SAFETRACK® is one of the leading developing and manufacturing companies for high-tech application methods to connect rail cables to steel structures. A speciality is rail connectors for signalling, ground and power supply, and cathodic protection installations.

The company has been located outside Malmoe, southern Sweden, since 1988.

Rail cable connecting methods

We can provide a wide range of cable connecting methods, including pin brazing (silver brazing method), SafeBond® (a low temperature method for connecting rail bonds on sensitive hardened rails), SafePlug® (a drill plug system with silver technology), temporary rail bonds, and track circuit connections.

Rail cable connecting products

We also have a wide range of products for connecting rail cables, including:

- Pin-brazing clips and spring steel clips for attaching cables to the rail

- Catenary system accessories

- Crimping tools, cable-cutting tools

- Safety devices: signal horns, signal lamps, shunting devices, TCOD

- Unique trolleys, called RailScooter and LoadScooter, for easy transportation along tracks

- Work tents and welding tents

- Rail measuring instruments

- Rail and switch heating products

- Gas-bottle heating blankets

- Track tools: rail drills and impact wrenches

Electronic pin-brazing system for rail bonding

SAFETRACK’s patented electronic pin-brazing system is a silver brazing method developed for connecting cables to rails. It is low temperature, corrosion proof, easy to use, portable (battery powered) and has a fast installation time, with the best electrical properties thanks to the silver bonding technology.

The important difference between pin brazing and – for example – thermite welding is that the pin brazing method does not melt the rail down; it is only the silver that melts and creates a molecular bond between the cable and the rail. Furthermore, the operator requires no particular skill.

Rail bond connections for sensitive rails

The close cooperation with our customers and distributors around the world has resulted in several new product lines such as SafeBond (a low-temperature method for connecting rail bonds on sensitive hardened rails). SafeBond started as a project with Union Pacific in the USA.

The patented SafeBond method was developed by SAFETRACK to solve the problem of connecting signalling cables to an extremely hard rail. SAFETRACK used its skills in silver technology to the Union Pacific’s advantage.

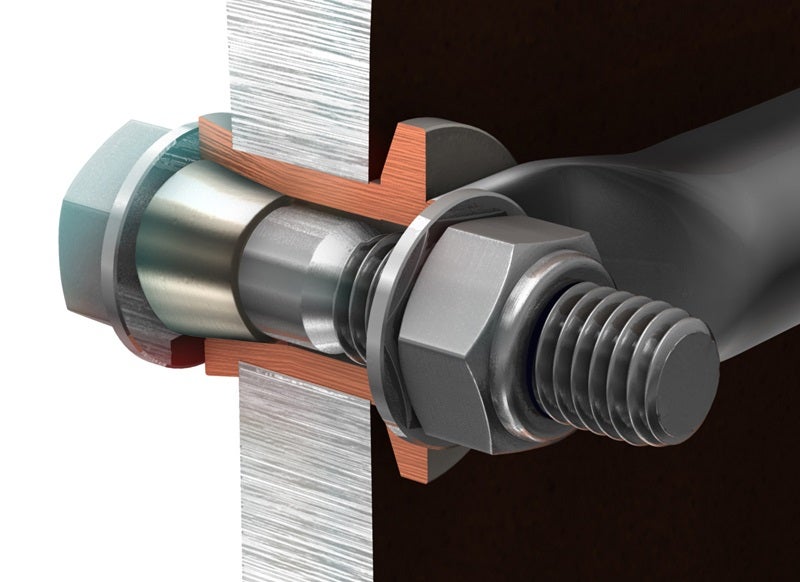

Drill plug system

SafePlug is a patented modernised drill plug system, where one hole is drilled into the web to connect the bond mechanically. The system is superior to conventional drill plug systems because of its silver technology, as together with the use of high tensile stainless-steel bolts it gives a better connection (especially with temperature changes in the rail in mind).

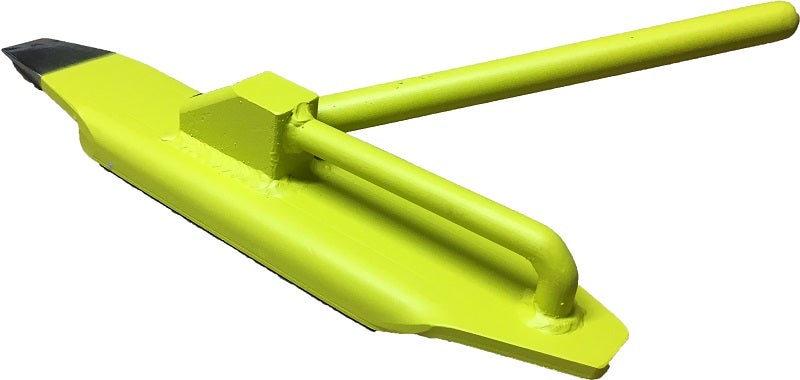

Temporary rail bonds

SAFETRACK temporary rail bonds are used when one does not want to connect cables permanently. They have proved their reliability over decades and require no maintenance.

Track shunting devices

Our track shunting devices are used for shunting rails in case of an emergency or before track works. They are the main shunting devices for railways in countries such as Denmark, Finland and Sweden.

Track-circuit operating device

Another SAFETRACK shunting device is our track-circuit operating device (TCOD), which is the only fully approved TCOD for Network Rail (in the UK).

Rail scooters for track-work transportation

The company has developed rail scooters that are used for either track works along the track, or for inspectors or management, for far easier and quicker transportation than using motorised rail vehicles or walking.

Gas-bottle heating blanket

For track welders, a gas-bottle heating blanket has been developed that allows the propane gas bottles to be 100% emptied and produce higher quality welding results. SAFETRACK resell heating products for the rail industry.