Air Radiators specialises in cooling systems for diesel engine locomotives, diesel multiple units (DMU) and track maintenance equipment.

We have developed our products to work integrally with larger more efficient and complex engines, incorporating multi-pass water cooling circuits and temperature controlled fans in a noise reducing casing.

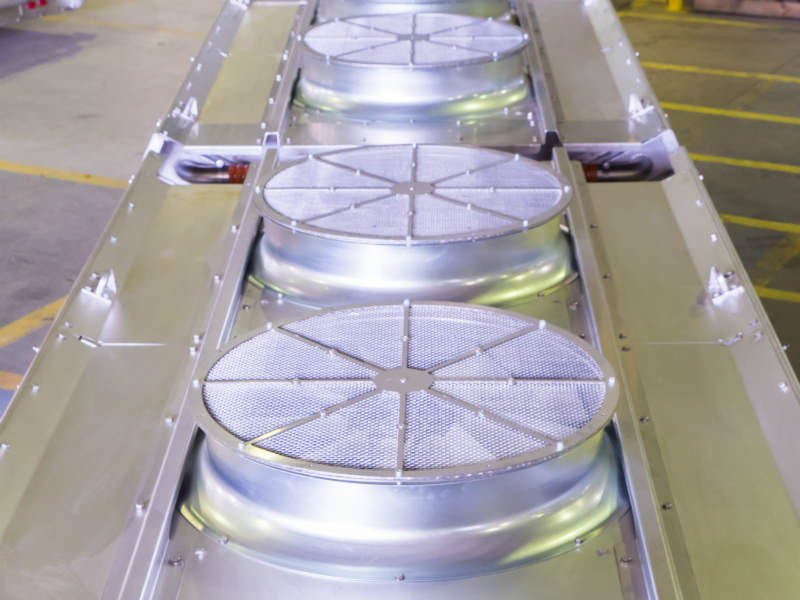

Railway heat exchanger units

To meet specific demands, Air Radiators engineers can draw from an extensive range of heat transfer matrices and materials, from aluminium to copper-based products.

Our fans range comprises aluminium and composite impellers, providing a system of standard interchangeable components and customisable solutions with advanced performance.

Most modern cooling systems comprise a hybrid package of heat transfer matrices to ensure optimum performance to cover engine, turbo and hydraulic cooling.

Flexible coolers for rail cars

New Pin Fin and Alu Fin provide unmatched versatility, featuring individual soft fixed tube elements complement our traditional technologies of welded and mechanically bonded tube to header joints.

With patents pending, Pin Fin and Alu Fin are already used for testing in rail applications.

Rolling stock cooling solutions

Our extensive fabrication and assembly facilities are staffed by fully qualified welders, operating modern plant equipment, as well as non-ferrous casting plants and high-precision machine centres.

Engineers use the latest software to ensure our products are fit for purpose and meet customer specifications, deploying computer-aided design (CAD) modelling, computational fluid dynamics (CFD), finite element analysis (FEA), as well as failure modes and effects analysis (FMEA).

Detailed 3D engineering models of all products produced by Air Radiators are generated using CAD software, while CFD software is deployed to verify fluid-flow performance by predicting and comparing flow characteristics and behaviour for different designs.

FEA is used to understand how different designs react to internally and externally generated forces. FMEA is used to improve product reliability and determine where validation and verification efforts need to be focused to mitigate risk during the product development phase.

Radiators for passenger and maintenance rolling stock

Air Radiators is currently the cooling system designer and manufacturer for the Bombardier VLocity train and East Japan Railway’s Shiki-shima luxury train suite.

The Air Radiators team have engineered and manufactured cooling systems used in cars for the Prospector and Avonlink trains in Western Australia and Newcastle’s Hunter Valley car project in New South Wales.

Working with Plasser Australia, Speno Rail Maintenance Australia, and Harsco Rail, we have also supplied fully designed and manufactured radiator packages for tamping, ballast regulators and rail grinders.

About Air Radiators

The strong engineering core underpins the quality performance of Air Radiators products. All new products created by the research and development team are tested in a full-scale wind tunnel to validate thermal performance.

CAD, FEA and CFD software allows our experienced mechanical designers to verify products before production and the extensive lean discipline manufacturing engineering team ensure designs are manufactured and built to specifications and on schedule.

With more than 40 years of experience and in-house technical capability to design and manufacture, we deliver world-class competitive products through our manufacturing centres in Australia and Thailand.