Alumast is a leading designer and manufacturer of glass and fibre reinforced plastic composite columns for the railway industry.

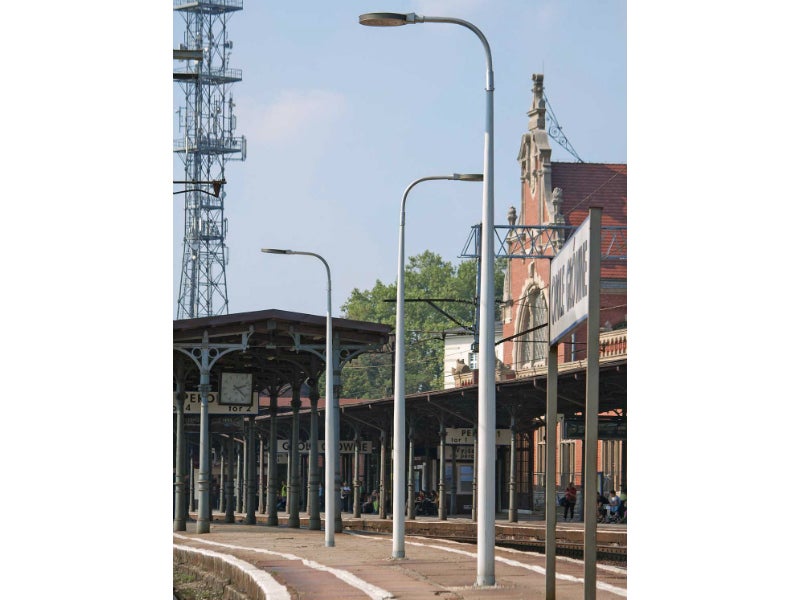

Composite lighting columns for railway stations

Our lightweight composite lighting columns have a 40-year lifespan and do not require heavy assembly equipment during installation or operation. They are a fast and low-cost solution for the railway sector.

Standard composite lighting columns BASICPOLES are produced from 3m to 12m. All of our columns are available in two variants, ground-mounted (SKPW version) or with a base plate to be mounted on the foundation (SKPF version).

An average 9m composite lighting column mounted in the ground offers cost savings during installation and transportation due to its low 59kg weight.

Alumast columns are not affected by dew points, which means that devices inside the poles will not be flooded. They are also resistant to corrosion and acid rain damage.

The multi-layered composite construction reduces vibrations from traffic and railway traction, increasing the lifespan of the discharge lamps and ignition systems. The access doors do not have any scrap value, which can reduce the amount of damage and theft.

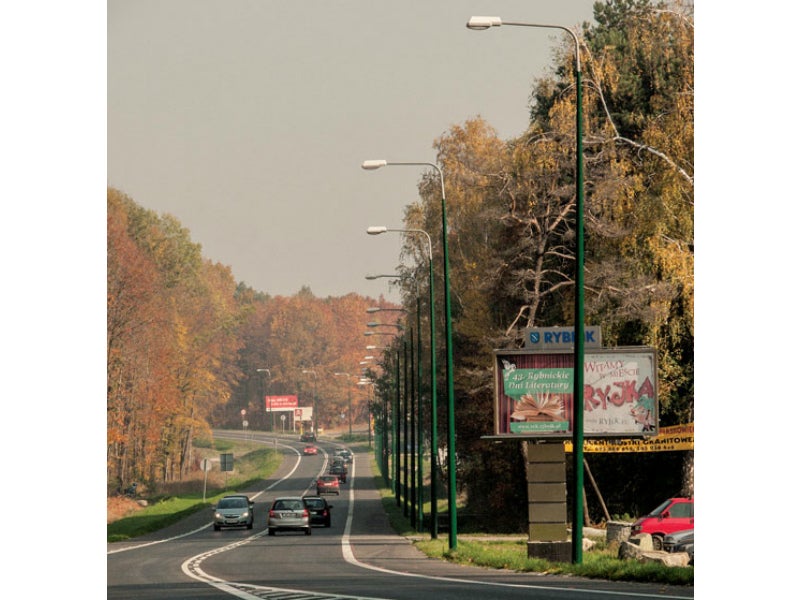

Durable composite columns for railway lighting

Composite columns are resistant to ultraviolet light, meaning that they will not be discoloured over time. They are an insulator that does not conduct electricity, so there is no need to carry out insulation resistance testing.

The smooth surface of the columns makes it easier to remove dirt, glue and even graffiti, while glass polymer composite is slow burning and resistant to damage from road materials, sea salt and high temperatures.

Our fully recyclable composite lighting columns are environmentally friendly, with low CO₂ emissions during production.

Customised glass and fibre reinforced plastic composite columns

Glass-reinforced plastic (GRP) and fibre-reinforced plastic (FRP) composite columns are an ideal solution for the railway industry.

Poland’s Railway Institute in Warsaw has positive feedback on the resistance of Alumast’s composite structures to high electrical discharges and short-circuit currents. Testing has proven the aerodynamic safety and low CO₂ emissions of our columns.

GRP and FRP composite EASYPOLE columns feature a hinged mechanism and are designed for hard-to-reach areas such as where there is no access for heavy vehicles with a platform. The columns facilitate assembly and disassembly of lighting, as well as replacement of the light source. Columns range from 4m to 9m and have low transport costs.

Columns can be manufactured according to customer specifications, as well as reinforced for adverse operations conditions.

We are constantly looking for new composite applications to ensure that the material properties are used widely across the railway industry.

About Alumast

Alumast SA was established in 2000 in Wodzisław Śląski, Poland.

Our production technology has been developed by the Central Mining Institute and Silesian University of Technology in Poland.

We have more than 20 years of experience, close cooperation with research centres, as well as our own research facilities and strong partnerships with experienced design industry companies.