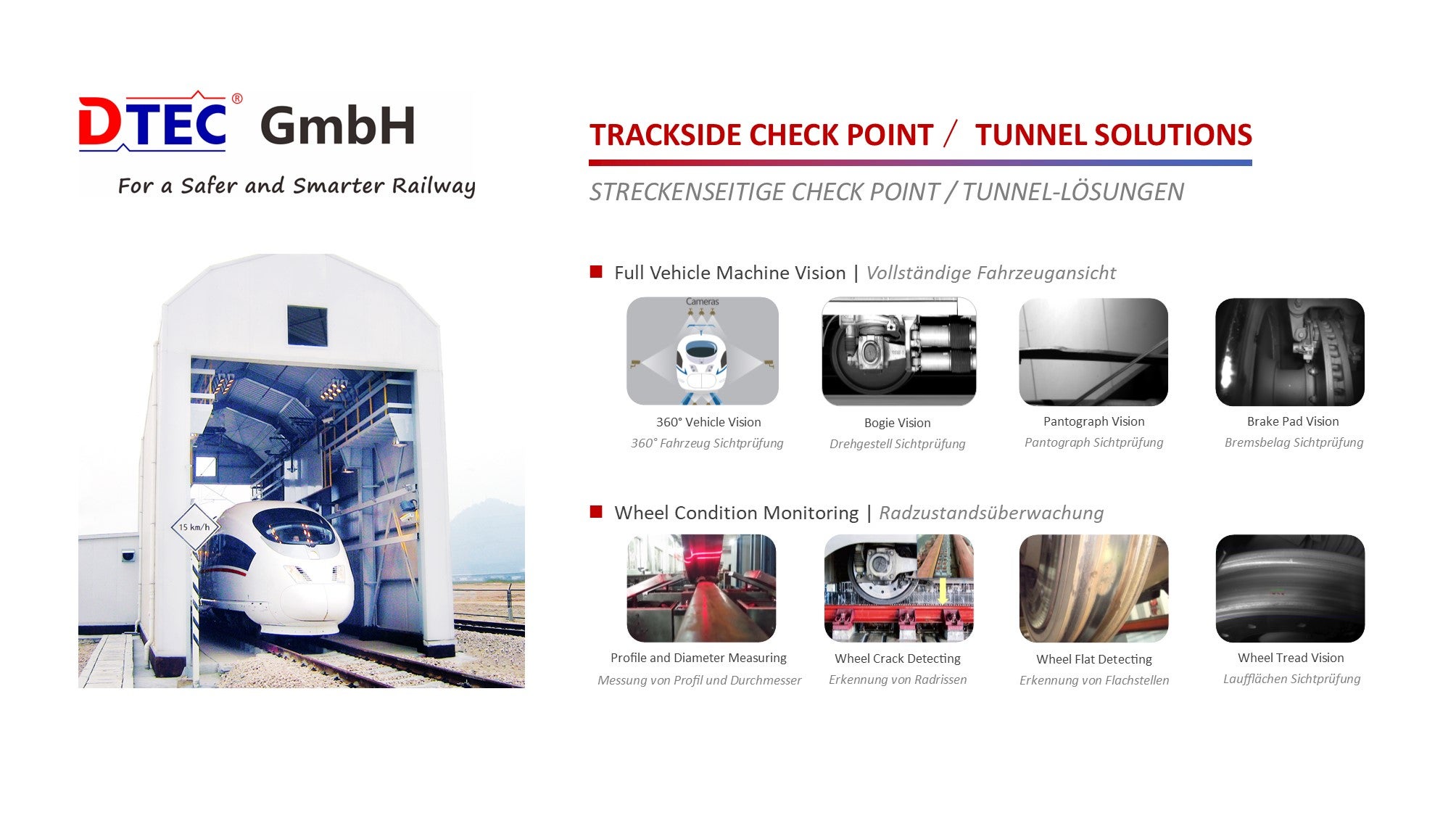

Trackside checkpoint/tunnel solutions for rail applications

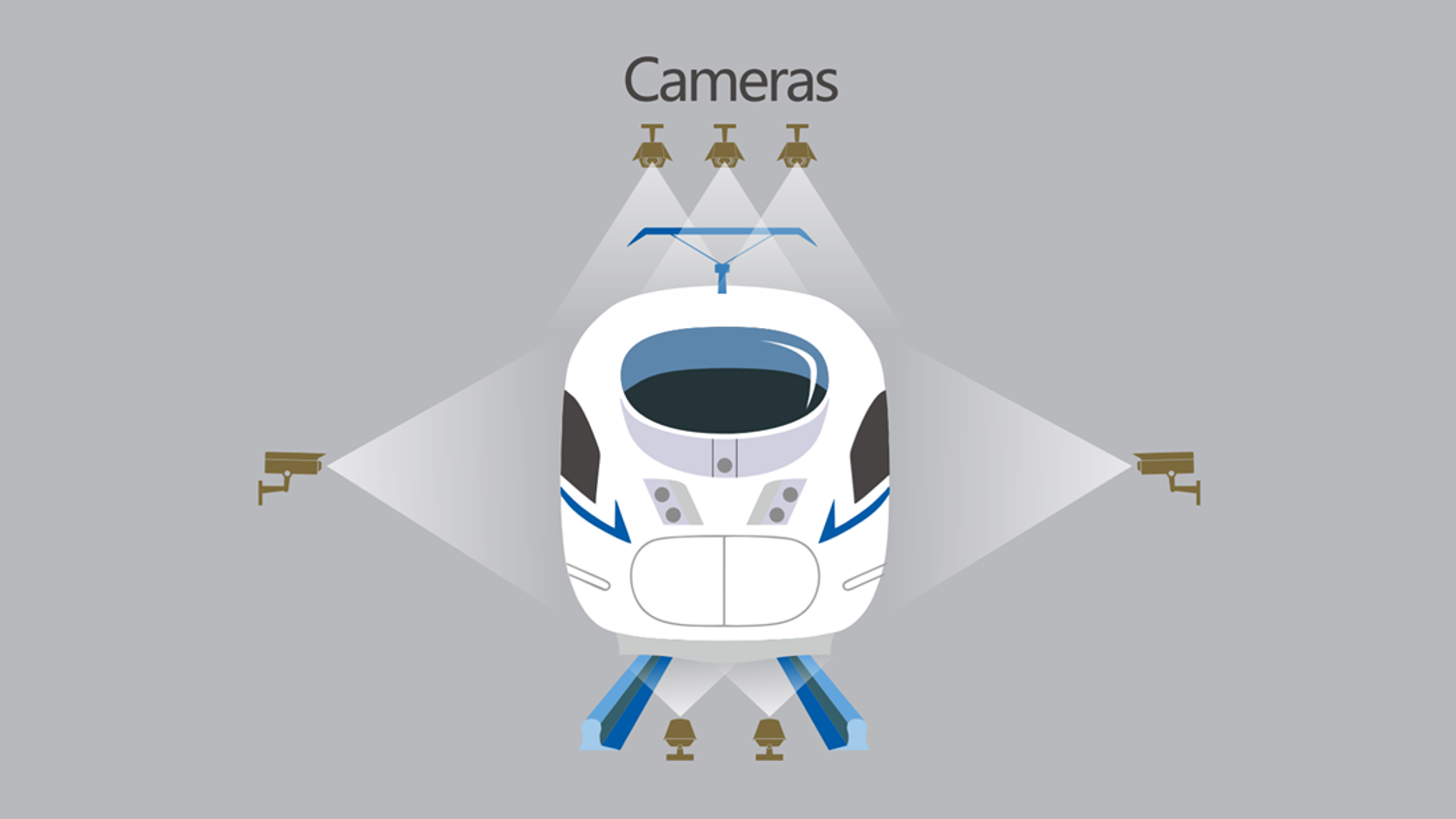

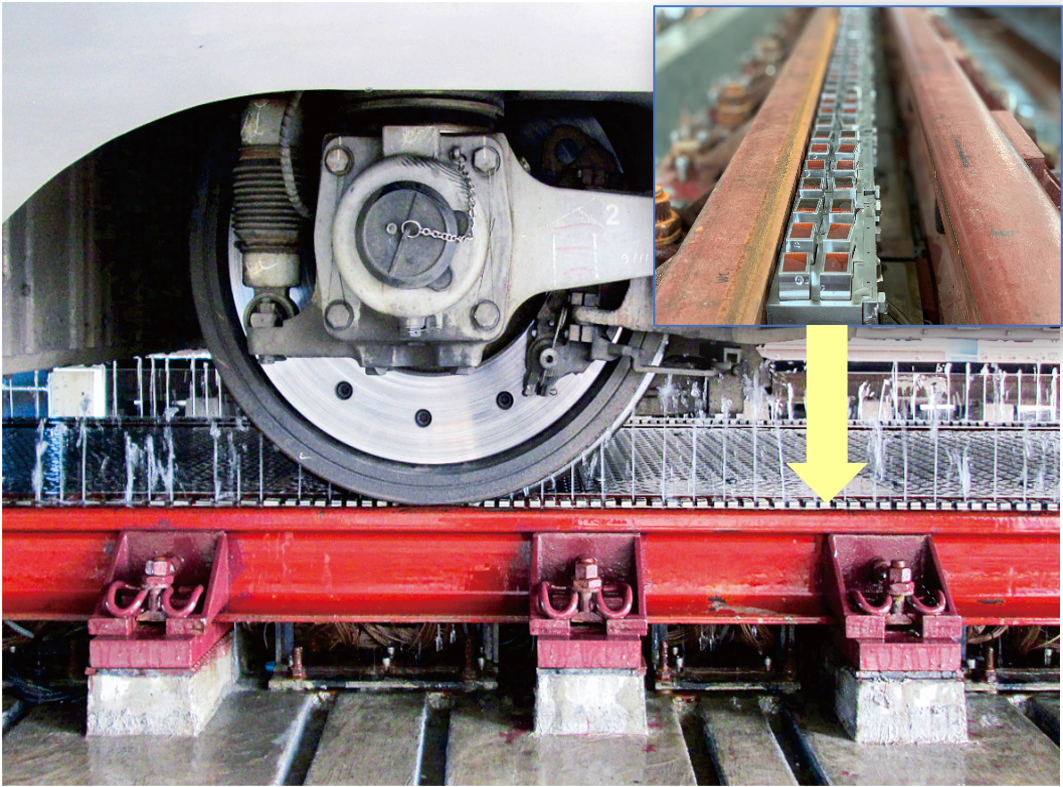

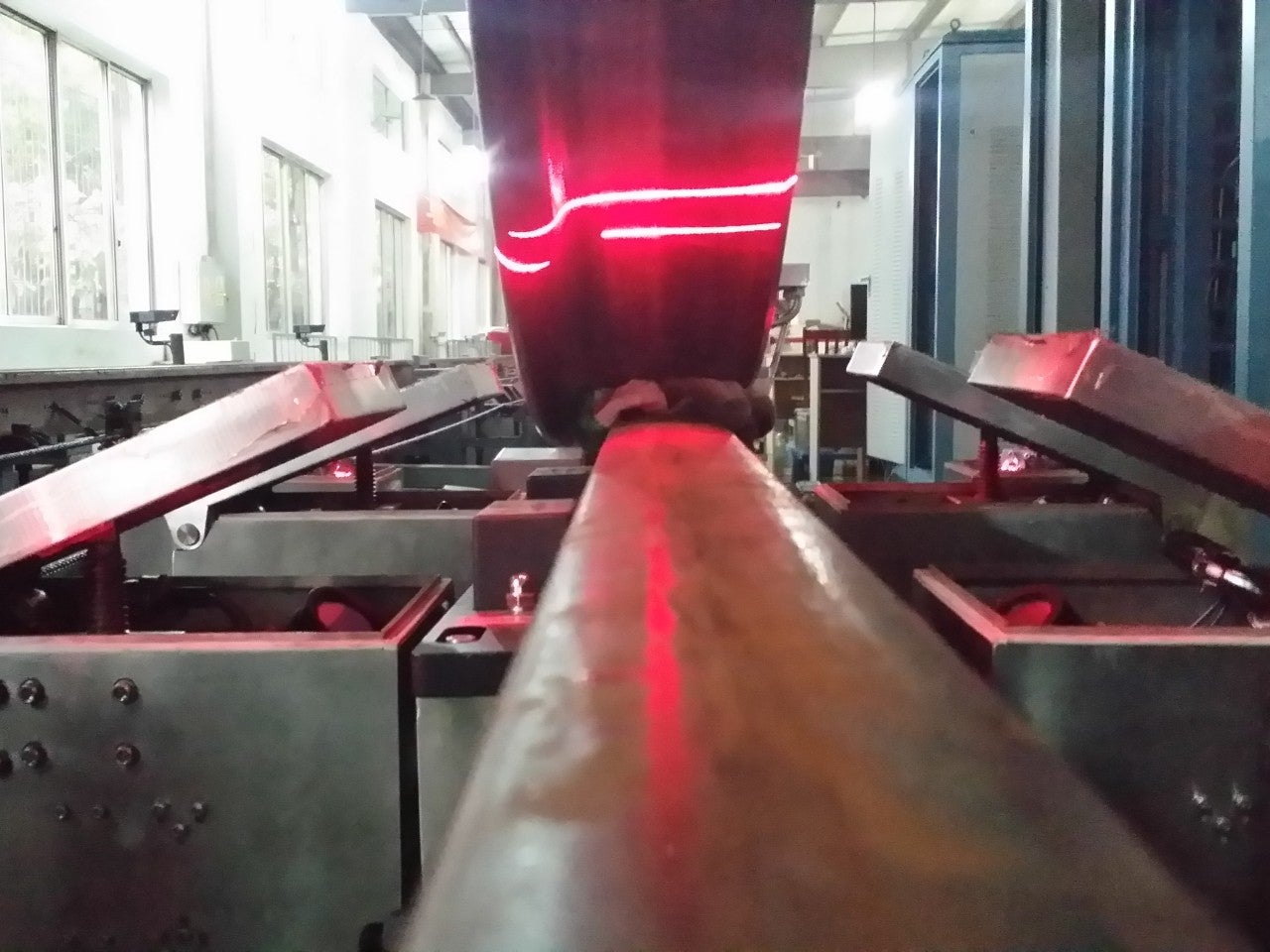

Installed at the trackside, checkpoint/tunnel systems consists of many modular function units and aim to carry out various inspections and measurements for a moving train. This includes monitoring of the wheel profile, detection of wheel cracks by ultrasound, measuring of brake pad and pantograph carbon strip, as well as fault recognition visible key components such as loss of bolts and foreign object detection by machine vision.

With years of development and application experience in the field, our trackside monitoring solutions have proved to be robust for use under various field conditions and railway vehicles.

Railway service depot and workshop solutions

Our Underfloor Wheelset Ultrasonic Testing System (UW-UT) is designed to perform highly efficient, accurate, and reliable wheelset vision inspections under the train.

With our Underfloor Vehicle Bogie Machine Vision System (UVB-MV) using AI, 3D imaging, and robotic automation techniques, we are moving asset management into a new era of smart maintenance.

We also offer mobile UT systems for hollow axles (HA-UT) and solid axles (SA-UT), as well as Dismounted Wheelset Ultrasonic Testing System (DW-UT), a gantry system widely used in rolling stock and freight maintenance workshops.

Ultrasonic testing systems for axles and wheels

In different maintenance levels, DTEC offers the most advanced automated Dolphin series ultrasonic testing systems for testing wheels and axles. Our wheelset ultrasonic testing systems can function when a train is in motion, or in a heavy maintenance workshop when wheelsets are dismounted.

DTEC also offers mobile wheel and axle testing systems working in a service depot.

Systems include:

- Trackside Wheel Crack Ultrasonic Testing System (TWC-UT)

- Underfloor Wheelset Ultrasonic Testing System (UW-UT)

- Dismounted Wheelset Ultrasonic Testing System (DW-UT)

Vision inspection systems for rolling stock

DTEC’s Eagle series machine vision solutions allow you to monitor and measure wheel profiles, wheel tread failure, brake pad and pantograph carbon contact strip wear, lost bolts, as well as other visible failures. Monitoring can be conducted in both motional and statistic conditions.

Systems include:

- Trackside Full Vehicle Machine Vision System (TFV-MV)

- Underfloor Vehicle Bogie Machine Vision System (UVB-MV)

Rail vehicle measurement and detection systems

DTEC also uses Owl series technologies to measure railway vehicle parameters and to identify defects. Condition monitoring systems derived by these technologies such as optical methods, laser imaging and thermal sensing are quite well developed and reliable.

Our Owl series system is the Trackside Wheel Profile Measurement System (TWP-MD).

Customised railway safety components and solutions

DTEC is a technology-driven company. Our experts offer tailor-made solutions according to your specific requirements, including case studies, pilot tests, system development, production, and application.

Contact us using the enquiry form on this page for solutions tailored to your application case.