The rail industry is committed to investing millions of pounds in improving quality through renewals and maintenance. Productivity and efficiency are key to delivering value for money during this process.

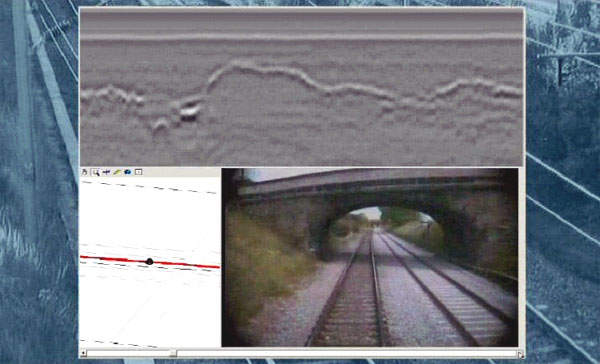

For a number of years Ground Penetrating Radar (GPR) has offered a means of potentially identifying incipient trackbed problems such as wet bed formation, ballast pumping and ballast degradation, and sub-grade failure.

ZARR – ADVANCED RAIL RADAR SYSTEM

Zetica has developed the innovative train-mounted Zetica Advanced Rail Radar (ZARR) system. ZARR offers the following two main benefits:

Major efficiencies and cost savings compared with existing trackbed evaluation methods: data is acquired using any measurement or in-service train platform and trackbed information can now be acquired alongside track geometry and asset mapping data.

More efficient planning and execution of trackbed maintenance through monitoring of trackbed deterioration over time, identification of sites for renewal by ballast cleaning before degradation reaches the stage where costlier machine reballasting is required, and quality control of renewals through pre- and post-renewal scanning.

The system also provides for:

- A predictor tool of ballast deterioration rates that will facilitate the development of reballasting strategies, leading to timely intervention before speed restrictions are applied

- Improving the quality of desktop assessment, and potentially reducing the number of sites that need full investigation by up to 5%

- The planning and resourcing of site investigations, especially for quantifying numbers of trial holes, it is anticipated that this can reduce the number of track possessions by 10% to 20%

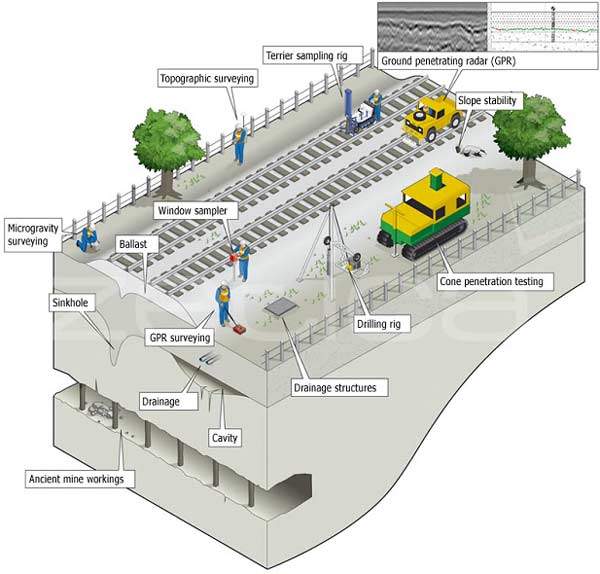

TRACKSIDE SERVICES: INVESTIGATING THE RAIL ENVIRONMENT

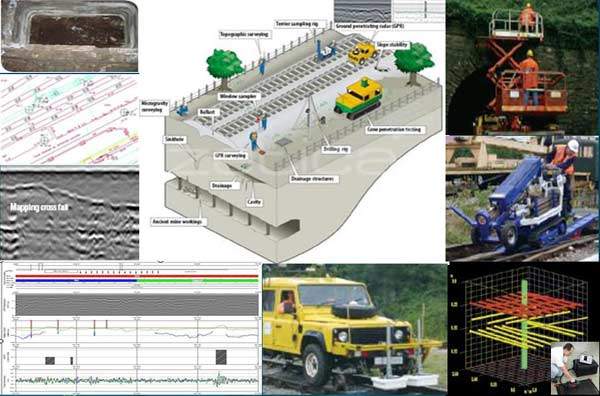

Zetica also provides its Trackside service offering detailed site investigation of the rail trackbed and its surroundings.

Utilising a combination of traditional site investigation methods and non-intrusive techniques, Zetica can provide information that enables a better assessment of ballast, formation, drainage and other key trackbed conditions:

- Drainage: assist in characterising existing drainage including visual catch-pit inspection, mapping location and investigating condition

- Ballast: using GPR and targeted sampling during various stages in the life of a trackbed, stages include targeting renewals, designing trackbed, quality control following renewals and interim assessment of ballast condition

- Formation: non-invasive geophysical techniques and minimally invasive cone penetration testing methods combined with conventional intrusive SI methods such as trial pits and cable percussive boreholes

- Subsidence: former mine workings and in-filled sinkholes can represent a significant risk to the safety of a railway – a range of geophysical methods suited for use in the trackside environment are offered that can help identify the location, depth and size of structures

TOTAL ROUTE INVESTIGATIONS

Zetica utilises GPR on road-rail (up to 30kph) or trolley platforms with targeted sampling to:

- Scan below wooden and concrete sleepers

- Scan between sleepers at centimetre resolution

- Provide multi-profiles in a single pass for building lateral cross sections

- Integrate track video, thermal infra-red and ballast sampling

- Allow auto ballast sampling to be included in a single line possession

ONE-STOP TRACKSIDE INVESTIGATION SERVICE

Zetica offers the following full range of trackside site investigation services and structural surveys:

- Ballast condition surveys

- Ballast sampling

- Ballast contamination assessment

- Asset condition reporting

- Drainage inspection

- Utility mapping

- Slope stability surveys

- Detailed topographic mapping

- Cavity detection

- Detection of mine workings

- Borehole geophysics

- Cone penetration testing

- Non-destructive testing of structures

- Thermal imaging