Master Bond Supreme 121AOND is a toughened epoxy system for bonding and sealing applications. It is a two component, heat curing system with a thixotropic paste consistency. Supreme 121AOND not only provides excellent chemical resistance, but also offers a high glass transition temperature (Tg) of 200°C-210°C. It meets NASA low outgassing specifications as per ASTM E595 testing.

This epoxy has reliable electrical insulation properties, with a volume resistivity exceeding 1014 ohm-cm at 75°F. It possesses a high bond strength, with a tensile strength of 6,000-7,000 psi and a tensile modulus of 750,000-850,000 psi at room temperature. Supreme 121AOND retains its strength profile even at high temperatures, with a tensile modulus of 650,000-750,000 psi at 300°F. Its thermal conductivity measures 4-5 BTU•in/(ft²•hr•°F) [0.58-0.72 W/(m•K)] and it offers a wide service temperature range from -80°F to +550°F [-62°C to 288°C].

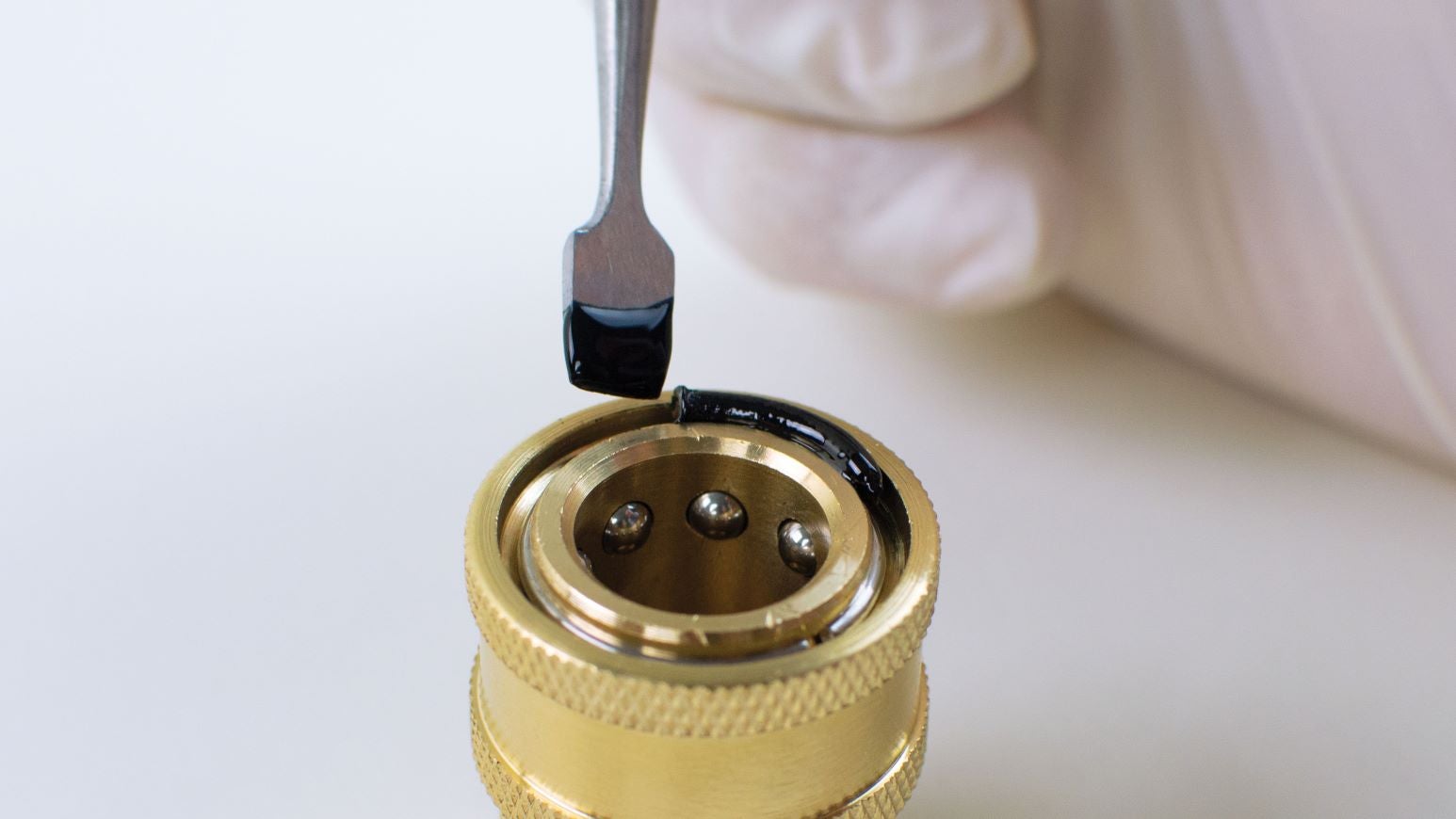

Supreme 121AOND cures at elevated temperatures and has a long working life of two to three days. A typical cure schedule is one to two hours at 200-210°F, followed by three to four hours at 250°F, and another four to six hours at 300°F. Additional post curing at 350-400°F for two to four hours will further enhance product properties. Although the cure schedule is not rapid, the key benefit conferred by this system is high structural strength even at elevated temperatures. The system bonds well to a wide variety of substrates including glass, fibres, metal, ceramics, rubbers and plastics. Part A is black, Part B is dark brown. It is available in standard packaging ranging from ½ pint kits to five gallon kits.

For more information, please visit our product page.