Welser Profile manufactures bespoke metal sections and complex profiles made from steel, stainless steel and non-ferrous metals for applications across a range of markets, including rail vehicle assembly, commercial automotive and the construction sector. The firm has been forming steel since 1664.

Advanced cold roll forming technology

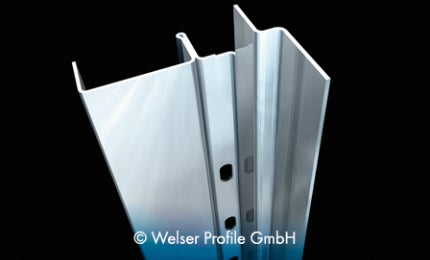

Welser Profile uses advanced cold roll forming technology to produce a customised steel or stainless steel profile on a single roll forming line. Up to 60 roll forming stages can be combined with complex online hole-punching patterns, welding , joining and bending processes, as well as further downstream handling to create the perfect solution.

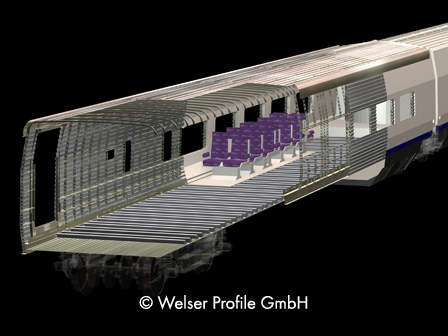

The firm works closely with its clients to understand, develop and optimise their requirements. It develops complex metal sections for a wide variety of applications within the rail vehicle construction industry. Examples include belt rails, door rails or wall reinforcements, suitable for a range of passenger train, tram or metro applications, whether in the side or end walls, roofs or undercarriages. Welser Profile’s metal sections guarantee a safer arrival.

Bespoke, roll-formed metal sections

Extremely long, heavy gauge, complex sections are fundamental elements of the roll formed steel profiles found in the rail industry.

Welser guarantees its products have exact dimensions, as well as very tightly controlled straightness and twist tolerances. The combination of a highly accurate metal section consistently produced to a bespoke design means Welser profiles facilitate simpler, faster rail vehicle production.

Stylish, bespoke and reliable rail vehicles can be produced on a framework of high quality rolled metal sections to a standard that exceeds the customer’s expectations.

Welser enjoys being part of its clients’ project planning, offering help from design concept to production run. The firm gathers detailed information about the customer’s product requirements, including the function and application to enable it to optimise the cross section. Together with its client base, Welser has developed more than 20,000 metal sections, and is developing new metal sections every day.

Cost-effective online processing capabilities

Superior Welser online processing capabilities allow additional features to be added and / or weight reduction measures to be performed in highly economical, efficient production processes specifically aimed at optimising form and function, while lowering cost.

If required, several individual metal sections can be combined to produce a complete profile system, ready-to-install directly into the rail vehicle.

As well as profiles that are welded closed, complex open profiles can be bent to follow complicated rail vehicle design contours.

Welser is committed to ensuring that the quality of its products is maintained during the transportation process. Appropriate packaging is specifically designed to meet individual profile requirements to provide maximum protection in all modes of transportation. The firm also has excellent transport links, including an on-site rail link; and it offers its experience in global projects.