Lloyd Electric and Engineering is a leading system solutions provider of heating, ventilation and air conditioning (HVAC) for the railroad industry. With its extended capability to design, develop, manufacture and maintain highly engineered HVAC systems, Lloyd is uniquely positioned in the industry.

HVAC systems for long-distance railcars

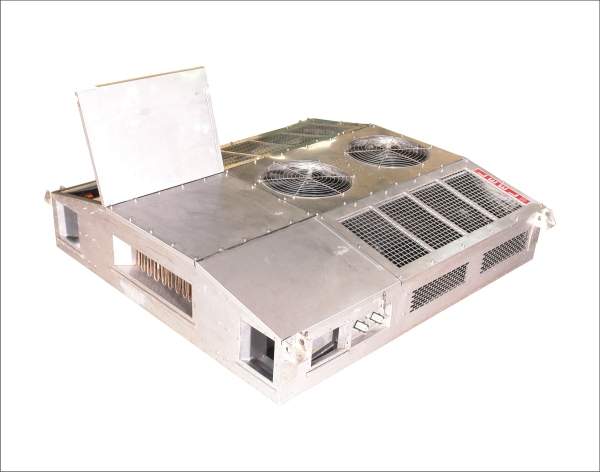

Lloyd is an expert in the design and manufacture of packaged air conditioning (AC) units for the railway industry, including AC units for long-distance passenger coaches and locomotives.

Lloyd is the original equipment manufacturer (OEM) to Indian Railways, supplying products for all rolling stock manufacturing units, as well as the first Indian Railways air conditioner company with in-house heat exchanger manufacturing facilities.

A pioneer of long-distance train HVAC systems for over 12 years, with a failure rate lower than 1%, all HVAC systems designed and tested by Lloyd comply with International Electrotechnical Commission (IEC) standards to operate in some of the most demanding high-temperature and high-humidity environments.

HVAC systems for metro railcars

To achieve the finest air conditioning in metro trains, a combination of industry knowledge and high-tech products is a necessity. Lloyd specialises in the design of energy-efficient refrigeration systems for packaged air conditioning units to be used on metro trains, which in the past has included Delhi Metro Rail Corporation (DMRC) and the Kolkata Metro project.

Lloyd HVAC systems are designed and developed to fit in with space and power restrictions, as well as comply with specific rail standards and the demands of the industry. Working in partnership with customers, from the initial concept through to the finished product, Lloyd uses the latest version of SolidWorks to turn virtual components into reality.

Lloyd HVAC systems are suitably designed for both peak summer and winter conditions to maintain passenger comfort, as well as having emergency inverters to deliver the ideal quantity of fresh air. All components used in a HVAC system are fire resistant and comply with international standards.

Ventilation systems for suburban railcars

Lloyd was the first manufacturer of roof-mounted ventilation units in India with proven design, approved by a third party, and supplied to Bharat Earth Movers Limited (BEML) for stainless-steel electrical multiple units (SS EMU).

Lloyd ventilation units are designed to supply sufficient fresh air and maintain oxygen levels inside coaches in rush hours, as well as being supplied in both restricted dimension and weight, and with ventilation units passing 3G vibration testing.

Locomotive driver’s cab HVAC units

The comfort of drivers is important to ensure the safe operation of rolling stock networks globally. Lloyd driver’s cab air conditioning systems have been designed to operate in some of the harshest conditions around the world, with temperatures up to 50°C. Units are designed with indigenous inverters for supplying 74VDC to 415VAC.

Air conditioning systems for defence applications

Lloyd has extended its capability to design, develop and manufacture defence application ACs, from 2TR to 4TR capacity with a rugged design that is suitable for cross-country terrains (-20°C to 60°C).

Lloyd’s defence application ACs comply with JSS 55555 environmental specifications, while being made from lightweight aluminium alloy with chemical agent resistive coating (CRCA). The product is eco-friendly, R134A refrigerant, part of the safety group A1 and has a zero ozone depletion potential (ODP) level.

Psychometric lab testing facility

Lloyd’s psychometric testing room facility for air conditioner performance can measure airflow, capacity, power consumption and evaluate energy efficiency ratio (EER). It is also suitable for testing unitary air conditioners.

The indoor air enthalpy method, which complies with ASHRAE standard 37 and ISO 5151, is used for capacity measurement, by determining the air enthalpies at inlet and outlet, as well as the airflow through the indoor unit. Air enthalpy properties are achieved through dry bulb and wet bulb temperature measurement, while airflow measurements are measured with a digital vane anemometer.

About Lloyd Electric and Engineering

The company’s strong track record in investing in the latest technology, state-of-the-art equipment and training its workforce on a regular basis has enabled it to become a leader in a number of markets.

Lloyd believes in high-quality products, has a keen environmental focus and goes out of its way to care for the health and safety of its employees. The company is certified for ISO 9001:2008 and IRIS Rev 2 and holds the EN 15085 certificate for welding.