RDM, a scientific-production enterprise, is a leading manufacturer of ultrasonic flaw detectors for the railway network over the post-Soviet territory.

RDM was founded in 1993 by former employees of the All-Union Scientific Research Institute of non-destructive methods and means for quality testing of materials and products.

Ultrasonic flaw detectors for railroad lines

The UDS2-RDM-22 flaw detector is designed for revealing defects along the whole length and across the rail section of railroad lines, with continuous testing at a movement speed up to 4km/hr. The detector is also used for the selective hand testing of welded joints, separate sections and rail parts, and for the determination of the revealed defects coordinates and their conventional size.

Features include:

- 16 channels for complete continuous testing and three channels for manual inspection

- Low-frequency channel for testing by means of manual piezoelectric transducer, making it possible to reveal vertical cracks under surface damages and subsurface horizontal delaminations

- Automatic recording of testing results every 1mm of track as the flaw diagrams of the tested portions in the form of B-scan

- Continuous inspection of acoustic coupling

- Possibility of prompt review of the recorded flaw diagrams on the matrix flaw detector display

- The operating temperature range is from -40° to +50°.

Railway track width ultrasonic flaw detector

The UDS2-RDM-23 is an ultrasonic flaw detector intended for testing railway tracks with widths from 990mm to 1,550mm.

Functional distinctions of the UDS2-RDM-23 compared with the UDS2-RDM-22 are as follows:

- Possibility of choosing one of the four improved sounding circuits according to the programme installed for continuous rails testing

- GPS system for obtaining the flaw detector position coordinates over the track

- For each channel of continuous testing there is a system of voice warning about the vanishing of the acoustic coupling in the channel

- Possibility of using wireless headphones

- The flaw detector is delivered in a complete set with specialised coordinate facility for performing more accurate testing by means of a manual piezoelectric transducer with the possibility of obtaining the testing protocol with automatic definition of conventional defect size

Ultrasonic flaw detector for welded rail joints

The USD2-RDM-33 flaw detector is intended for ultrasonic testing of welded joints in rails and other products made of carbon and alloyed steel and alloys. The device interface comprises 32 operating adjustments with pre-set testing parameters, which facilitates the preparation work of the operator. The recording of the testing results, including the oscillograms of signals from defects in the A or B-scan, are saved in the memory of the flaw detector, followed by output to the PC.

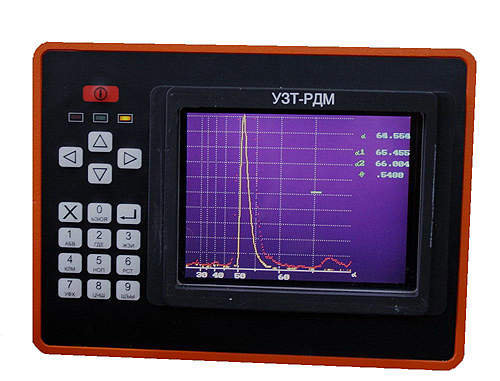

Ultrasonic tester for flaw detectors and thickness meters

The UZT-tester is designed for the metrological checking, normalising and verifying of parameters and specifications of flaw detectors and thickness meters, as well as their component parts, including piezoelectric transducers in the process of manufacturing and operation.

Hardware and software for mobile flaw detector vehicles

The SHC RDM-15k is designed for specialised mobile flaw detector vehicles performing non-destructive en-route testing of rails with speeds up to 60km/hr. Advantages of the complex compared with existing mobile testing means are:

- Usage of 16 channels for ultrasonic rail inspection and two channels for magnetic inspection

- Real-time recording of A and B-scan

- Usage of sounding circuit in the ultrasonic channel by means of wide-span resonators with 45° and 55° entry angles developed by RDM makes it possible to perform more accurate sounding of a rail from both working and non-working sides and to obtain a more extended record of bolt holes

- The possibility of reviewing the recorded data at the level from -6dB up to 6dB relatively to the set sensitivity level

- The usage of RDM-developed non-contact tracking system for mobile means of ultrasonic flaw detection