Nencki is a leading Swiss manufacturer of bogie testing and maintenance equipment and for machinery for stationary rail welding plants.

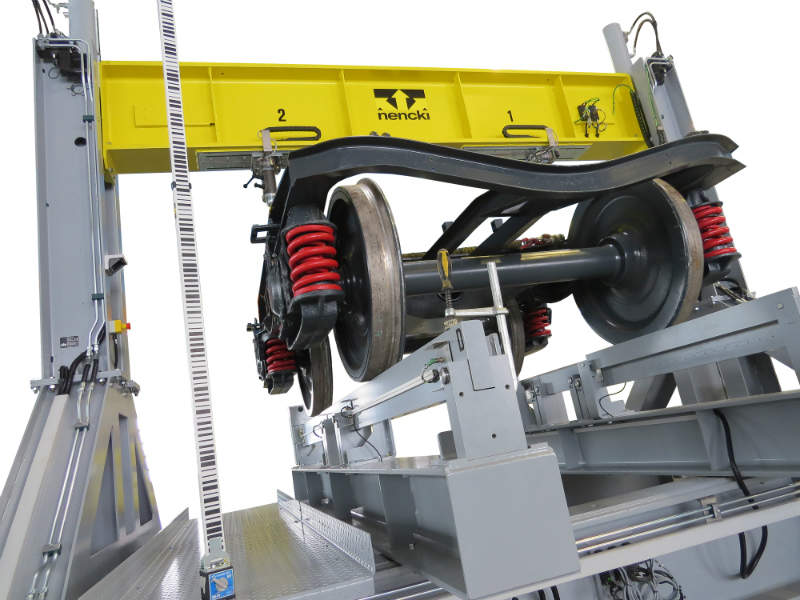

Computer-controlled bogie test stands

The product range includes machines for testing of two and three-axle bogies for coaches and locomotives.

Accurate testing and adjustment of wheel loads and bogie geometry help to improve passenger comfort and avoid wear of the rail bogie and derailing accidents. All of this help to lower operating costs.

The Nencki bogie test stand is available with the following test features:

- Wheel load

- Calculation of shim plates

- Axle distance and parallelism

- Wheel shoulder (wheel back-to-back distance)

- Test in combination with tilting technology

- Test in combination with radial (wheel steering bogies) technology

- Leakage test of the air bolster

- Wheel diameter and run-out

Many more exciting features are also available.

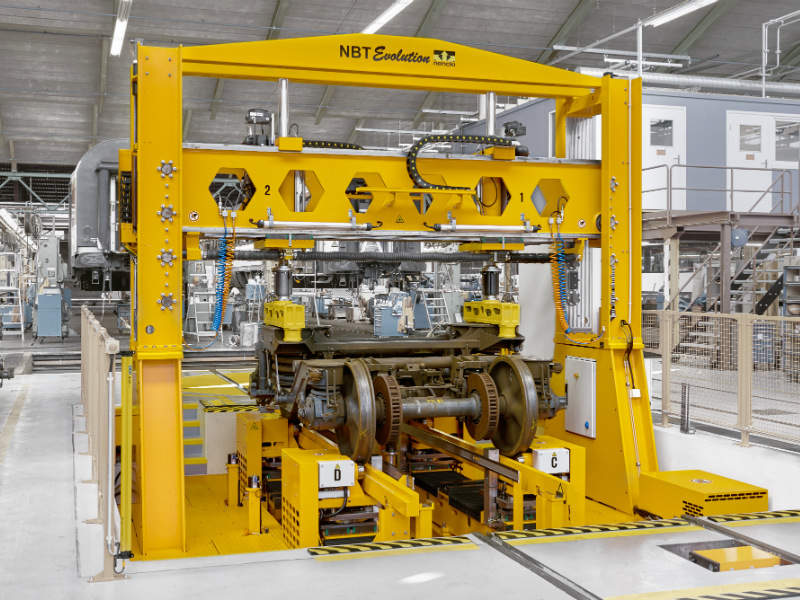

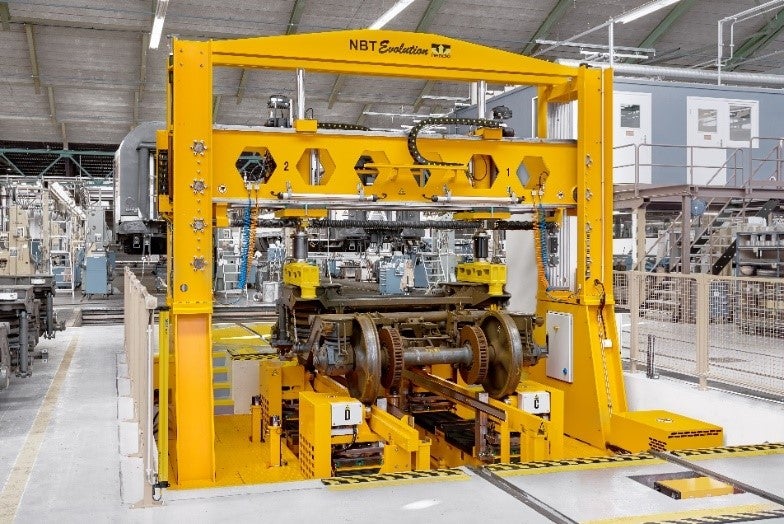

Integrated maintenance of railway bogies

The Nencki integrated bogie workshop features seven testing stages, namely the wheel weighing facility, bogie exchanging system, bogie lifting system, assembly press yoke, mobile press, spring test press, and the damper press test.

The wheel weighing facility tests vehicle safety according to EN 14363 by simulating an uneven track and warped curves. This is designed to examine the potential of derailing.

Bogie exchange and lifting systems are used in replacing single bogies that may have failed tests, elevated up to 1.7m-high.

Click the link in the company details to view a video of the integrated bogie workshop.

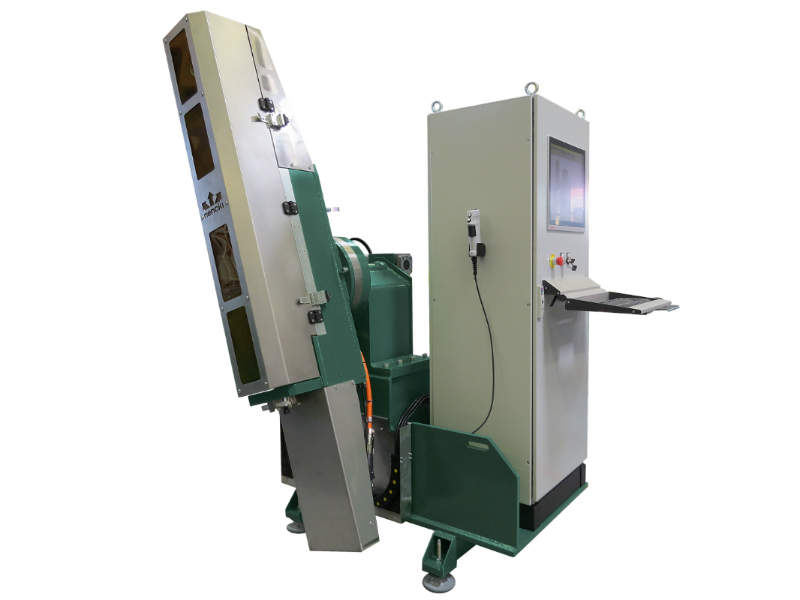

Computer-controlled spring test presses

Nencki offers solutions for coil, metal-rubber and leaf springs as well as solutions for testing of complete primary suspensions. Its fully computer-controlled machines can be used for the testing of:

- Axial stiffness

- Transversial stiffness

- Bowing angle and distance

- Deflection diagrams

- Other spring-specific test parameters

Spring testing machines from Nencki are user-friendly with solid construction, optimised for use in small spaces. Test processes, functions and measurements can be controlled through an industrial computer module in a fixed electrical cabinet.

Wheel weighing facility

Safety against derailment is a primary concern for locomotive and rolling stock manufacturers and rail operators alike.

Nencki’s wheel weighing facility allows for the measurement of individual wheel loads and unloading in a twisted-track derailment scenario.

The test is performed to the regulations of the EN 14363 standard, is fully automatic and can be completed in less than 30min.

Damper testing

Nencki developed the damper test press for measuring damper force in relation to the speed.

The damper test stand is a self-lubricated, user-friendly stand, with fully automatic adjustable angular positioning of the damper. Test processes can also be programmed into an integrated computer.

Made by Nencki in Switzerland

All Nencki products are manufactured in Switzerland. Nencki has its own departments with skilled staff for mechanical, hydraulic, electronic and software engineering, as well as manufacturing facilities for machining, welding and assembly and an international after-sales service organisation. Nencki operates in accordance with international standards such as ISO 9001.

Nencki has regional offices worldwide, and is always interested in additional distribution partners.