Banlaw produces unified fuel management equipment and hydrocarbon management solutions. The company helps rail companies improve their productivity by increasing fuel efficiency, reducing fuel contamination, and delivering safer rail refuelling.

Unified fuel management for railway operations

Banlaw is a specialist in diesel fuel management, and has extended its expertise to cover all hydrocarbons in general, as well as management of other liquids.

The company can provide you with hardware, software and services to ensure the safe handling and use of coolants, grease, oil, and fuels, as well as optimising storage.

High-speed rail refuelling

Banlaw believes in delivering the best possible service. The company is focused on providing safe and efficient products that enhance the productivity, durability, speed and accuracy of clients’ services.

In-line refuelling for unattended diesel-fuel transfer

In partnership with Australian rail freight operators, Banlaw has engineered high-performance in-line refuelling systems to allow for unattended diesel-fuel transfer in scenarios such as extended long-haul journeys.

Banlaw Bulk Fluid Transfer Couplings incorporate extra safety features to ensure they stay connected and avoid fuel spills in a constantly moving, and high-vibration application.

Locomotive servicing

Banlaw’s solutions control contamination, reduce wear and manage clients’ fluid assets. The company is focused on revolutionising the approach to rail servicing, and one method of doing this is by locating access points for servicing or provision of diesel fuel and hydrocarbon products near to one another in a more efficient design.

The Banlaw Evacuation Coupling (BEC) is another such innovation. One common coupling can be used to remove waste products from different sized receivers, without needing to change the mating nozzles, increasing efficiency.

Efficient fuel management equipment

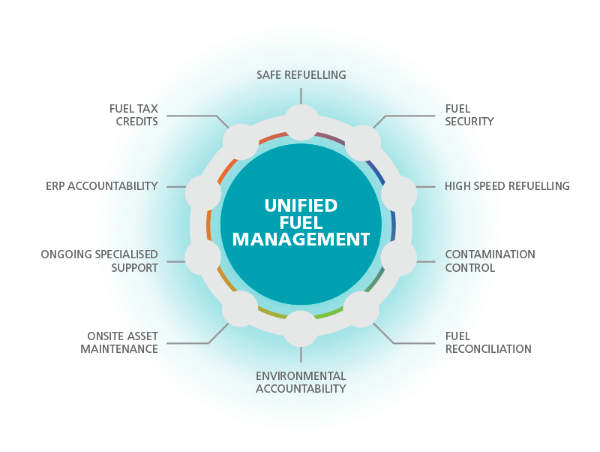

Banlaw has a specialised approach to managing hydrocarbons, called ‘Unified Fuel Management’ (UFM). This system delivers efficiency and cost-effectiveness, optimising all aspects of refuelling and hydrocarbon management across clients’ fleets.

The company’s customers can achieve a reduction of up to 70% in tank fill times, just by transitioning from filling locomotives that operate at around 300l/min up to 1,000l/min. With a 14,000l tank, refuelling is reduced from 47 minutes to 14 minutes.

Scalable fuel management systems

Banlaw’s FuelTrack™ fuel management system (FMS) is one of the only complete solutions on the hydrocarbons market, including fuel management software design, hardware manufacturing, and service.

The system scales from a single refuelling station to numerous bulk storages for thousands of locomotives, spanning entire continents.

Robust refuelling products to extend tank life

Rail operators who currently refuel at 300l/min to 500l/min could cut times by up to 50% simply by installing the appropriately matched Banlaw dry-break nozzles, receivers, and tank vents.

Banlaw also has a cold-temperature range of products, which can help refuelling systems to keep operating, even in cold climates down to -40°C.

Other Banlaw refuelling hardware includes high-speed vents and auto shut-off nozzles to provide overfill protection. FillSafe Zero is a pressureless overfill potection system engineered to extend tank life.

About Banlaw

Banlaw is based in New South Wales, Australia, designing, engineering and manufacturing its own products and software. The company operates on a global scale, and has a network of trained distributors around the world who provide expert sales and service at a local level.