Hanson Springs is a spring manufacturer that manufactures an unrivalled range of compression springs, tension springs and torsion springs used extensively throughout the railway industry. Springs are supplied in wire sizes of 0.1mm to 80mm bar, and can be ordered in quantities from one-offs to tens of thousands.

Hanson Springs has vast raw material stocks in a range of materials for producing its compression springs, tension springs and torsion springs: these include carbon, alloy and stainless steels, inconel, hasteloy, elgiloy, titanium, monel and copper alloys.

In-house heat treatment, powder coating and non-destructive testing are supplied by 24-hour production facilities for fast turnaround. The company is ISO 9001:2008 certified.

Precision and coil springs for bogie suspensions, buffers, signalling and track parts

Hanson Springs has been supplying the world with quality, UK-manufactured springs since 1967. Coil springs wire sizes from 0.1mm to 80mm can be coiled into precision springs to suit bogie suspension, buffers, signalling, track parts and many other applications in the rail industry.

Substantial raw material stocks and round-the-clock production allow Hanson Springs to react quickly to meet the needs of a diverse customer base.

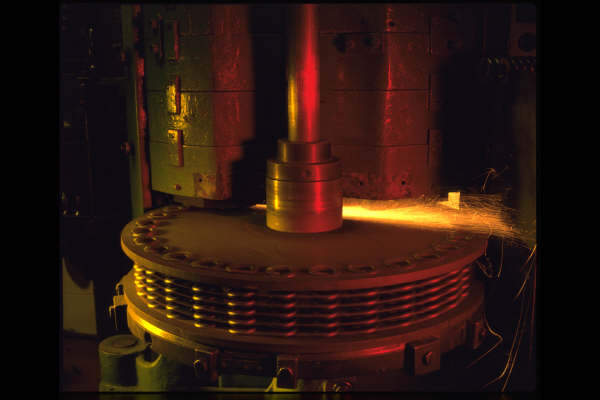

Spring heat-treatment, powder coating, aluminising and non-destructive testing

Hanson Springs has an in-house heat-treatment, powder coating and aluminising plant for its springs, and applies non-destructive testing (NDT) of two types: magnetic particle inspection NDT and dye penetrant inspection NDT. These facilities afford the company complete control over the entire manufacturing and validation process.

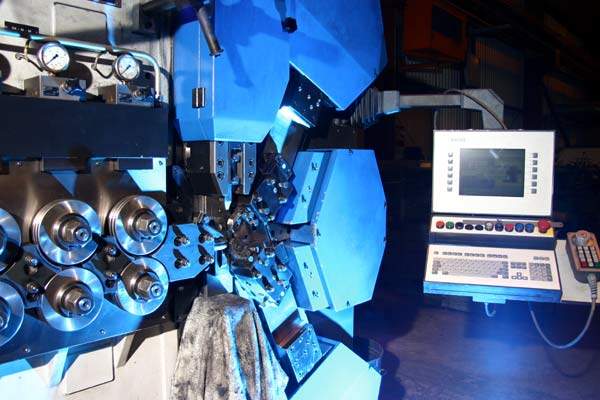

Continual investment in the very latest technology has enabled Hanson Springs to develop into one of the largest spring manufacturers in Europe.

Design, development and prototyping of rail springs

Hanson Springs designs, develops and prototypes rail springs for many applications, and regularly looks to reduce costs whilst maintaining its trademark: namely, quality.

Apprentice springmaker recruitment and training

Experience is key to a successful business, and within the Hanson Springs team are some of the most knowledgeable and skilled people in the spring industry.

Many of the 170 UK employees have in excess of 25 years’ service, but Hanson Springs are forward thinking and regularly recruit, train and most importantly retain apprentice springmakers – which is now very rare in the spring industry.

As a family-owned business, Hanson Springs gives a particularly personal level of service – a refreshing change when many competitors are now part of large and often non spring-related corporate groups.

Rapid-delivery rail torsion, tension and compression springs

Substantial raw material stocks, 24-hour production, and in-house heat-treatment, finish and NDT processes allow Hanson Springs to achieve very rapid turnaround.

Cost-effective rail torsion, tension and compression springs

Hanson Springs use their own spring design software, which has been developed to accurately predict spring performance. This allows for optimised and therefore cost-effective spring designs.

Extensive investment in production facilities gives the lowest possible manufacturing costs, which Hanson are pleased to pass on to their valued customers.

High-quality rail torsion, tension and compression springs

Quality is expected and not open to negotiation. Hanson Springs’ products stand head and shoulders above its competitors’. The attention to detail at every stage – including enquiry, order processing, raw material validation, production and despatch – is second-to-none.

Full traceability of raw material, production and heat-treatment records allow Hanson to supply springs for the most demanding applications with complete confidence.

With two manufacturing plants in the UK, a US distribution facility and a European office in Milan, Hanson Springs is never far away and can give you the service your business needs.