- Extensive noise reduction only possible through the interaction of various technologies

- Air spring systems and hydraulic springs contribute to lower traffic noise in rail transportation

- ContiTech supports federal research project for noise reduction in freight traffic

Trains should be up to 50% quieter by 2020.

"Studies have shown that real success is only possible through the combination of various methods," says Hubertus Gawinski, head of research and development at ContiTech Air Spring Systems.

"For that reason, ContiTech is continuously involved in research, because air spring systems can also contribute to successful noise reduction."

For four years, ContiTech Railway Engineering collaborated on a German Federal research project called ‘Quiet Train on a Real Track’ (L Zar G). The project was backed by the Deutsche Bahn and had the ambitious goal of reducing rail traffic noise up to 50% by 2020.

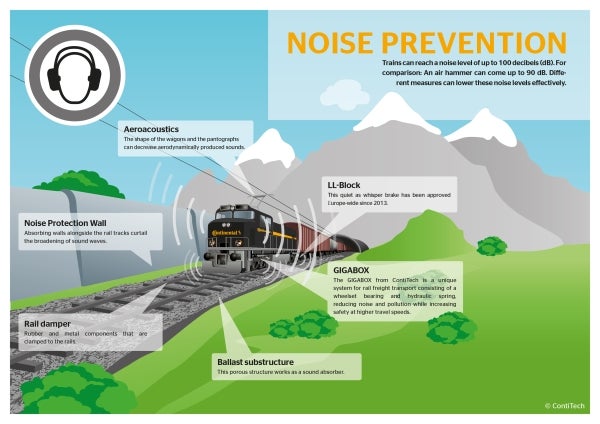

The rail company’s first act was to begin using the LL brake shoe in freight trains. Approved in 2013, the LL is a brake lining made of composite plastic. Additional technologies, such as the Gigabox, reduced noise even more.

The ContiTech spring system consists of a wheelset bearing and two hydraulic springs integrated into single-axle housing and is especially developed for rail freight transport. It does not only reduce wear to the rails, wheels and bogie, but makes for a much smoother ride. On test tracks, the system reduced noise up to 3dB.

"So far, deployment has been hampered by cost," notes Friedrich Hoppmann, head of ContiTech Railway Engineering.

"However, the cost will drop fast if the system becomes standard."

ContiTech is looking into other ways to reduce noise and will continue to work with the railway system on other research projects.

"Only when we succeed in making freight traffic on the railroads both quieter and cheaper can we assure its future," adds Gawinski.

For more information, please contact ContiTech.