Cordel offers an innovative solution that efficiently and safely monitors rail infrastructure.

Cordel combines scalable Cloud-based data analytics and powerful deep machine learning in a cost-effective platform that automates the processing of rail intelligence data. It provides deeper insights using data captured by in-service trains and low cost fixed sensors.

Technology-driven railway inspections

The automated Cordel data platform offers faster, more accurate results, which enable:

- Improved rail worker and rail customer safety

- Increases to network revenue

- Reduced cost of inspections

- Enhanced data-driven decision-making

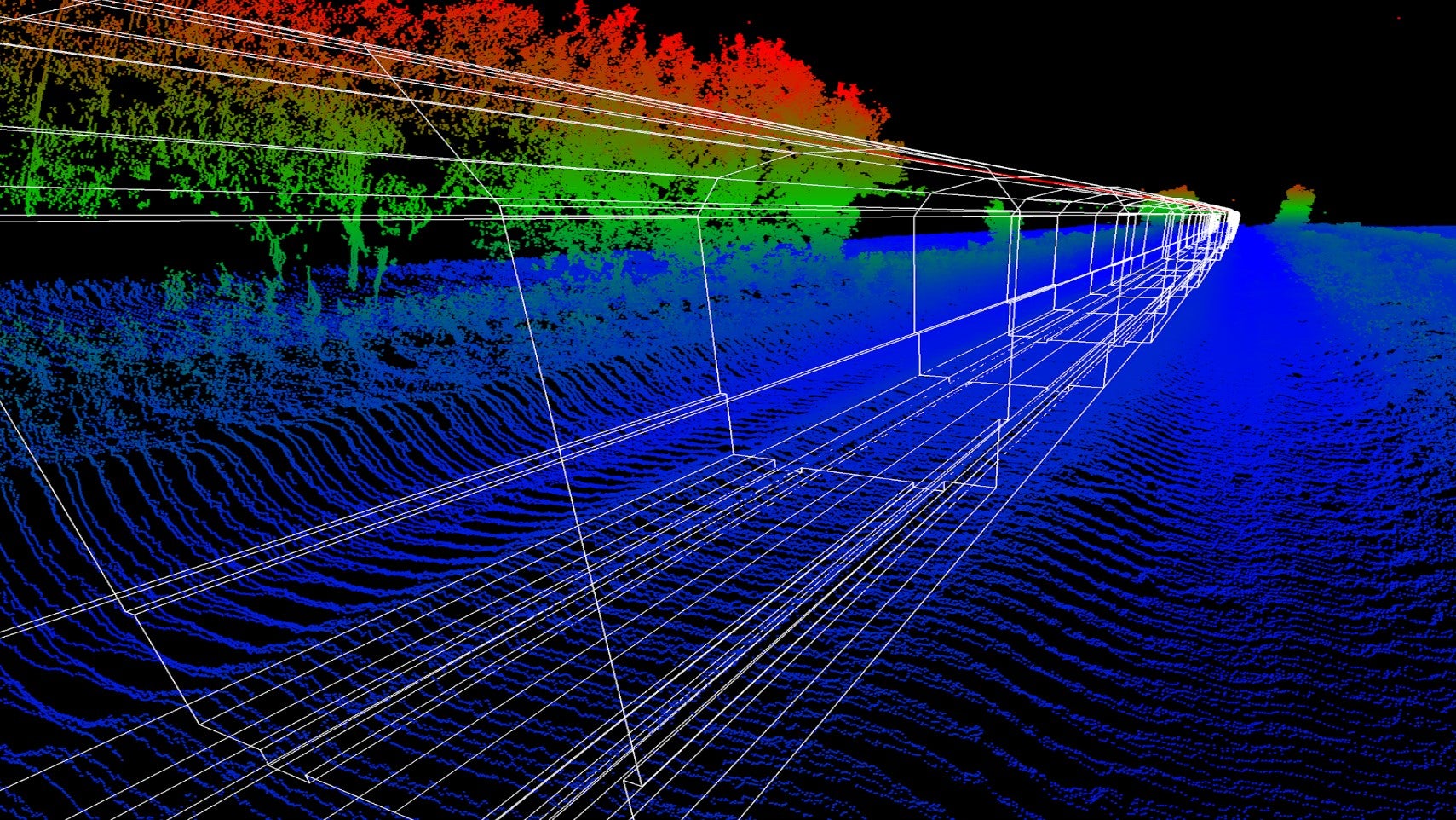

The platform improves the network’s ability to inspect and monitor assets by taking advantage of modern technologies such as NextCore LiDAR, GPS positioning, and artificial intelligence (AI). This enables networks to implement more resilient timetables and maintenance programmes.

The primary components of the platform ensure bespoke deployments to solve specific railway engineering problems.

Railway asset inspections

Cordel’s low-cost, miniaturised hardware systems can be installed on board in-service trains, diagnostic services, hi-rails and stationary installations (gantries and CCTV).

Utilising LiDAR, high-resolution imagery, tactical grade GNSS (GPS) positioning data and inertial navigation systems (INS), our clients can combine these data sources to capture network condition regularly and accurately while creating a dynamic digital twin of the rail network.

Automated inspection data analysis

The Cordel solution features a powerful machine learning platform that automates the process of fusing data, detecting assets, rating asset conditions, measuring change and finding anomalies within the network.

Through the implementation of thorough engineering-grade quality control mechanisms and supervised workflows, networks rely on the platform to manage and inspect safety-critical systems, as well as increase resiliency.

Advanced rail network inspection reports

Utilising scalable Cloud and edge-based computational systems, our platform offers high-quality control, security and system integrity with optimised system and network resources.

Its connectivity to industry-standard Enterprise Asset Management (EAM) and Geographical Information Systems (GIS) software via APIs enables complete network visibility without additional software platforms.

The platform is adaptable to all rail environments, including public transport corridors, freight lines and mining railways. By focusing on client outcomes, it delivers solutions based on existing software systems, processes, network types and inspection regimes.

Machine learning for the railway industry

Cordel’s machine learning railway technology automatically creates context and structure to remote sensing data such as imagery and video, LiDAR, GPS and trajectory data.

The platform can also automate inspections that can be unreliable, expensive and dangerous when conducted manually.

System efficiencies are delivered through the triaging or shortlisting of anomalies and automatically reporting by exception. Rather than removing the need for engineering expertise, it allows inspectors to spend more time addressing issues instead of locating them.

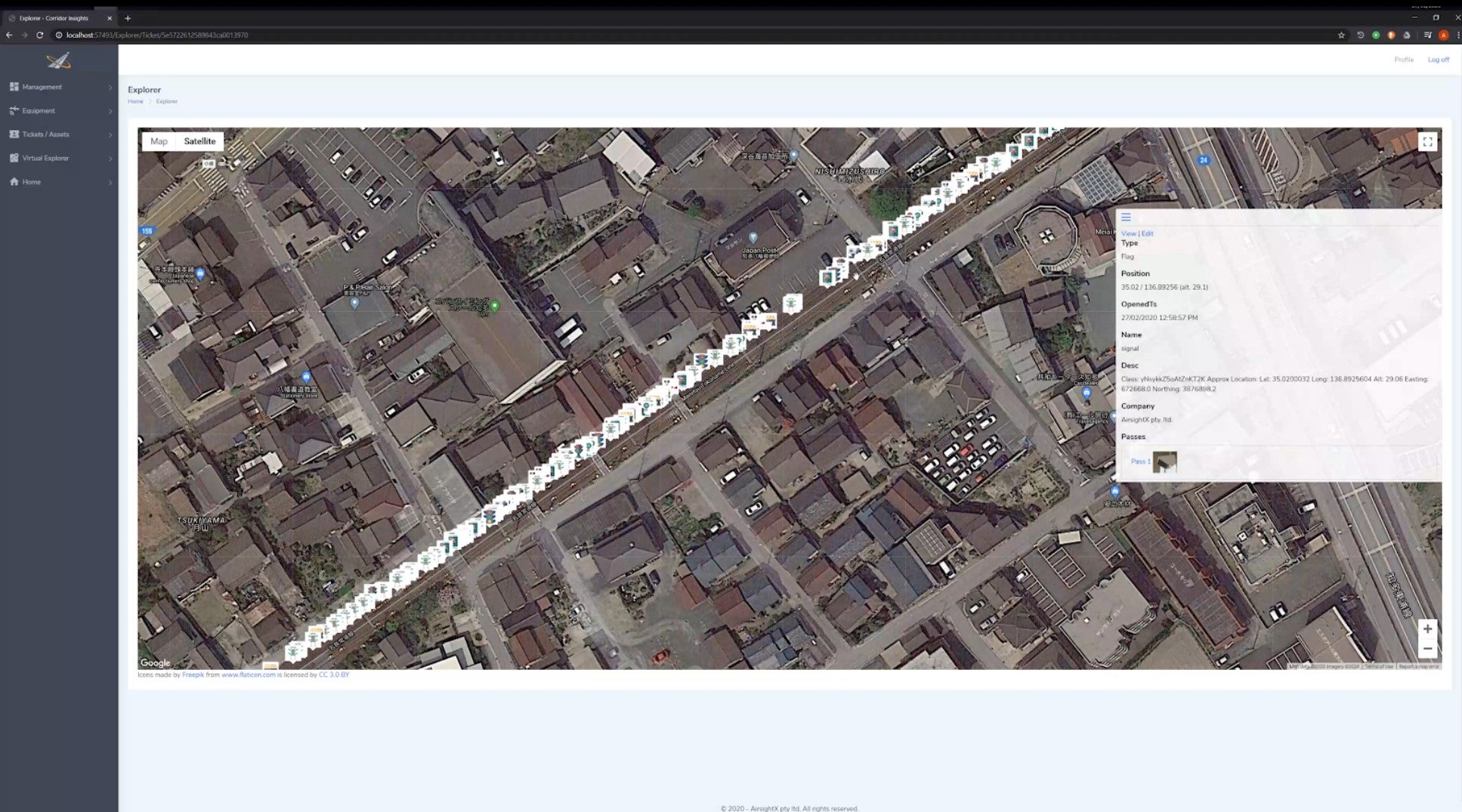

Inspection management software

The Cordel Cloud-based inspection management system allows railway inspectors and management to review inspection data, as well as add further details and inspection criteria to the automated outpost from the AI.

Allowing users to search, review and refine inspections, the solution improves efficiency, effectiveness and accuracy while decreasing the costs and risks associated with working inside rail corridors.

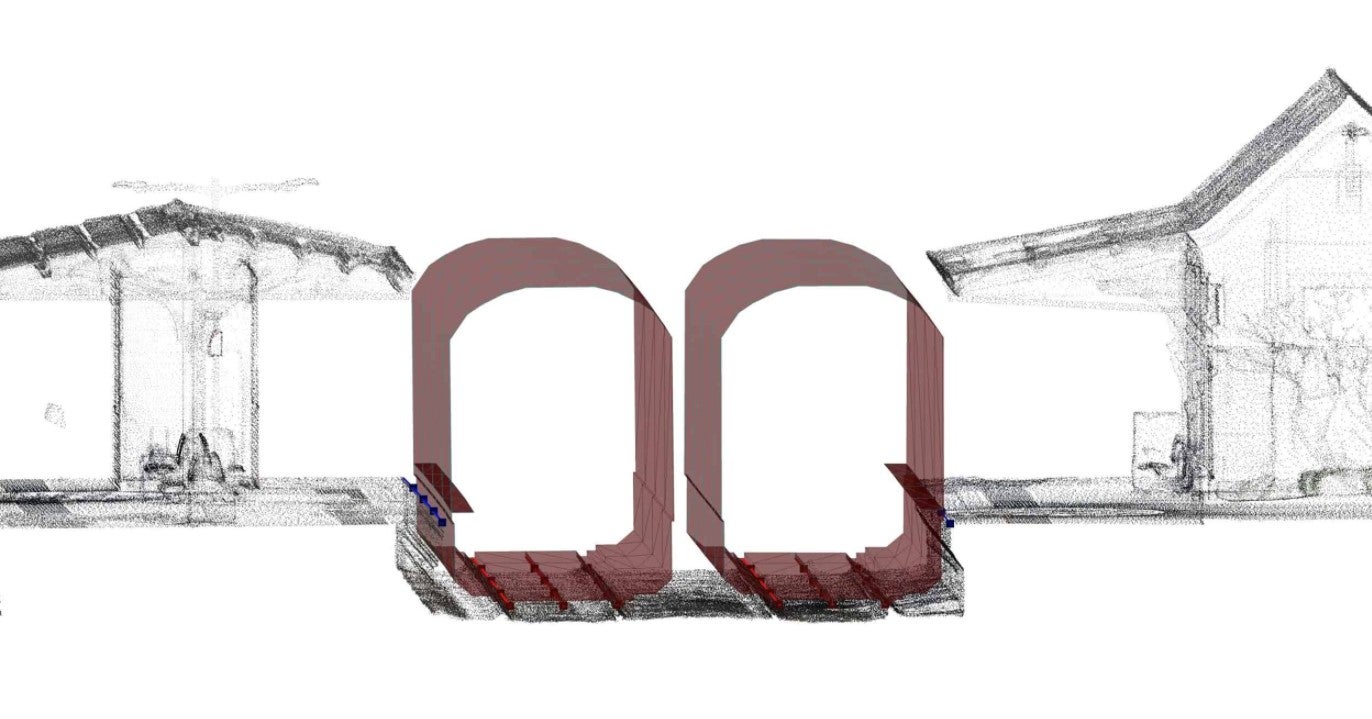

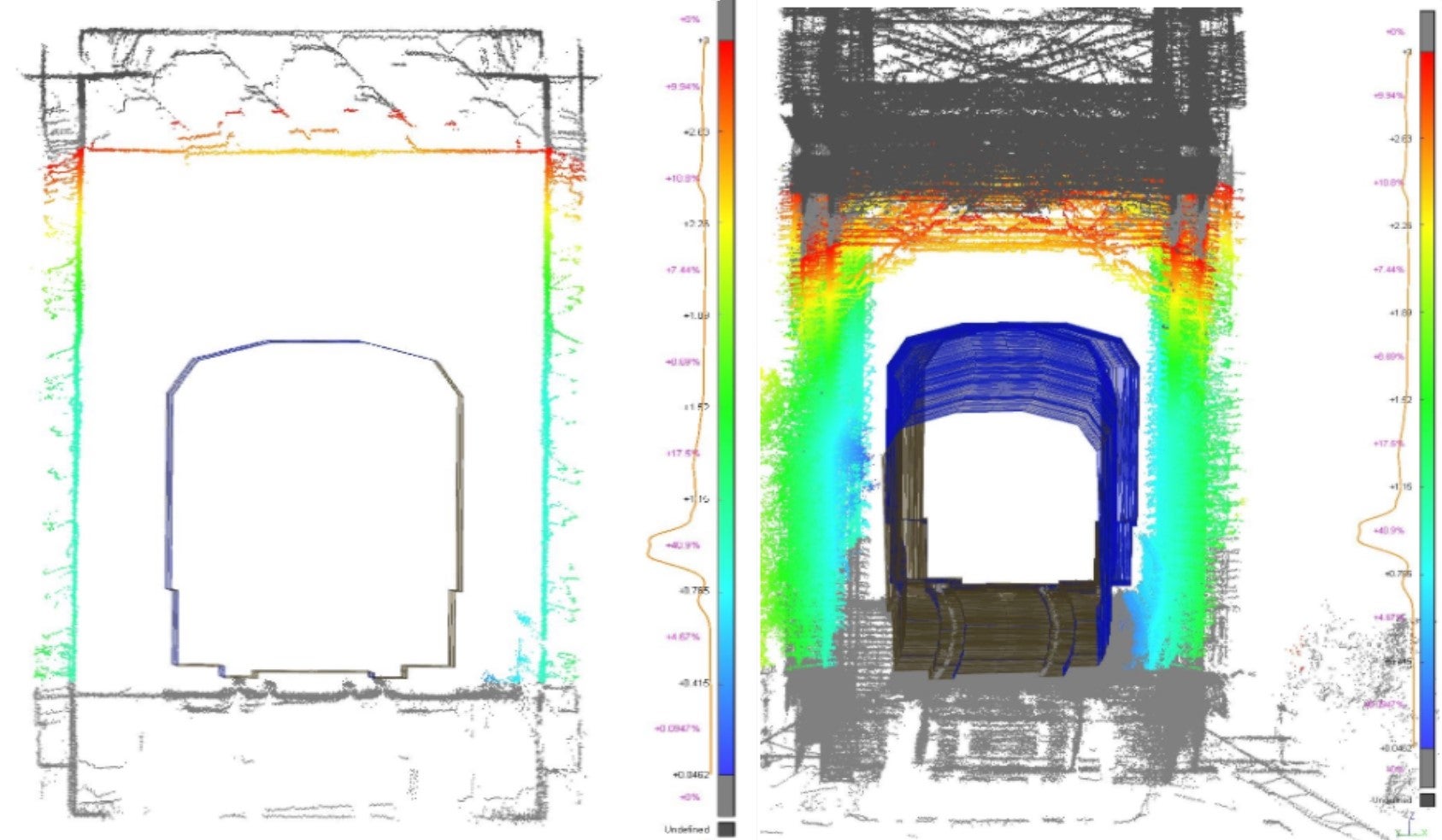

Gauging and infringements using AI and LiDAR

All railways need to maintain adequate clearance between the vehicle and adjacent structures while retaining sufficient passing clearance between the train and other vehicles on adjacent tracks.

Cordel allows networks to automatically process thousands of kilometres of LiDAR data for railway structure gauging and exceedance reporting using the automated processing engine.

Ballast profiling using machine learning

Optimised inspection and management of ballast profiles can significantly impact rail maintenance costs.

Cordel’s LiDAR scanning system provides a detailed analysis of the ballast profile, detects and reports changes before they subsequently affect operations.

Cordel can automatically identify early indicators and reports on:

- Mud spots and bog holes

- Changes to the ballast shape and depth

- Colourisation changes due to spillage caused by ballast aggregate

- Drainage anomalies

By detecting early changes in the ballast profile, engineers can better target their efforts to these critical areas. This reduces the severity of issues and improves the railway network performance.

Automatic track patrols from in-service trains

Track patrols help to detect issues before they can become problematic and in many cases, are a statutory requirement by authorities to provide a safe railway.

The Dashscan™ system enables Cordel clients to achieve more in-depth insights into network health and optimise maintenance activities by identifying issues earlier in the maintenance cycle.

By using machine learning to process captured imagery from in-service trains, networks are monitored for defects without the need for track possessions, reduced diagnostic train services or Hi-Rail inspections.

Track patrols using the Dashscan™ can prepare priority-based asset maintenance plans and renewal programmes, as well as monitor tracks, networks and gradual track variations.

Level crossing inspection and sighting distances

Level crossings create risk for rail and road passengers when not adequately assessed.

The Cordel Pointscan™ system creates an accurate survey of level crossings for users to better understand inherent risks. The point cloud created through the platform can help ensure that all possible viewpoints are assessed for visual impairment.

This survey is achieved while mounted on in-service vehicles travelling at line speed rather than being conducted by on-site survey teams, resulting in significant cost savings and increased inspection frequency.

When paired with the Dashscan™, data form level crossings can identify potholes, cracks, rubbing marks, rust spots on rail webs, and flangeway clearances.

Vegetation management using visual data

Cordel’s automated vegetation management feature uses LiDAR and imagery to automatically assess the static envelope of the train’s path. By identifying infringements and evaluating the encroachment, vegetation removal is managed more strategically and effectively.

Once repeated scanning occurs in the network, areas of significant vegetation growth and risk can be automatically identified and maintained, allowing for early preventative interventions.

In doing so, Cordel clients can reduce rail slippage, improve rail access for future vegetation removal and eliminate stoppages due to blockages.