bvSys’s automatic railway inspection systems combine precise defect detection with high processing speed. There are no limits on scheduled rail traffic, these systems provide regular and economic track inspection. Damages are discovered very early, making it possible to substantially extend the lifecycle of tracks through preventative measures.

All systems feature:

- High inspection speed

- High inspection accuracy

- Real-time processing

- Precise detection of even the smallest fault structures

- Comparison of individual images with track data accurate to a meter

- Easy and intuitive operation

All systems can be installed individually or in combination of any type of carrier vehicle. The data gathered from all connected inspection systems is digitally stored in the central data acquisition unit (CDA-Unit). In the course of the recording process and upon completion of the trip, the inspection results can be analysed and documented summarily or separated by the system.

RailCheck: surface track safety inspections at high speed

The RailCheck system is designed for automatic detection of visible anomalies on the surface of the rail, missing fastening elements, cracked or damaged concrete sleepers and measuring the ballast profile. High-performance line scan cameras and laser distance sensors, which are installed vertically above the tracks, observe both rails, designated areas of the sleepers and the ballast.

- Broken Rails

- rail breaks

- insulated rail joints

- Running Edge Defects

- chunking

- head check (final stage)

- Travelling Surface Defects

- chunking

- imprint

- wheel burn

- corrugation

- Missing Fasteners

- Sleepers (concrete sleepers)

- safety relevant cracks

- missing material

- Ballast Profile

- overfilling

- underfilling

As an automatic inspection system RailCheck inspects the entire area of the track structure for safety-relevant defects at high speed of more than 200 km/h. It produces a track condition protocol as a result to generate an objective status of the inspected track for the user with high quality and safety in the shortest time. The vertically angled track lighting guarantees optimum inspection results even under wet conditions.

HeadCheck: running edge damage detection

The HeadCheck system is an autonomous structure which allows automatic detection of head checks at the rail running edge at a very early stage. The rails are scanned with a high resolution digital line scan camera and automatically checked for indications of head checks at various stages of formation:

- Defect Level 3

Weakly pronounced cracks on the running edge, rail age, siding loading, damages and fractures in neighbouring sections are to be included in the evaluation. - Defect Level 2

Pronounced cracks on the running edge without ruptures, rail age, siding loading, damages and fractures in neighboring sections are to be included in the evaluation. - Defect Level 1

Pronounced cracks with numerous ruptures

With a very high resolution, the cameras record every detail of the surface so that even the smallest inconsistencies can be detected.

JointCheck: inspection of the connections

JointCheck is an automatic inspection system which inspects safety fish plates of rail connections at high speed. JointCheck inspects missing bolts, missing nuts or crack formations in the fish plates and enters the results into a track state protocol so that a high quality objective survey of the track is available at short notice.

Controlled by a wheel encoder which is mounted to an axle, the lateral rail web is recorded with digital line scan cameras from both sides. Every pulse initiates a photograph of a line with a resolution of 0.09 mm (resolution per pixel along the line). Every millimeter a single line is recorded and all individual lines are composed to an endless picture.

Using the latest image processing technologies, JointCheck ensures that the inspection of the rail connections becomes quicker, safer and more reliable.

CrackCheck: ballastless track and concrete sleeper inspection

The digital recording system CrackCheck serves to automatically inspect the condition of ballastless track and concrete sleepers. Finest crack structures are detected by the system and the corresponding pictures are stored in a database.

At high speed the system detects

- cracked or damaged concrete sleepers

- cracked or damaged concrete track (ballastless track)

ProfileCheck: rail head measuring

ProfileCheck is a high-precision optical measurement system for the contactless inspection of vertical rail sections and cross-sections of railway tracks at a speed up to 200 km/h. The system is used for the following measuring tasks:

- Rail head cross-section

- rail type identification

- complete measurement of the rail profile

- gauge

- equivalent conicity

- Rail head vertical section

- corrugation

- short waves from 30mm to 100mm

- short waves from 100mm to 300mm

- short waves from 300mm to 1000mm

- Car body compensation

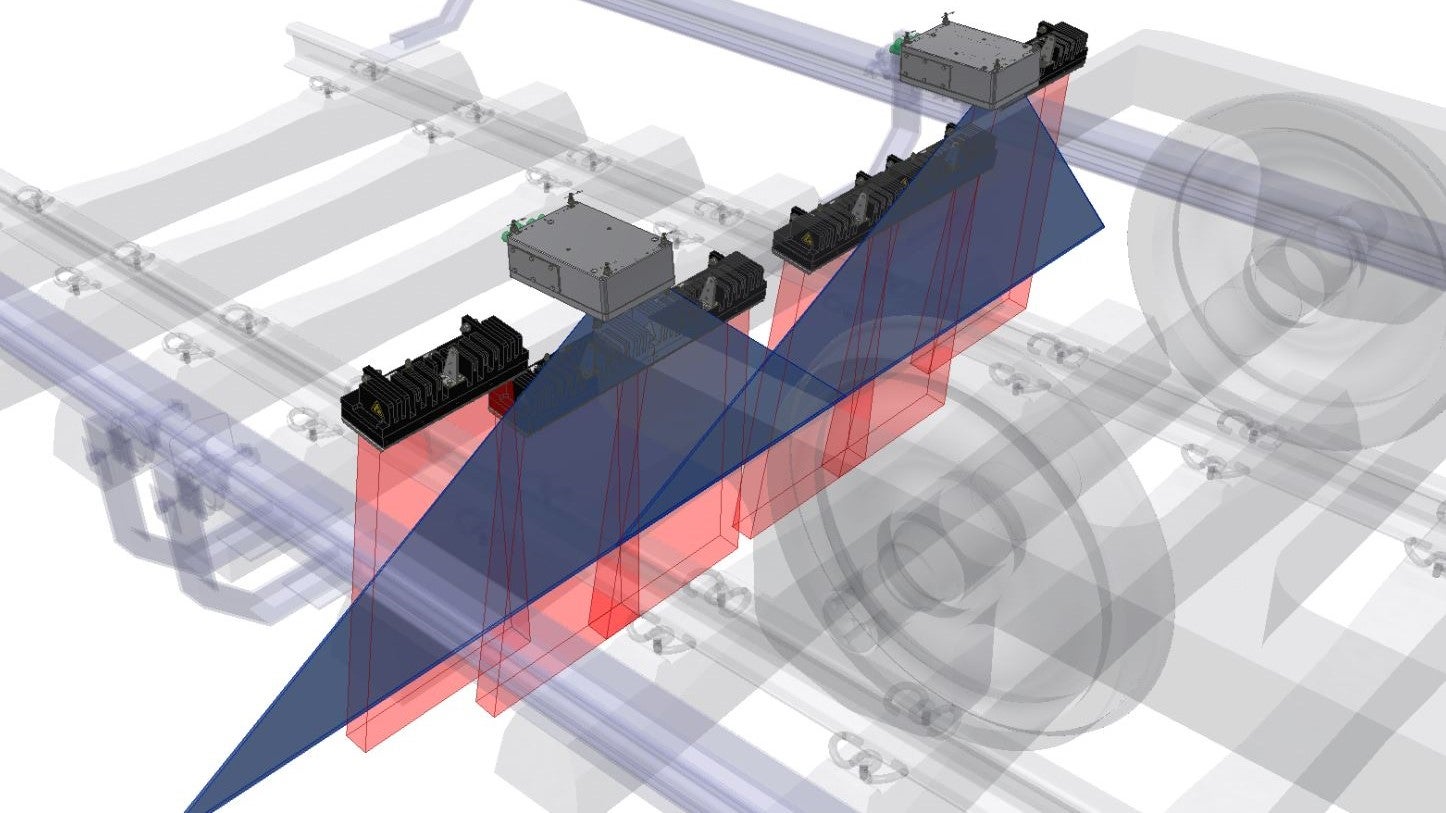

The detection of rail damages the running edge and rail surface enables reprofiling of the rails at an early stage, which increases the life time of the rail considerably. The system is based on the measuring principle of contactless laser triangulation. The cross section measuring system is used for the precise measurement of the rail profile as well as the gauge.

During the inspection run, the gauge, the amplitudes of the corrugation and waves as well as the rail head cross section are displayed online. In the fault protocol that is created, faulty track areas are identified to the exact meter position by means of the way assignment and way synchronisation system.

WireCheck: efficient and precise inspection of contact wires

WireCheck is an automatic measurement system, which determines the thickness or the remaining height of one or more parallel contact wires at high speed. Two high-speed linear CCD cameras combined with infrared laser light illumination subsequently scan the contact wires from opposite directions.

Main features of the WireCheck system are:

- Image acquisition of the contact wire from opposite sides

- Contactless measurement of the height and position of contact wire

- Contactless measurement of the contact surface width and the visible wire diameter by image processing

- Calculation of the remaining height by considering the wire diameter

CatenaryCheck: fast, safe and reliable overhead cable inspection

CatenaryCheck is an automatic inspection system, which inspects the catenary and catenary cross span at high speed.

- Automatic detection of defects by image processing: loose or missing screws, split cables, damaged components

- Image recording of droppers, messenger wire, contact wire, shunt straps and clamps

- Contactless image acquisition of the catenary from opposite sides

- Continuously record images of the entire catenary

- Contactless image acquisition of the catenary cross span from opposite sides

- Optimal image quality is provided for the subsequent processing steps, which makes visible even the finest details of the catenary cross section

- Contactless determining the position of the contact wires in real time (laser triangulation)

Railway line occupancy is continually increasing, so it is essential that the user knows the status of the inspected railway line in the shortest time. With the aid of pioneering sensors and the most modern image processing technologies CatenaryCheck ensures that the contact wire inspection is fast, safe and reliable.

VegetationCheck: controlling plant growth on tracks

VegetationCheck is an automatic inspection system, which inspects the entire area of the rail bed structure, the periphery and track area at speeds of over 100km/h.

Automatically fixing the degree of Vegetation:

- Classifying the degree of vegetation into three areas: rail grid, margin, and route

- Real time vegetation recognition

- Connecting vegetation analysis direct to the herbicide spraying device

The system produces a rail condition protocol as a result, which presents an objective status of the inspected track section for the user with high quality and safety in the shortest time. Using the latest image processing technologies VegetationCheck ensures that the track structure inspection is faster, safer and more reliable.

Central Data Acquisition Unit (CDA)

The Central Data Acquisition Unit is used for controlling the recording and visualisation of the measuring data of all inspection systems connected to the CDA-Unit.

The workstation equipped with high-resolution monitors serves for the process visualisation and for the online result presentation of the connected systems to monitor the entire inspection run.

Even in case of extensive evaluation data at high speed, fast online data processing can be achieved by decentralised computing power in conjunction with extensive data capacity of an external database server.

The kilometer and recording control in the inspection vehicle allows a direct control of the journey progress, as well as the setting of position markers and comments for particular inspection run sequences.

During the ongoing inspection run the current system status is documented with inspection parameters as well as location and chainage.

The Way-Assignment system creates the corresponding position information during the inspection run. Defects that require immediate action can raise an alarm which can be propagated online to an operator in charge.

The Central Data Acquisition Unit system is implemented as an open system, which can also be subsequently extended by further modules.