Progress Rail Services, a wholly owned subsidiary of Caterpillar, is a leading supplier to the railway industry, operating one of the most extensive rail service and supply networks in the US with other locations around the globe. Head quartered in Albertville, Alabama, we serve our customers through a network of more than 140 locations across the US, Canada, Mexico, Brazil, Italy, Germany and the UK with more than 5,500 employees.

Engineering and track services for the railway industry

Our engineering and track services business unit offers a variety of cost-effective, sustainable solutions, including:

- Trackwork (switch and crossing)

- Flash butt rail welding

- Maintenance-of-way equipment

- Signaling

- Rail sales

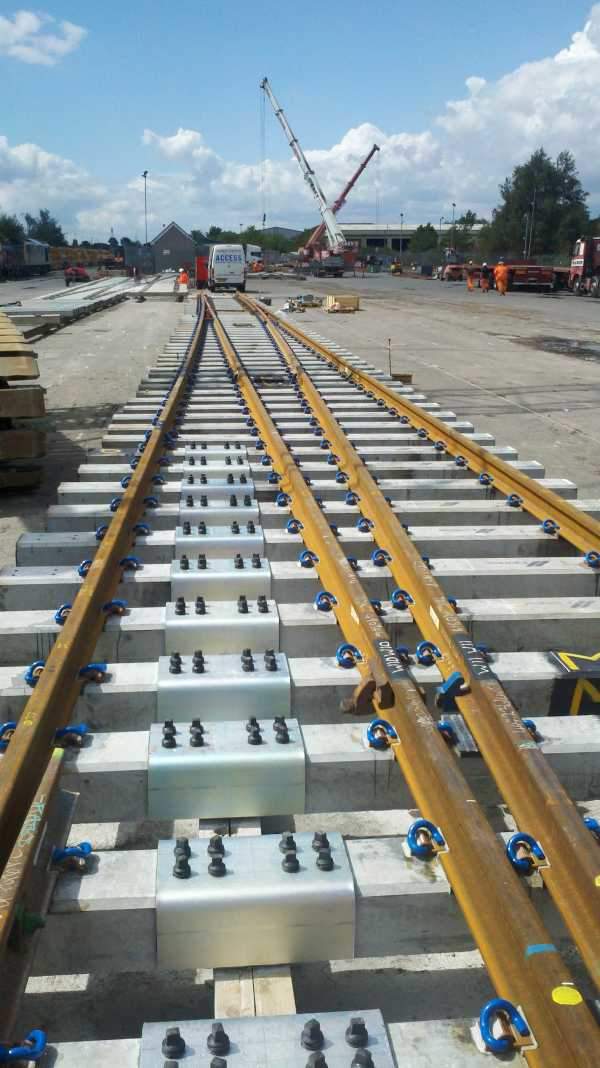

Turnouts, crossovers and crossing diamonds

Progress Rail supplies a complete line of trackwork products, which are certified to ISO 9000:2001 standards, including turnouts and crossovers, all turnout components, crossing diamonds and compromise rails from our six US facilities.

High-speed turnouts, manganese steel castings and bumping posts

In 2011, PRS purchased the trackwork manufacturing business of Balfour Beatty Engineering, with five facilities in the UK. The company now operates as PRS UK, lending trackwork expertise and providing extensive offerings, including high-speed turnouts, manganese steel castings and bumping posts. Progress Rail’s extended trackwork offerings enable us to focus on enhanced rail engineering and coordinate customer focused efforts through our numerous facilities for all your S&C needs.

Fixed-plant rail welding products and mobile welders

A subsidiary of Progress Rail, Chemetron Railway Products has been designing, building and operating rail welding systems since 1957. Chemetron provides products for fixed-plant rail welding, in addition to building and selling mobile welders. Our weld systems have made more than 25 million welds. We provide welding equipment for use around the world.

Our CHEM180-ton DC intrack welding head is capable of making closure welds up to a 10in gap without a separate puller unit. The DC weld heads allow for greater efficiency, thus allowing a smaller generator with more welding current than competitive AC machines.

Our mobile welders are designed to equal or exceed the quality and reliability of fixed plant welds. Our mobile welder combines the industry’s most advanced welding technology with the reliability and consistency that Chemetron designs into all of its welding systems.

Railway maintenance-of-way equipment and ballast regulators

Also part of Progress Rail, Kershaw Manufacturing produces a complete line of railway maintenance-of-way equipment. Developed in the 1940s, Kershaw’s Ballast Regulator remains its iconic product, with more than 3,000 Kershaw regulators in service around the world. Kershaw offers other products for ballast profiling, track dressing, tie equipment, ballast cleaning and vegetation control.

Signal design services and products

Progress Rail’s signal division provides signal engineering for positive train control (PTC). The signal division features a broad array of signal design services, including a full line of signal products, an experienced design staff, complete turnkey solutions, and installation and maintenance contracting.

Hot wheel and hot box detectors, data acquisition systems and draggers

As part of the signal division, Progress Rail Inspection and Information Systems designs, manufactures and sells hot wheel and hot box detectors, data acquisition systems, draggers and other related inspection products for the global freight and passenger rail segments. Our facilities in Germany and Italy supply similar products designed for high-speed railways, including the FUES and crossing guard products.

For more information on these and other product offerings, visit the Progress Rail Services website.