Savage hydraulic presses have been known for over 45 years throughout industry for their rugged construction and durability. Each press is built with pride by our team of experienced craftsman. All engineering and manufacturing is at our facility in Cleveland, Ohio, USA.

Wheel and bearing-mounting, rail bending, frog straightening and locomotive coupler assembly presses

Savage manufactures presses for the locomotive, track and railway manufacturing industries. Each press is available in many sizes and capacities. Its applications engineers will review your requirements to assist you in determining the type and size of press best suited for your work.

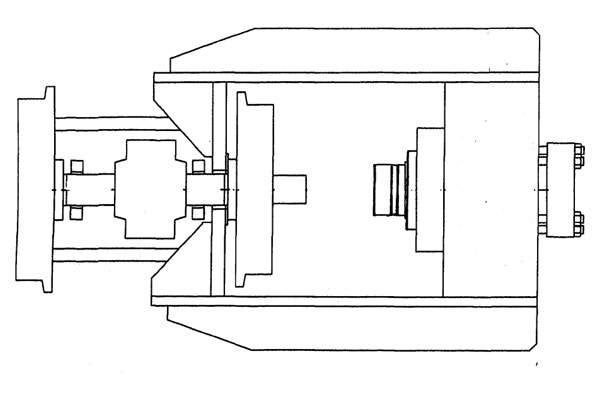

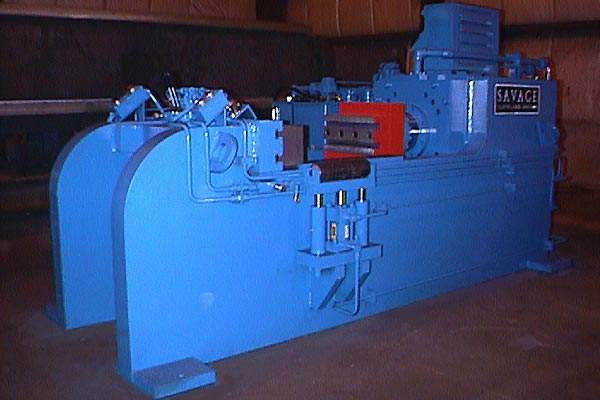

Wheel presses

Wheel presses, also known as horizontal-forcing presses, are used for mounting / demounting railcar wheel-set components such as wheels, bearings, gears, etc. on to / off of axles. Single and double-end presses have roller-mounted crossheads for ease in positioning.

50t to 1,000t capacity models are available. They can have powered or manual crosshead-positioning and a rail-mounted axle support carriage. Push-button ram control and handheld-control pendant are provided.

Pressure / distance recording can be provided using a computerized system or a simple touch-screen interface with a paper printer, to generate mounting diagrams in accordance with AAR requirements.

Frog straightening presses

Traveling gantry straightening presses from 100t to 2,000t capacity are used for straightening plates or castings such as manganese crossings (frogs) and switches for railroad switch yards. Traveling gantry presses allow the work to remain stationary while the ram travels over it.

Savage TFS straightening presses have three axes of ram movement specifically designed for straightening railroad frogs. They can also be used for bending large plates, castings or weldments. With these travel gantry straightening presses, the work piece remains stationary while the pressing ram traverses to the high spot.

Hydraulic work lifters

Hydraulic work lifters can be installed in the bed to assist in positioning the anvils or shims under the work. These work lifters free up overhead-crane usage.

Assembly and specialty presses

Savage manufactures a wide variety of assembly and specialty presses in 100t to 1,000t capacities for a full spectrum of industrial products. Presses are available in C-frame, four-post, horizontal and gantry type construction to meet your requirements.

Applications include locomotive and railroad component assembling, crimping, bending, staking and pressing of parts, and insertion of bearings, seals or bushings into your product. Savage pullers are horizontal-acting gear pullers and car wheel pullers.

Rail bending presses

Savage manufactures a horizontal, bulldozer-type hydraulic rail and track bending press. The rugged press includes hydraulic–lift conveyor rollers at both entry and exit sides to assist with track movement through the press. These horizontal presses are also used for straightening of long bars and structural materials. Lever-operated ram control or hand-held pendant are also available.

Spring presses

Savage spring presses allow presetting of tension for railcar coupler springs. These presses allow overhead loading of components, before the compaction gantry subsequently travels over the component to perform presetting. These machines incorporate a force-distance meter to accurately measure psi of spring compression over a specific distance. The assembly is then retained by a heavy nut.

Passenger car safety for both cab and trailer is maintained with a historical record of both force and distance values met for each coupler.

Custom-built rail and locomotive presses

Savage also offers specially designed, custom-built presses to meet your specific industry needs. Savage pressing systems are specifically engineered to meet your exact requirements and designed to perform their job function as efficiently as possible. Every press is stress-analyzed and constructed of fabricated weldments – no breakage-prone castings are used in any Savage press.