FERODO-branded friction products are known to ensure reliable stops. Founded in Chapel-en-le-Frith (UK) in 1897,

FERODO Railway was the first company to supply the London Underground (1907) with blocks and the first company to

manufacture brake pads for railways.

High-grade organic LCC and high-temperature brake pads

FERODO offers extremely high-grade organic LCC and high-temperature brake pads. The pads feature excellent friction

stability and higher friction material flexibility, which helps to reduce the formation of hotspots on the brake discs. All of these characteristics ensure that the friction surface combinations improve the durability of the brake pads and brake discs. In cooperation with railway operators, brake system suppliers and rail vehicle manufacturers, the Federal-Mogul team develops on optimised organic friction surface combinations for cast iron and steel brake discs, while taking into consideration customer technical specifications.

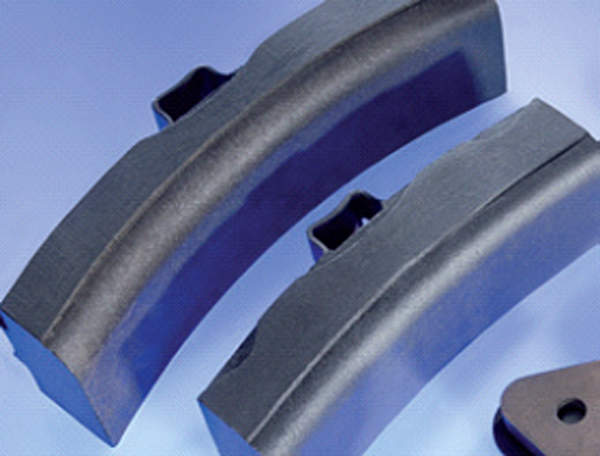

Optimised block wheel friction combinations

FERODO also offers optimised block wheel friction combinations. A wide range of asbestos-free organic L, LL blocks for direct cast iron replacement are available. K-blocks, which are suitable for train, metro, locomotive and freight applications are available in many different shapes.

Organic railway disc brake pads

Ferodo offers a wide range of asbestos-free organic brake pads from low / medium up to high temperature applications. Advantages and features of Fedoro products include:

- Leading supplier of LCC friction products in the railway market

- Conformable pads to reduce hotspots, noise, disc and pad wear

- Friction stability over a wide range of temperatures, clamp forces, axle loads and speeds

- Suitable for all types of cast iron and steel wheel and axle-mounted discs

- Suitable for passenger trains, freight, metro and tram applications

Sinter railway disc brake pads

Ferodo’s sinter railway disc brake pads offer the following advantages:

- Numerous sintered materials available

- Conformable backplate design reduces hotspots, disc and pad wear

- Friction materials for different duty levels available

- Friction stability over a wide range of temperatures, clamp forces, axle loads and speeds

- Suitable for wheel and axle-mounted discs

- Suitable for passenger trains and locomotives

- Unique sinter triangle segments provide maximum contact surface

- Conformable steel backplate for better disc temperature distribution

- UIC-approved sinter material available

Organic railway brake blocks

Ferodo brake blocks provide:

- Excellent block life

- All materials have very good dry and wet performance, even under extreme weather conditions

- Suitable for use on all standard types of steel wheels – no adverse effects on wheels

- Significantly reduced rolling noise, lighter than cast iron blocks, offer more than doubled service life and improve wheel durability

- Blocks are available in UIC standard shape, other references are available on request

- UIC approved block materials available

Federal-Mogul offers friction products for any application, giving cost-effective options to support your business. The FERODO team draws on the experience and support from the company’s worldwide development engineering

expertise in the passenger car and truck sectors. This collaboration ensures the highest possible efficiencies to develop the best friction products for rail vehicles.