Amsted Rail manufactures undercarriage components for heavy haul freight railcars and trains. Our company offers innovative components and integrated bogie systems to meet the needs of the global heavy haul freight industry.

Freight shippers, railroads and lessors around the world have come to rely on Amsted Rail to develop products that can haul heavier loads over greater distances, with improved reliability and performance, as well as a focus on meeting the operating challenges of each region. With a long history of industry innovation, Amsted Rail was the first to meet the Association of American Railroads (AAR) M-976 performance standard.

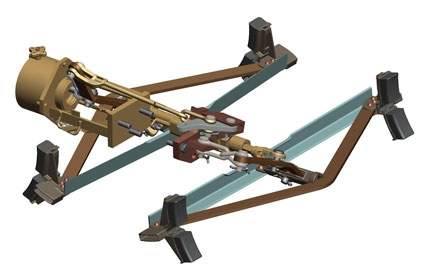

Lightweight, heavy haul truck car assemblies

Amsted Rail manufactures one of the world’s the most reliable truck car assemblies. Through our ASF-Keystone® division, Amsted Rail designs and manufactures a range of complete truck systems to satisfy every application, thrive in every environment and meet every challenge. All systems are supported by our 100-year AAR record for proven reliability.

Through our patented lightweight process, ASF-Keystone has been producing durable, heavy haul, lightweight truck systems for customers from Brazil to Burma. By combining higher-yield B+ steel with a proprietary coring process, we are able to reduce an average weight by as much as 800lb a carset without sacrificing strength. ASF-Keystone trucks consistently exceed the million-mile barrier, even in the ever-changing heavy haul freight transportation industry.

Tapered roller bearings for rail freight cars

Amsted Rail founded Brenco® in 1949 to manufacture bronze journal bearings for railroad freight cars. It obtained conditional AAR approval for the tapered roller bearing in 1959, and is Brenco’s best-known product.

Supplying the majority of the North American original equipment manufacturers (OEM) market, millions of our bearings currently provide dependable and reliable service in one of the world’s most demanding environments. Brenco’s reputation for quality, reliability and dependability are standards for all of the products the company manufactures.

Customised springs for railways

ASF-Keystone® spring manufacturing is differentiated by its excellent process control, which assures consistency of dimensional, metallurgical and functional properties in final products. Our engineers have extensive experience in designing customised springs for the most demanding requirements. All ASF-Keystone spring manufacturing processes include shot peening and heat-treating.

ARR-approved braking systems and components

From AAR-approved truck-mounted and body-mounted braking systems to a complete line of AAR-approved hand brakes, empty load sensors and brake cylinders, Amsted Rail-Faiveley’s global manufacturing capacity ensures a quick and efficient response to our customer’s needs.

Customised pellet car systems

Our comprehensive product line allows clients to customise and coordinate all of their pellet car needs through a single supplier. Amsted Rail provides the market’s most versatile, Environment Protection Agency (EPA) approved pellet outlet gates and hatch covers to a complete line of AAR-approved empty-load devices, slack adjusters, hand brakes, truck mounted brakes (TMB) and bogie assemblies.

Rail wear prevention products

Amsted Rail’s Hollube® and Hollamax™ wear prevention products are made with an advanced plastic that outlasts steel and reduces wear by up to 88%. Whether it is wear on brake beams, center plates or bowls, couplers, yokes or brake rods, Amsted Rail’s wear prevention products can save money in replacement costs through their built-in lubricity.

Friction shoes and damping systems

Amsted Rail has a long history of truck development and innovation, ensuring the quality and performance that you have come to expect from an industry leader. Our systems engineering design approach allows for optimised solutions for both performance and longevity of the friction damping system. Our highly engineered friction damping systems improve ride quality and truck performance, providing longer lifecycle for your railcar components.

Amsted Rail’s expertise ensures all friction damping systems are optimised for both performance and longevity. Our highly engineered friction damping systems improve ride quality and truck performance, providing longer lifecycle for your railcar components.

Customisable end-of-car systems

Our comprehensive product line enables clients to customise all their end-of-car system needs with a single supplier. From the market’s toughest integral cast draft sills and gears to a full line of AAR-approved cushioning units, drawbars and couplers, Amsted Rail provides integrated systems that are engineered to effectively reduce impact stress.

Railroad axles

Through its AXIS Worldwide operation, Amsted Rail manufactures railroad axles to the most stringent standards in the world. AXIS produces more than 50 different types of railroad axles and can manufacture virtually any type of railroad axle used in the industry.

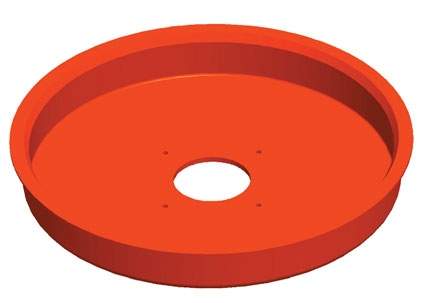

Micro-alloy wheels for train cars and carriages

The Griffin® wheel brand has been at the forefront in wheel design, manufacturing innovation and reliability for more than 100 years. Now an integral part of Amsted Rail, Griffin is even more committed to industry-leading safety and innovation. The latest advance is Griffin’s patented Micro Alloy® wheel, which provides increased strength at higher temperatures, resulting in fewer wheel-set removals and a dramatically longer wheel life.