CJSC Pskovelectrosvar is the largest flash butt welding equipment manufacturing company in Russia. Pskovelectrosvar applies innovative rail welding technology, which meets all Russian and European standards, to increase the productivity and quality of the finished product.

The main services that Pskovelectrosvar provides and areas that the company operates in include:

- The production of equipment for rail welding

- The design and manufacture of overhead and stationary welding machines, and auxiliary equipment for stationary production lines

- The design, building and turnkey commissioning of rail welding plants

- The production of welding machines for welding of turnout frogs and wits

- A provider of spare parts

Flash butt rail welding with oscillating fusion

The MCP-6301A welding machine is intended for flash butt rail welding with oscillating fusion in plant conditions. The machine centres rails according to their axis and to the height of the rail head before welding, and for the removal of burr from the perimeter of the joint immediately after welding. The operating control system is made on the basis of an industrial computer.

Contact joint welding with rail stretching

The MCP-12001A is designed for contact joint welding with rail stretching, flash removal directly after welding and work with PRSM rail types, such as P50 and P65. The machine’s control system is based on an industrial computer, which lets users set and monitor the parameters of the welding process. This provides the current information of the welding procedure, stores the information and outputs the log of every welded butt.

Straightening of cold rail joints

The YPCX-01 unit is intended for straightening cold rail joints to match the required geometry of the rolling surface and rail head. The unit straightens rails horizontally and vertically on a base length of 1,300mm, checking the rail bending at 750mm with laser sensors.

The unit can pass through insulating rail joints with combined metal-composite fishplates. The operating control system is made on the basis of an industrial computer, which makes it possible to register and store the welded joint straightening process.

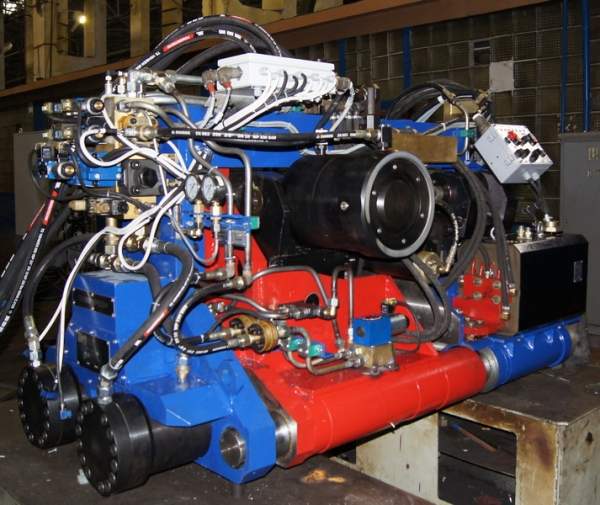

Flash butt welding of crossings

Welding machine MCC-15 001, for flash butt welding of crossings in stationary conditions, is designed for continuous or pulsating butt welding fusion of railway frogs. The machine is designed to work in difficult conditions that meet the performance of UHL location category 4, according to GOST 15150 and GOST 15543.1.

Flash butt welding by burning

The MCPO-8401 is intended for flash butt welding by burning off wits switches and rails, which are generally chromium and in stationary conditions, with the removal of the burr immediately after welding has finished.

Pskovelectrosvar has been involved in and completed a number of jobs in the past, including:

- Comprehensive modernisation of the technological lines at Russian railway welding plants

- Work at a rail welding plant in Uzbekistan

- Work at a rail welding plant at Lugovoye station in Kazakhstan

- Empresa Solcar from the Republic of Cuba

- The commissioning of a rail welding plant at the Ras-Lanuf production area in Libya

- The modernisation of a technological welding line for the Salyany rail welding company in Azerbaijan

- The building of the second technological line and equipment delivery for the Moscow underground system at Pechatniki station

- The delivery of equipment for the Baku underground system

- The delivery of equipment for Orsha station in Belarus

About CJSC Pskovelectrosvar

The quality management system of Pskovelectrosvar is certified according to EN ISO 9001:2008. The company is also authorised under the ISO 3834-2:2005 standard in the designing and manufacturing of electric equipment and metal, as well as butt welding in accordance with ISO 4063-24.

The technology fusion butt welding of rails R220, R260, R260Mn, R350HT to EN 13674-1 corresponds to European standard EN 14587-1. Certificates are issued by DVS ZERT, Dusseldorf, Germany.

Today, CJSC Pskovelectrosvar’s products are renowned in many industries, including aerospace, metallurgy, shipbuilding, nuclear power and construction, oil and gas.