INNDES is an engineering and manufacturing company that develops machinery and equipment for heavy-duty rail maintenance depots.

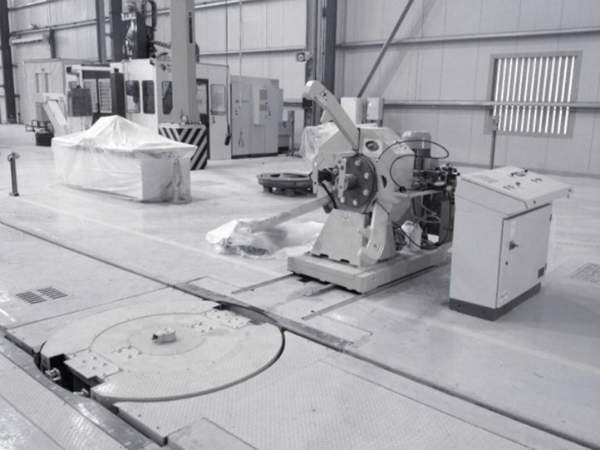

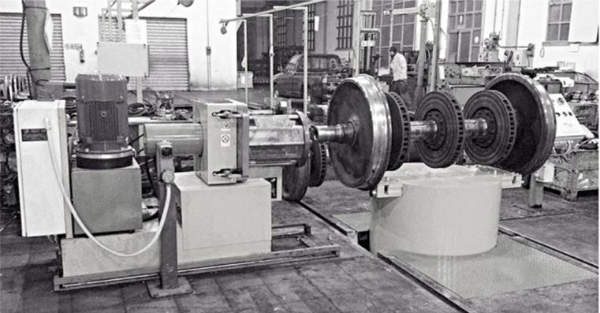

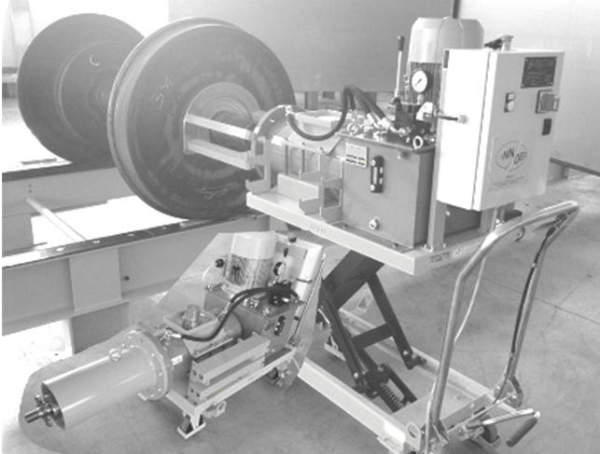

The company specialises in the design and construction of bogie, wheelset and bearing maintenance equipment.

Heavy-duty railway maintenance equipment

The range of products covers most requirements of a heavy-duty maintenance workshop and includes the bearing universal press (BUP) for assembly / disassembly, buffer handling device (BHD) and wheel puller press (WPP). Other equipment available comprises the spring test machine (STM), mobile bogie press (MBP) for assembly / disassembly, rollover stand (ROS) for engine and UHE bogie frame rotators.

INNDES offers a range of services for the railway industry that includes engineering and consultancy for heavy maintenance depots; technical design, service and manufacture; as well as monitor maintenance and spare parts management.

Maintenance operations and equipment for the railway industry

Through years of technical expertise in railway workshops and practical experience, INNDES holds a leading position in the sector. The company cooperates with prominent Italian maintenance workshops, in addition to general contractors and railway operators worldwide to expand the business.

INNDES combines technical expertise of railway industry standards with high-quality engineering.

Railway maintenance depots require specialist knowledge and are often subject to changes. The company has developed a wide range of manufacturing expertise in the sector and continues working to improve its understanding of market requirements to find the optimal solution for any customer requirement.

About INNDES

Established in 2006, INNDES is a small company headquartered in northern Italy. All of the company’s plants and equipment is delivered from its manufacturing depot in Vicenza.

The company exhibits its product range at InnoTrans in Berlin, Germany, offering a platform for networking opportunities and showcasing its latest solutions.

INNDES aims to reach a leading position in the area of design, manufacture and service of equipment for railway maintenance and general mechanical workshops. The company has a competitive advantage due to its adaptable structure that allows efficiency and cost savings in various business areas.

The company’s quality management plan provides the general background to achieve, maintain and improve the competitiveness in the industrial sector of railway maintenance depots. It helps coordinate long-term goals through the implementation of short-term initiatives to meet customer and regulatory requirements.

INNDES references

Developed with the company’s comprehensive technical expertise, INNDES has gained several references with leading Italian companies such as Trenitalia, Trentino Trasporti, Hupac-Rifer, Cosmef, Cespa Manufacturing, and Bertolotti.

In the international market, the company has established stable business relationships with general contractors and railway operators worldwide, which include Siemens, Alstom, Lucchini, SRO and LBX.