TRB Lightweight Structures is a Tier 1 supplier to UK and European train builders, providing high-quality, lightweight interior solutions.

This includes universal access toilet modules, structural partitions, high-use doors, detrainment doors, train manager offices, shop and catering units, magazine racks, stock rooms, coffee units and bike storage areas.

All solutions are supplied fully assembled, featuring components such as doors, glazing, lights and electrical sockets.

Fully equipped products made with composite materials

TRB provides cost-effective products that often outperform the original components. The company supplies a complete, fully equipped product, which is painted in its in-house facility and supplied ready-to-fit into the vehicle. Damaged items are handled in the same manner, reducing out-of-service times and costly delays.

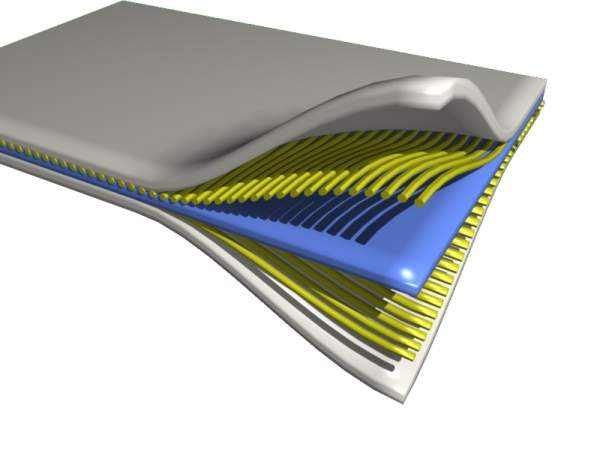

TRB uses prepreg (PREimPREGnation) and infusion technologies, processing carbon, glass and aramid fabrics in a wide range of woven and unidirectional formats.

TRB has strong relationships with prepreg manufacturers and a number of its sandwich panels are produced with proprietary prepreg resin systems, which were developed specifically for the company. TRB uses both vacuum-bagging and press-moulding processes to cure fibre-reinforced plastic (FRP) panels and components.

Rolling stock refurbishment and reverse engineering

Refurbishment of current rolling stock is often a cost-effective solution, even if original design documentation has been lost.

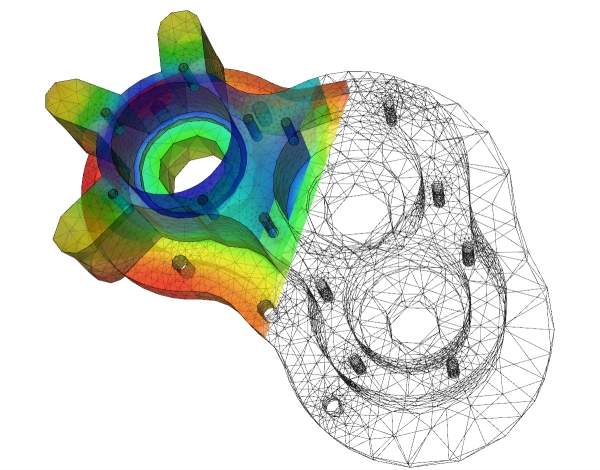

TRB reverse-engineers physical parts by using a Faro coordinate measuring machine, which interfaces with the company’s 3D modelling package. This lets TRB accurately produce 3D drawings whose originals do not exist or are incomplete.

Once the component’s external dimensions have been recorded, the product is cautiously stripped-down and each individual part measured in order for it to be redrawn.

Universal access toilet modules for rail vehicles

The TRB universal access toilet (UAT) module is available in standard and PRM-TSI compliant models and can be easily adapted to suit most rail vehicles. The module meets the installation requirements of all UK rail vehicles, including Class 150, 153, 156, 158, 159, 16X, 31X, 32X, 442, 46X, and HST Mk3 coaches.

With its modular design and construction, the UAT module is easily adjusted to suit different space requirements and is available in right or left-hand design for total flexibility in positioning.

To ensure reliability in the field, proven materials were specified and significant testing was completed on critical parts and assemblies, for example, the door operating mechanism has cycled 0.8 million times without failure, replicating a 15-year lifetime at 18hr a day and 190 cycles a day.

Materials and components have been chosen for their proven reliability, as well as their expected long-term availability, in case they become damaged or need replacement during the service life of the toilet module.

Interior, exterior, detrainment, egress and cab security rail doors

TRB designs, builds, paints and assembles the operating mechanism, as well as installs a wide variety of doors, ranging from simple hinge doors to complex, plug-slide doors and fold-out steps.

In-house test rigs can accommodate all types of testing from load tests to simulated evacuation tests.

About TRB

TRB has a team of experienced composite engineers, who design simple to complex structures with an understanding of lightweight material performance and manufacturing.

The company also supplies trained and rail-authorised personnel to assist with the installation of products and equipment. In addition, a 24/7 response to in-service queries is available, including rapid delivery of parts and spares.

As well as ISO 9001 certification and a host of individual customer quality approvals, TRB holds the prestigious IRIS approval, which clearly demonstrates the credentials needed to be a leading supplier to the international rail industry.