Some years ago FOGTEC set up its own specialist rolling stock division, Rail Systems, which is based on its extensive expertise in fire protection. The wide range of customised high-pressure water mist technology solutions that FOGTEC had created for a number of different industries meant that it already had access to high-quality components and a solution-oriented team.

Rolling stock fire-protection

Today, FOGTEC, with its Rail Systems team, is one of the leading providers of fire protection solutions for rolling stock. Its service portfolio includes full service solutions, from consultancy work, the supply of components and complete systems to the installation and maintenance of fire protection systems.

Fire protection with FOGTEC Rail Systems provides:

- Reduced business interruption costs

- Greater availability of rolling stock

- Lower insurance costs

- More flexible construction

- Shorter implementation times

- Compliance with approval requirements

- Enabling of cross-border traffic

Comprehensive rolling stock fire-protection solutions

A comprehensive approach is crucial to ensure the successful implementation of all fire protection projects. The FOGTEC Rail Systems team has established itself in the rolling stock industry by providing effective and economically viable system solutions.

The range of services offered covers all important elements of fire detection and fire fighting technology, as well as additional products specifically designed for railway technology. This also covers such applications where more stringent demands need to be met (e.g. safety integrity levels).

Customised fire-protection systems

A vehicle-specific concept is produced in co-operation with the client after making a thorough assessment of the basic situation, the relevant approval issues and the advantages and disadvantages of individual solution approaches.

Feasibility is constantly evaluated even at this early stage of the project. Throughout the design phase, components can be brought together and optimised in order to reduce assembly costs to a minimum.

This is particularly relevant when it comes to the integration of fire protection components in other assembly groups and their interaction with each other. Integration into the relevant manufacturing process is carried out in close co-operation with the client.

Customised fire-detection modules and systems

Effective fire fighting is based on effective fire detection. FOGTEC offers both standardised fire detection modules and tailored systems to individual circumstances. Simple and economic monitoring solutions can be put in place as well as more challenging solutions for such applications as SIL.

System components such as smoke detectors, point and linear heat detectors, smoke aspirating systems and fire detection panels are available in a variety of technical designs.

Fire-detection system testing

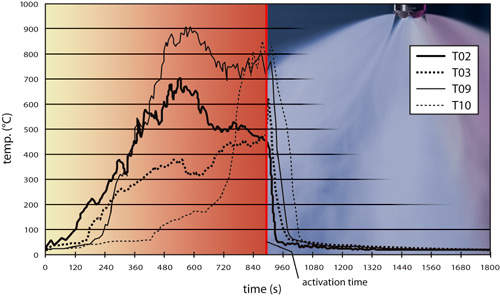

Where required as part of the approval process, real fire tests can be carried out in the FOGTEC laboratories or smoke tests can be run in the actual vehicles. These tests provide the necessary evidence for the positioning of fire detector elements in different circumstances. This work is carried out on a regular basis in close co-operation with certifiers and authorities.

Fire-fighting systems

The installation of fire fighting systems has been proved to bring about a significant reduction in direct and indirect losses. Safety levels can be greatly improved for both operators and customers. In the long term this has a positive impact on rolling stock availability and the company balance sheet.

Depending on the risk levels involved, the requirements in terms of fire protection and the installation space available, FOGTEC can offer a range of fire fighting technologies, in particular FOGTEC high-pressure water mist and nitrogen systems. To prove their suitability, most systems are subjected to full-scale fire tests in the FOGTEC laboratories.

Rolling stock applications

FOGTEC Rail Systems solutions can be found in the most different applications in a multitude of vehicle types and concepts. In most cases, the areas where these systems are installed can be categorised as follows:

- Engine rooms (diesel and electric locomotives)

- Passenger carriages (local transport trains, mainline passenger cars and sleeper cars)

- DMUs (powerpacks and generators)

- Control boxes (high, medium and low voltage)

- Hydraulic equipment (track-construction machinery and special vehicles)