I-moss produces, installs and maintains customised railway measurement systems that provide continuous monitoring of vehicle and track conditions, providing early detection of faults and signs of wear.

Monitoring solutions for rolling stock and track infrastructure

The monitoring systems are built around a modular architecture, allowing for data acquisition from various sensor types used to monitor different aspects of the rail infrastructure. Acquired data is analysed using advanced techniques and signal processing algorithms to create asset condition monitoring reports.

Final reports are provided in a web-optimised format and are integrated into maintenance management programmes to trigger appropriate maintenance actions.

Cost-effective measurement and monitoring systems are suitable for large and small networks. They allow for condition-based maintenance and significant reductions in the maintenance costs.

Wheel flat detection and Out-of-Roundness Monitoring

The Wheel flat and Out-of-Roundness Monitoring (WORM) system is used for tracking wheel conditions, as well as detecting flats and ovalisation on light and heavy rail vehicles. It also identifies vehicles and registers their speeds.

The WORM system is used in an improved fleet maintenance management approach, reducing repair costs and maximising vehicle availability. Immediate alerts of wheel irregularities allow for action to be taken before damage occurs.

Installation of a WORM system also leads to improved comfort and safety for passengers. It is essential for infrastructure managers to monitor the state of the rolling stock across their service and what wear is being caused.

Condition-based maintenance for train wheels

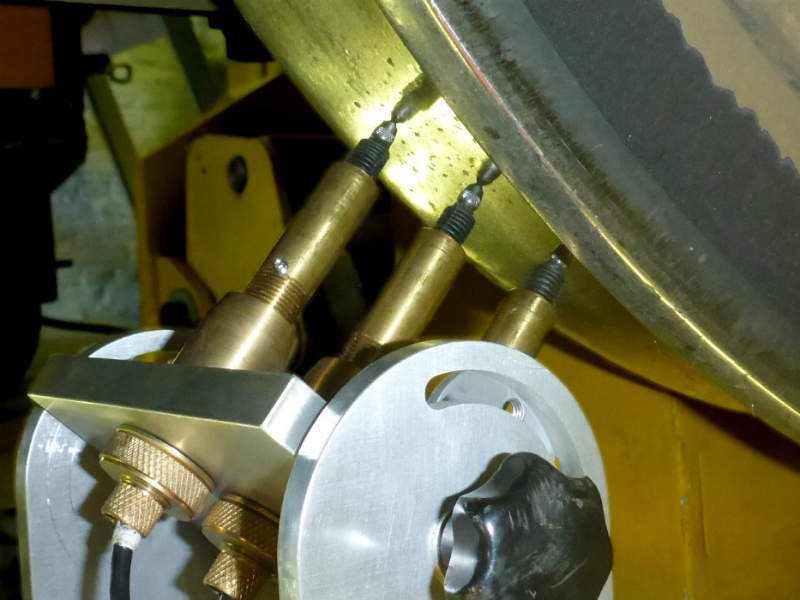

The I-moss WORM uses robust track-mounted sensors to measure vibrations caused by the wheel-to-rail contact. The system installation has been developed to take up a small area of the track with a quick set up time on newly built and existing track.

Acquired train vibration data is filtered and processed to identify irregularities for each passing vehicle. The track-side electronics contains a powerful computer for quick local analysis of the passing vehicles. Immediate alerts are generated and detailed results are stored in a Cloud database for further data analysis, such as trends in each vehicle or fleet-wide analysis.

The system can be coupled with other track-based monitoring systems or with vehicle identification systems such as radio-frequency identification (RFID).

Rail and wheel roughness and corrugation measurement

I-moss’s Rail Surface Analyser (RSA) assesses the condition of the rail using a trolley system, measuring the vertical variation of the railhead contact surface, as specified in ISO 3095:2013, EN 13231-3:2012 and EN 15610:2009 standards.

RSA’s main applications include rail roughness and corrugation measurements, and testing of the grinding quality in the support of noise level predictions. It features three-point contact measurement transducers, allowing for continuous measurement of the rail track. It can be used on track gauges from 1,000mm to 1,668mm, and on flat-bottomed (Vignol) or grooved rail.

RSA is a piece of lightweight track equipment and can be installed and removed from the track in a matter of seconds. It can be applied with minimal interruption to services, taking up little track time.

Data processing software provides report-ready graphics, including vertical displacement levels along the rail, roughness spectra in 1/3 octave bands and colour maps.

The Wheel Surface Analyser (WSA) is used to measure wheel circumference irregularities. It is primarily used for measuring wheel roughness, diameter, and shape, as well as noise level predictions.

This webpage is developed with the support of: