Sonneville International Corporation (SIC) was incorporated in 1981 to pursue the worldwide development of the track system, which was originally designed by Mr Roger Sonneville.

Starting in the 1960s Mr Roger Sonneville together with SBB developed the first slab track system based on booted bi-block ties embedded in concrete. This system was one of the first slab track systems in the world and has evolved from bi-block ties for ballast track to the booted single block system low vibration track (LVT) in use today. The outstanding system performance and the extensive experience of SIC in the railway industry has seen its LVT system installed in three of the longest railway tunnels in the world.

To improve the vibration attenuation of LVT, standard SIC designed a new generation of LVT called LVT high attenuation (LVT HA). This latest innovation reduces the costs of lowering mechanical vibrations and noise emissions.

In 2009, after almost 30 years and two generations, Roger Sonneville’s son, Bernard, sold 100& of his SIC shares to Vigier Holding. This made SIC a sister company of the European licensee, Vigier Rail. To use as many synergies as possible SIC has moved to Switzerland and operates under its new name Sonneville.

LVT systems

The LVT system has been constantly improved and modified to meet client demands. As a designed system the performance of LVT is customised according to specific project requirements.

LVT provides design and cost advantages, which makes it very competitive against other systems and heavily used.

Single-block LVT systems

From its origins as a bi-block sleeper in a ballast bed, the LVT system has been developed into a single block system. It has a concrete block in a rubber boot and a block pad embedded in slab concrete.

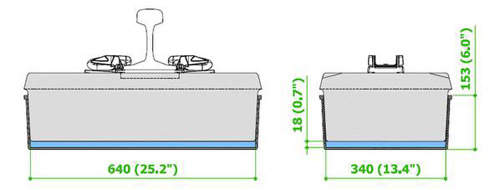

The latest step in the development of the LVT system has been the implementation of LVT HA. With a 30& wider block and a 50& higher block pad the vibration attenuation is significantly improved.

LVT for switches and crossings

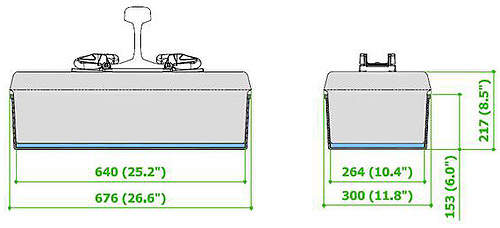

The installation of LVT special blocks for switches & crossings (S & C) provides a consistent track modulus and track behaviour. All types of S & C and fastening systems can be mounted using a combination of five different LVT block sizes.

LVT installation

Different ways of installing the LVT slab track system are possible and Sonnville’s engineers will work with you to find the most efficient and accurate installation procedure for your needs.

LVT maintenance

Most of the existing slab track systems are hard to maintain and finding replacements can cost time and money. With the LVT system an efficient replacement and adjustment can be achieved.

LVT renewal

By replacing ballast tracks with the LVT slab track system, it will give railway operators the ability to provide constant service and reduce costs.