Katsa Oy provides power transmission components and systems, high-accuracy gearwheels and tailor-made gearboxes for specific rail applications.

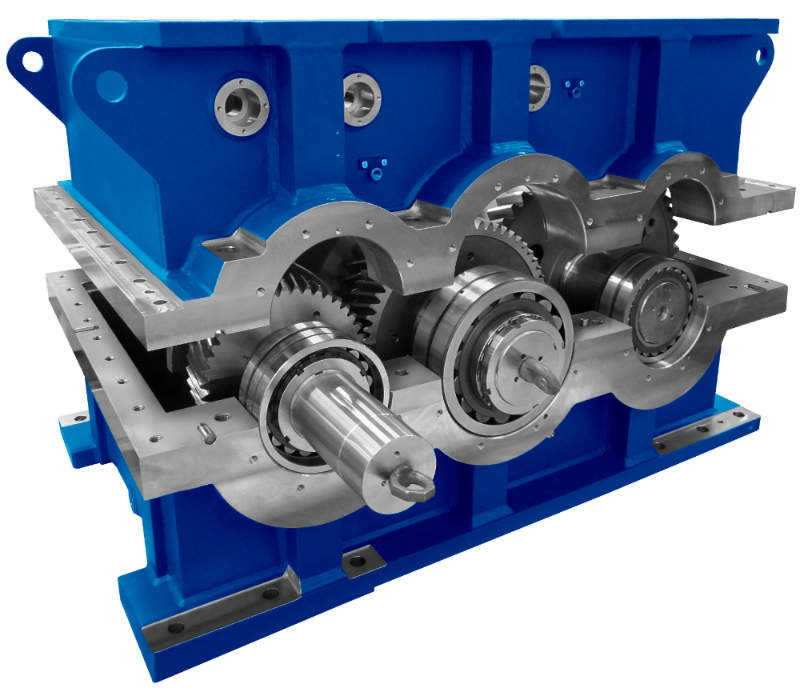

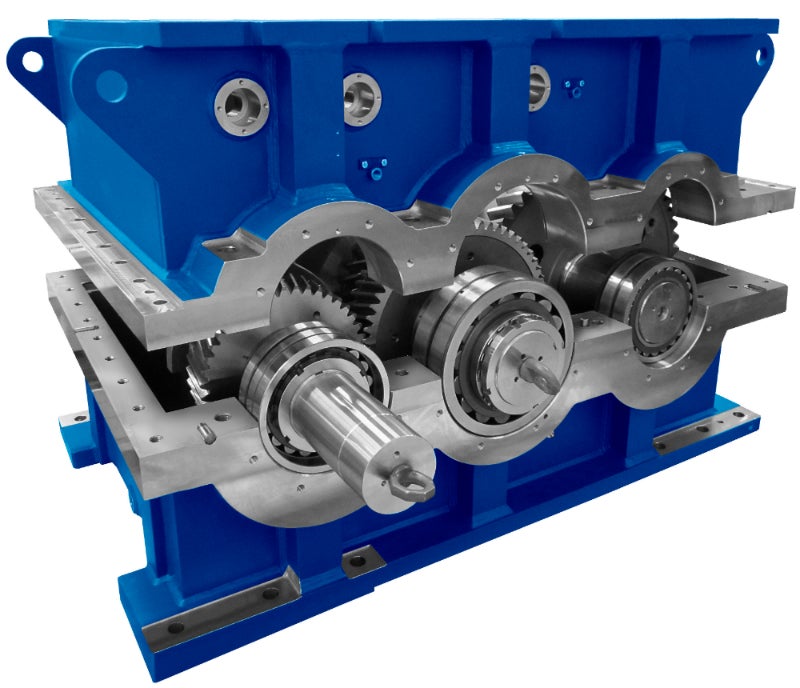

Gearboxes for industrial applications

Katsa gears and gearboxes are used worldwide for a variety of purposes, including wind turbines, marine engines and propulsion systems, railway applications, mobile mining machines, and army vehicles.

We are able to provide clients with R&D services, from full gearbox design to re-engineering components for refurbishment. Gear calculations, finite element (FE) analysis and gearbox simulations are all performed by our experienced designers.

We have seven Pfauter & Reishauer gear-grinding machines and more than ten Pfauter gear-cutting machines. We are fully independent regarding heat treatment, with four Ipsen furnaces weighing between 1,000 and 5,000kg.

Gearwheels for the railway industry

Our gearwheels are capable of grinding to a depth of 1,600mm, and cutting up to 2,500mm. They also feature worms with a size of up to 350mm, and worm wheels up to 2,500mm.

Tailor-made gearboxes

Gearboxes can be tailor-made according to the client’s specifications. They come with a wide range of features, including:

- Output torque up to 300kNm

- Speed reduction ratio area from 1,800:1-2:1

- Speed-up ratio area from 1:2-1:10

- Maximum axial shaft distance: approximately 800mm

- Input power: approximately 2MW

All gear types and combinations are available.

About Katsa

Katsa’s skilled, experienced workers use ISO-certified QHSE systems to develop our products. Our intranet comes with high-quality instructions to allow for quick, easy accessibility across the board.

Katsa collects data during the manafacturing process, which allow us to constantly improve our services. For example, air-conditioning is now included at the end of the process to mantain a constant grinding temperature, and thereby achieve the highest possible accuracy.

Gear flanks for all Katsa products are inspected using CNC-controlled special gear-measuring machines (geometrical measurements are also possible).

All products endure a separate final inspection and classification. They also feature an individual serial number, the base of quality control and 100% traceability.