IGW is an industry-leading provider of transmission solutions for the rail industry. We design and manufacture customised gears, gearboxes, shafts and housings, as well as provide specialised services for demanding railway applications.

With 65 years of experience, we have the heritage, ability and drive to meet all your requirements, and achieve the highest possible quality. Whether you require an existing part, or you are developing a completely new application, we can supply you with a customised solution to suit your exact needs.

Our state-of-the-art processes, highly skilled employees, and a passion for innovation have made us a trusted partner for clients around the world.

Specialised gear systems for the railway sector

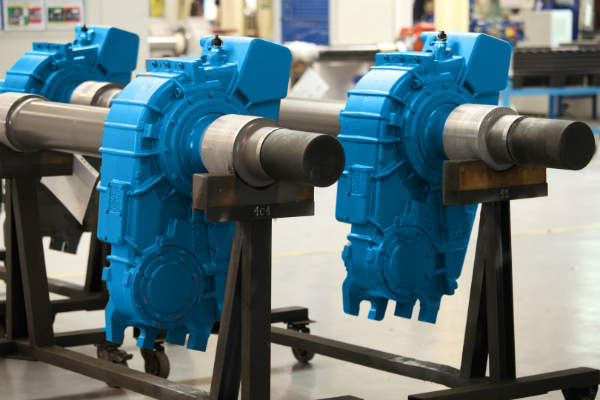

IGW supplies unique, robust and efficient gear systems, which focus on minimising required maintenance and noise. From heavy-duty locomotive to light rail applications, and from low-speed city metros to high-speed trains, we provide a complete spectrum of products for the highly specialised rail market.

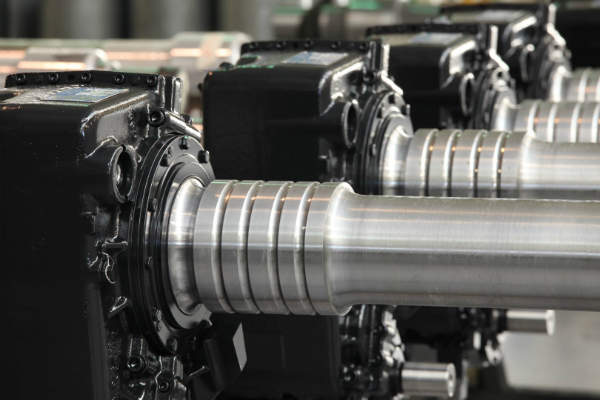

We create a variety of gear solutions for railway applications worldwide. We are experienced in a wide range of vehicle types and gearbox designs, including wheel and axel-mounted, fully and semi-suspended, single and double-helical, bevel and bevel helical gear units.

Comprehensive transmission and engineering solutions

IGW handles all drive configurations (fully, semi or half-suspended), as well as combinations of helical and bevel gears, all coupling types and a range of housing arrangements.

We supply both loose gears and complete systems, comprising gearbox, couplings, reaction rod, and support elements, as well as adapt to existing supply chains. The design standardisation of our labyrinths, covers and bearings delivers valuable cost advantages for our customers.

IGW resolves a range of transmission problems, including limited space, frequent stop-starts with high-torque values, and maximum loads.

Transmission repairs and services

IGW performs a wide range of service jobs, offering investigations, repairs, overhauls and spare parts for original EOM components.

Thanks to our worldwide presence, we can guarantee rapid response and minimise downtime. Our highly trained service engineers provide in-depth support, and follow detailed working procedures. This way, they can diagnose the source of the inconvenience, and implement measures to eliminate it immediately and permanently.

Every servicing job is concluded with extensive testing and inspection, and meticulously described in a service report.

Expertise from global rail infrastructure

IGW has an extensive global presence, with locations in Belgium, Romania, the Czech Republic, China, the USA and India. This global capacity means we can bring production closer to the customer, resulting in shorter lead times and greater responsiveness when it comes to customer service.

We have been involved in more than 250 major rail projects around the world, covering trains, trams and metro, as well as high-speed trains in the People’s Republic of China. Our global presence means our gears and gearboxes operate in adverse environments, ranging from extreme heat in Brazil to the arctic conditions of Norway.