Oil Analysis Services (OAS) is an independent specialist focusing purely on oil analysis. We do not sell oil, plants or maintenance and our core value is quality science. At OAS we recognise the crucial role we play for our customers and therefore provide high-quality technical support, online recommendations, reports and maintenance procedures advice, along with 24-hour availability.

Oil analysis services for trains

OAS’ laboratories offer a comprehensive range of oil analysis services to clients worldwide. We provide dissolved gas analysis (DGA) and a full range of electrical oil analysis tests for transformers, generators, cables and other electrical plants. We also provide analysis of gearboxes’ oils, engines, hydraulic systems and any other plant/vehicle where oil or grease is used as a lubricant.

Oil analysis for trains’ condition-based maintenance

Companies use oil analysis to improve the efficiency of maintenance spending and cut in-service equipment failures (which can result in heavy costs and penalties). Oil analysis can identify which plant or train needs maintenance and when. It is used for condition-based maintenance rather than ad-hoc, random or ‘mean time to failure’ maintenance programmes (which can give rise to inefficient maintenance spending).

Oil analysis can also be used to identify potentially critical faults early. An urgent analysis can clarify the cause and location of on-going faults or help with post-fault investigations. Additional uses include environmental issues, emissions control and as evidence in a variety of legal issues and disputes.

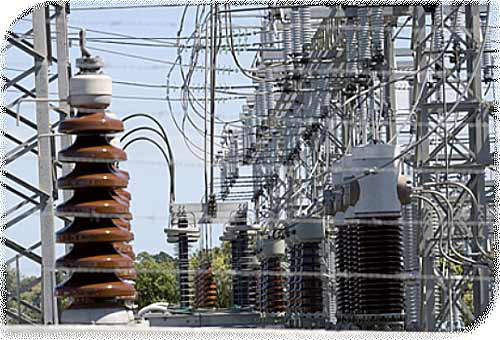

Electrical oil analysis and transformer oil testing

Oil is analysed from high-voltage electrical transformers, including generators and switchgear HT cables that contain insulating oil. Aside from power stations and electricity distributors, many large industrials have their own high-voltage network that can benefit from oil analysis. Train operators are also major users, analysing the oil from high-voltage transformers and equipment on trains.

Basic tests are used to look at the oil’s quality, including testing for water, acidity, electric strength, resistivity, colour, fibres, odours and oxidation. To evaluate the condition of the plant from the oil, more complicated techniques of high-pressure liquid and gas chromatography are used to determine the combination of gases and debris in the oil.

Analysis of industrial oils and greases

Many different oils and greases are used in the rail industry, including fuel, engine, lubricating and hydraulic oils. We analyse industrial oils from all sorts of plants, including mechanical and rotating, moving plant/vehicles, hydraulic systems, pumps, engines and bearings.

When analysing industrial oils we first look at the quality of the oil to ensure it is the correct oil and that it is doing its job. If not, we look at the potential to ‘repair’ the oil via additives, etc.

Oil analysis for condition monitoring, fault diagnosis and plant performance

Oil analysis is used to improve the efficiency of maintenance spending, cut plant operating costs and extend plant life. Oil testing can be applied to any plant that contains oil (or fuel) and greases, from high-voltage electrical systems through to rotating and fixed position plants, including vehicles.

Uses for oil testing include:

- Analysis of oil quality and characteristics to ensure it is performing its intended role

- Unlock information on the condition of the plant itself, for early fault diagnosis and identifying cause and location of active faults

- Perform predictive maintenance, monitor trends to improve maintenance efficiency and highlight slow-developing faults before they become critical (such as causing a train failure on the running line)

- As a post-failure forensic tool after a catastrophic failure and for prevention of future failures

- To prevent costly loss of plants that may involve not only expensive repair or plant replacement costs, but also penalty clauses if failure results in breach of contractual obligations

- For use in legal and contractual issues (warranty, maintenance, etc.)

- Health and safety such as detection of contaminants, e.g. PCB analysis (polychlorinated biphenyls)

- At many levels, oil analysis can be seen as a cost-effective insurance or risk management tool

- Environmental issues such as cutting plant emissions, saving oil (by repair) and reducing plant replacement needs