Molytex is an innovative injection moulding company located in Denmark and specializing in the design and manufacturing of resilient rail fastenings and other components for applications such as signaling and rolling stock. The company was established back in 1965 and has leveraged on its experience and passion for discovering new solutions to become an international frontrunner within its areas of expertise.

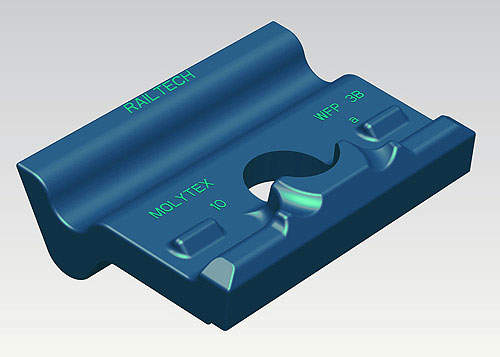

Molytex is a long-standing production and R&D partner of Pandrol Inc., supplying the world leader with durable plastic products such as sidepost insulators, toe insulators, as well as rail pads and other support parts. The company’s rail product portfolio includes the following:

Rail fastening systems and other rail components

Molytex delivers a variety of made-to-order components for rail fastening, including bushes, wedges, sidepost insulators, toe insulators, rail pads and other technical parts for the rail industry. The company holds crucial core competencies concerning design of rail plastic components, material selection, tool design and manufacturing, and state-of-the-art in-house robot-assisted injection moulding with engineering materials such as PA, EVA, and POM. Molytex’ technical competencies also include post-processing such as stress conditioning and advanced testing methods. The Company works with trusted international partners and makes every effort possible to exceed expectations every time.

Rail fastening systems R&D

Molytex has a high number of returning customers who value the innovation and reliable engineering skills of the company. Placing the customer at the center of R&D as well as manufacturing ensures high quality and cost-effective solutions for its rail industry partners. Molytex is committed to quality assurance across all functions, and the Company is certified under ISO 9001 as well as ISO 14001.

Cost-effective rail fasteners

In short, located in Northern Europe, Molytex delivers reliability, flexibility and innovation to railway clients world-wide. Molytex secures cost-effectiveness through automation, Lean principles, and close to 50 years of experience of integrated engineering.