Miner Enterprises is a leading designer, manufacturer, and supplier of wagon components to railroads, locomotive and freight wagon builders, private wagon companies and repair shops in 56 countries around the world.

Since 1894, Miner has focused on improving the performance and value of its products and the freight cars that use them through frequent testing, in-depth service analysis and industry-related experience spanning 130 years.

Miner’s experienced team of engineers and technicians work closely with its sales and marketing departments to provide high-quality products, which meet or exceed the changing needs of the marketplace.

Buffer and drawgear springs

Miner’s TecsPak® buffer and drawgear springs comply with EN specifications EN-15551 and EN-15566 and can be used either as retrofits in existing housings or in new buffer constructions.

The TecsPak polymer material developed by Miner is lightweight yet can withstand extreme loads. It absorbs far more energy per weight and volume than its closest competitor and has high life expectancy — up to: 20 times longer than urethane, ten times longer than rubber, and five times longer than steel springs. Springs made of TecsPak are maintenance free, never need adjustment, operate in temperatures ranging from -40°C to +50°C, and are available with ultraviolet protection.

Draft gears

Miner friction draft gears absorb 35%-40% more energy than non-friction gears for higher impact protection. At 123kg, the TF-880™ is the lightest high-capacity draft gear available and has been applied to all types of wagons carrying a gross rail load of up to 130,000kg. Yet the service-proven friction clutch and TecsPak spring package combine extra-heavy-duty protection and less operating slack for reduced wear in both mixed consists and heavy haul unit trains.

Side bearings

Miner’s constant contact side bearings, with their TecsPak elastomer pads, are designed to reduce bogie hunting, provide maximum vertical energy absorption to help control wagon body roll and reduce component wear on all types of wagons.

While friction from constant contact side bearings acts to resist bogie rotation in curves, long travel constant contact side bearings have been found to actually improve curve negotiation. Long-travel (16mm vs the standard 6mm-8mm) side bearings provide enough flexibility to decouple the wagon from track cross-level differences both in curves and on irregular track. This results in better wheel load equalization and lower lateral wheel loads on the rail.

Trough hatch covers

DuraShield™ covers are made with an aluminum skin and a solid polyethylene core, which is more durable and lighter in weight. The covers accommodate most 24in trough designs and are available in all standard lengths in both round and square end-cover configurations.

Drainage outlets

Miner’s heavy-duty outlets offer reliable, trouble-free discharging of grain and other foodstuffs, dry bulk chemicals, sand, cement and other commodities. The AutoLOK™ II’s full perimeter seals combat leakage of very fine particles and door supports minimise deflection.

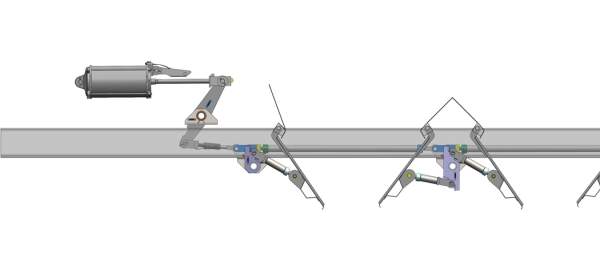

Unloading systems

Miner’s AutoMEC system can empty wagons containing coal, wood chips or other bulk commodities in less than 20 seconds while stationary or moving at up to 4.8km/h. Its innovative air-operated, single and double-link door linkage system maximises reliability, minimises door adjustments and reduces maintenance costs over the life of the wagon.

Discharge systems

The AggreGate® was developed to afford easy and versatile delivery of ballast to the track structure. Ballast can be selectively discharged inside the rails, outside the rails, or both simultaneously. The gates are available for manual or remote control and can be configured with manual, air or solar-powered operation.

Brake beams

Our unit style brake beams are designed to minimise weight and reduce brake shoe consumption by up to 20%, resulting in an extended service life. Notched brake heads reduce beam binding for a more consistent performance and feature easy brake shoe key insertion, as well as incorporate a key-retaining lock. In addition to beams, Miner also offers steel side-frame wear plates and other brake beam components.

Rail running boards

Miner Grating Systems provides repair shops and wagon builders, and standard and custom configuration running boards for all types of railcars, as well as premier bar grating, diamond safety grating, and round-hole safety grating systems for all types of rail applications and OEM projects.