At PCC we are market-leading experts in composite production, and have been providing interior solutions with experience in the rail industry going back to 1988.

Our own-design Universal Access Toilet (UAT) is proof of our cutting-edge creative ability. Conceived, planned and engineered all in-house, it is now established as the ‘must-have’ solution for leasing companies to meet legal requirements by 2020.

But there is much more to PCC than merely our award-winning UAT. That is just an example of the company’s commitment to creating custom-built solutions for customers throughout the transport industry.

Based in Cwmbran, South Wales, the company has been under fresh, dynamic management since 2015. A new streamlined factory design has built-in capacity for growth to meet bigger worldwide orders, but our state-of-the-art facilities still put quality at the heart of everything we do.

PRM-TSI Compliant Universally Accessible Toilet

We supplied the first UATs as long ago as November 2012, and by now we have hundreds of units in service, built and installed by our skilled craftsmen, with minimal maintenance costs and massively positive customer comments.

The module has been adapted to suit more than nine classes of vehicle over 20 different fleets, with more projects in the pipeline. By 2020 around 95% of UK trains will be running with our UAT on board.

We started our design process by listening to what the industry wanted, and evolved a product that ticked every box:

- Increased energy efficiency

- Reduced water storage

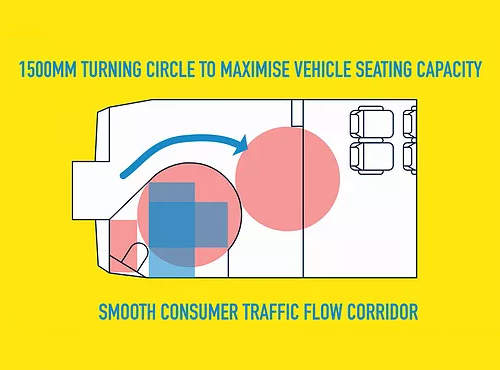

- Minimised seat loss when benchmarked against alternative solutions

- Reduced maintenance costs

- Engineered solutions to suit vehicle integration

- Fully certified product compliance standards and in many cases exceeding them

Custom solutions

After 30 years of experience making interiors for the rail industry, we are streamlined to create products that answer individual needs. Our design team listen to the brief, create solutions, and fully consult on the research and development of new products.

We have in house pattern making and mock-up design visualisation facilities to create accurate prototypes. This helps make sure we get it right before going into production rather than cost our customers time and money by making changes further down the process.

All our products are tested to industry standards and pre-agreed customer specifications, and we go on testing once they are in service to ensure continuous improvement and realistic preventative maintenance periods.

Manufacturing

We have invested massively in our modern plant in Cwmbran, now structured to follow LEAN principles with a highly skilled, highly dedicated and highly motivated work force. Our equipment has been upgraded to state of the art composite production with full safety standards.

We agree specifications, timetables and quality standards with our customers before starting work, and our manufacturing process has a rigid quality control system built in to ensure complete compliance.

Innovation

At PCC we’re proud that we don’t just make things, we create them. The company has a long tradition of innovative design solutions with the UAT, which answered the need of the UK rail industry and is now attracting interest from rail companies worldwide, as the ultimate example.

Talk to us about your needs and we’ll create the right product for you too – and then deliver it on time and on budget.