Amest specialises in the development, construction, installation and service of monitoring stations, observation measures and measuring machines for production control of component dimensions and shapes.

Amest also concentrates on non-destructive flaw detection identification of mechanical properties and defects of material, as well as weight control in mass production of components, including their labelling and sorting according to chosen parameters.

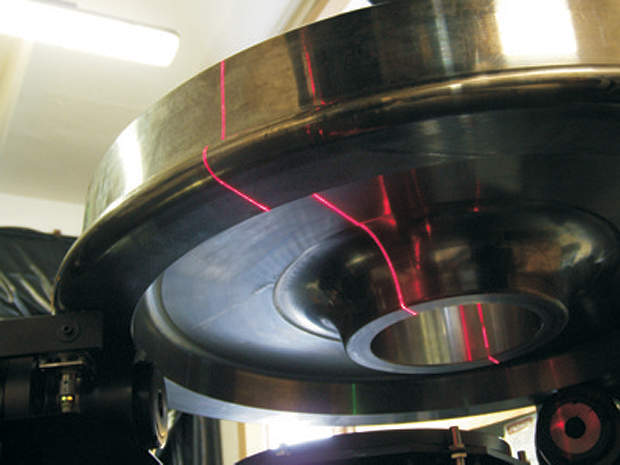

Automatic measuring station for railway wheels

The KS-528 (KS-570) is an automatic measuring station for geometry control of railway wheels. The control device is used to make a complete check on wheels manufactured in non-stop three-shift serial production.

The station is easy to set for all types and dimensions of wheels manufactured in the client’s factory, including everything from small tram wheels to huge locomotive wheels. It’s able to measure all geometric parameters such as riding and disc profiles, diameters, axial lengths, run-outs, circularity, radiuses and many others.

Automatic measuring station for railway axles

Amest’s KS-551 automatic measuring station for geometry control of railway axles offers a complete check of axle geometry parameters including diameters, axial lengths, cylindricity, circularity, axial lengths and radiuses.

The station’s measurement accuracy of ±0,5µm fulfils all customer requirements for high performance.

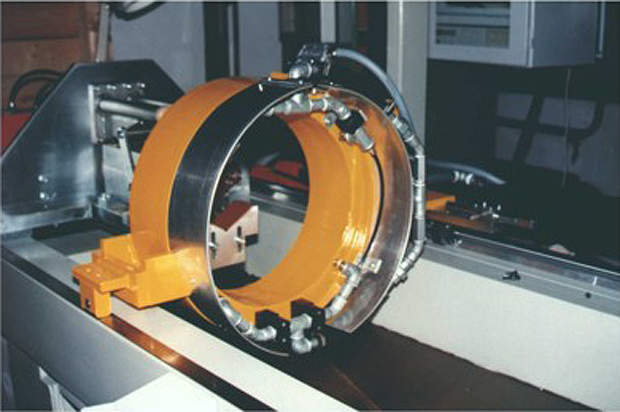

Measuring station wheel hub diameter and disc bores

The KS-568 device successively measures hub holes in three sections, or in a selected number of sections. Measuring utilises a new principle of dynamic measuring heads (DMH) that allows the check of polar circularity in all sections, as well as the positions of centres, concave and convex profile, and the taper ratio. This measuring method ensures a complex check of the wheel before pressing the wheel set, or complex dimensional report prior to dispatch.

Automatic measurement of precision axle ends

Amest allows measurement in an unusual range of dimensions and within a short time cycle with high accuracy. The separated construction of the loading point minimises the effect of external handling on the gauging part of the device. The control device is able to measure outer/inner diameters, outer/inner threads, concentricity, etc.

Non-destructive checking of railway wheels and axles

Amest is also a producer of control devices for magnetic and ultrasound control of railway wheels and axles, with 20 years experience in the railway market.