Infrastructure Measurement Solutions (IMS) designs vibration monitoring systems that locate and record common faults on railway tracks.

Defect sensors for rail tracks

The BumpBox is a ruggedised computer designed for challenging rail environments.

The Linux-based unit comprises acceleration and gyroscope sensing transducers with eight transducer input channels. The BumpBox features GPS, GPRS and Wi-Fi capabilities.

An on-board disk captures all recorded track data in either standalone or automated distribution modes. Data can be sent via email, mobile or Cloud platform for secure, real-time customer access.

An external monitor, keyboard and mouse can be used to the unit if Wi-Fi or 3G isn’t available.

BumpBox features a user-friendly software interface with connectivity to the unit across Wi-Fi using a laptop, so end-users can view stored event data or perform real-time, continuous, on-board monitoring.

Data solutions for railway conditions

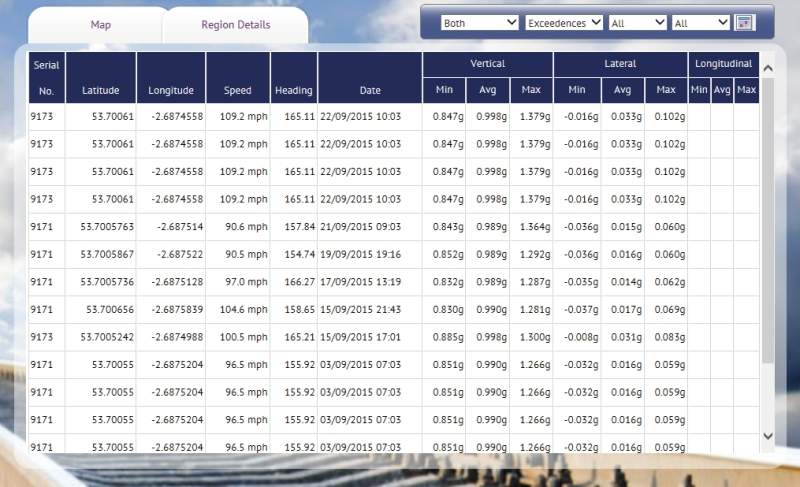

IMS’s web-based software application for data presentation, using charts, graphs and geographical data is customisable to meet the specifications of the client. Remote diagnostics enables end-users to alter exceedence levels and ensure the unit is functioning correctly.

Multiple data sets / event data from the same or different vehicles crossing the same track can be compared against supply defect validation and/or defect growth monitoring, in addition to determine trending techniques.

Data is also provided on infrastructure condition to ensure maintain optimal track quality and condition, as well as enabling advanced predictive maintenance planning.

The internal software is adaptable to fulfil the following related standards:

- BS EN 2009;12299: Ride comfort for passengers

- ISO 2631 Mechanical Vibration and Shock: Human exposure to the whole body vibrations

- UIC513: Passenger comfort in relation to vibrations in Rail Vehicles

On-board track measurements

The BumpBox records measurements such as distance, gyroscope heading rate, lateral, longitudinal and vertical accelerations, travel direction, speed, time and date. Each data recording is identified with a unique unit / train identification number and exceedence levels.

Solid state relay outputs enable interconnection (with isolation) into the on-board vehicle logging systems if necessary.

The on-board transducers are currently used with specialised signature algorithms to identify uncomfortable track areas and causes of significant vertical exceedence levels. The unit can also be used to identify vehicle vibrations caused by deteriorating suspension.

Data features of the BumpBox include:

- Bar graph arrays detailing event occurrences, which change colour as defects grow in size

- Six-second updates on geographical location of all units

- Web-based event mapping dashboard against GPS co-ordinates

Vibration system architecture of railways

Utilising modern embedded computing technology, the Bump Box recognises and records common track faults by measuring the shock and vibration characteristics generated in the rail carriage operating over the defect.

The system can be configured to activate on particular pre-defined shock levels and can also log information, including pre-events and post-events. Multiple events can be recorded and stored in the BumpBox covering multiple test runs for future analysis.

The information is stored graphically and can be presented according to the client’s particular requirements.

Previous railway projects

Since developing the concept, IMS has installed BumpBox on multiple trains in the UK. These include rail units by Virgin Trains, East Midlands Trains, Siemens and Chiltern Railways.