Trelleborg Industrial AVS (TIAVS) is a world leader in providing solutions for the rail industry, specifically the design and manufacture of rubber to metal-bonded products and assemblies for anti-vibration applications and suspension systems. These are specified by virtually every major manufacturer of bogies, rolling stock and locomotives around the world, for applications from metro, light rail and commuter to high-speed and heavy freight locos.

Wherever they are used Trelleborg Industrial AVS components contribute to the comfort and safety of the passenger and the security and cost-effective reliability of operators.

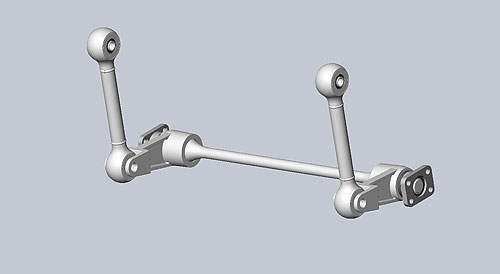

Train suspension systems, control mountings and links, and drive couplings

Trelleborg Industrial AVS is best known in the rail industry for its Metalastik® branded products. These include primary and secondary suspension systems, centre control mountings, centre pivot bearings, control links and drive couplings for every type of application from trams and light rail to heavy freight locos. For the secondary suspension, the company offers a variety of products including air springs, all-rubber hourglass bearer springs and airspring systems, while chevron and Metacone® springs are typically used in primary suspensions.

Airsprings for the rail industry

The Metalastik® air spring combines large horizontal displacements and low frequency ride characteristics in both normal and emergency conditions. The system’s progressive force/displacement characteristics help to make vehicles extremely stable in operation, particularly where the patented half hourglass design is used within the system. In addition, the ability to accommodate high horizontal, torsional, and conical displacements make the Metalastik® design an ideal solution for bolsterless bogies.

Auxiliary systems for the rail industry

The company provides a wide portfolio of products for auxiliary systems. These include resilient wheels inserts and powertrain mountings. Another recent introduction is a resilient mount used for permanent way installations, specifically designed to reduce ground-borne vibration, which can cause secondary effects of noise and even structural damage in neighbouring buildings and transit tracks. The design consists of two metal components – the top plate and frame, bonded together with an elastomer, normally rubber, specially compounded for lifetime spring performance and dynamic stiffness.

Design and manufacturing services for the rail industry

In addition to its wide range of rail-specific products, Trelleborg Industrial AVS offers a unique reservoir of elastomer expertise and what is probably the most extensive catalogue of rubber formulations in the industry. This and the experience embodied in our expert teams of development and applications engineers is the key to Trelleborg’s rail offering. It is a combination of design skills and manufacturing excellence that ensures Trelleborg Metalastik® products not only work first time, out of the box but also offer long, trouble-free service and proven whole-life cost benefits.

About Trelleborg

The company’s headquarters are located in its state-of-the-art plant in Leicester, UK, which also houses the core technical resource and its research and development unit. Production is primarily based in Leicester, whilst there is also a highly developed engineering and sales support team based in Europe, Asia and North America. The Trelleborg strategy is to make the company’s technology available on a local basis in all the world’s major rail markets. This is achieved through technical innovation, a cross-disciplinary sales organisation with local dedicated engineering back-up and, thirdly, local manufacturing to provide a high level of local content.