In Liljedahl Bare Wire the companies AB Elektrokoppar (Sweden), Isodraht (Germany) and Liljedahl Wire (China) form a vital production and sales division within the Liljedahl Group.

Liljedahl Bare Wire is a leading supplier of copper wire rod, wires, stranded conductors, profiles and overhead catenary systems in aluminum, copper and copper alloys. Our products are used, among others, in cables and railway products (contact wire, stranded conductors, dropper wire, feeder cable) wherever infrastructural investments are required.

With us, you get a strong global partner with a wide geographical presence and a deep knowledge of the local markets. We are driven by the power of permanent improvement – and always with the customer in focus. The result is high quality products, reliability, attention to details and a strong technical partnership.

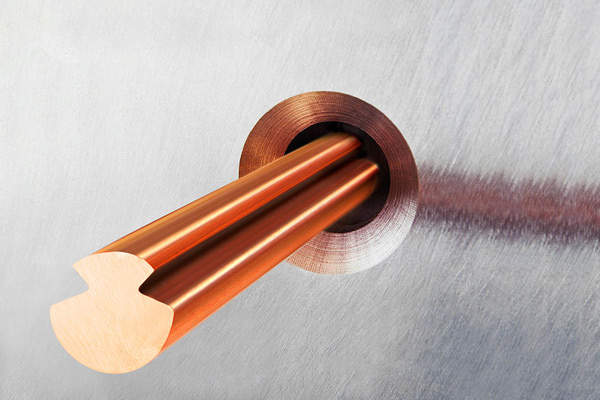

Contact wire and stranded conductors

Liljedahl Bare Wire produces contact wire and stranded conductors with a high consistency of all properties, which provides a high degree of reliability during handling and assembly.

We supply contact wire made from ETP-copper, silver, tin or magnesium alloy, and cable conductors,(stranded conductors, messenger wire and droppers) made from ETP-copper or magnesium alloy (BzII according to DIN 48200 ff standards).

Grooved contact wires

Liljedahl Bare Wire supplies grooved contact wires made from copper (Cu-ETP), copper-silver alloy (Cu-Ag), copper-magnesium alloy (Cu-Mg) or copper-tin alloy (Cu-Sn).

Drums and lengths can be customized according to the customer’s requirements. Shapes are available according to international standards on request.

Contact wire for high-speed trains

High-speed trains such as the ICE make particularly high demands on the railway’s control system. For this application Liljedahl Bare Wire offers special CuMg wire – ELCORIM combining high tensile strength with the highest conductivity and world leading properties above EN 50149.

Our range of contact wires includes:

Pure CU-ETP contact wire

Cross section 80-150mm² for conventional use in commuter systems: speeds up to 160km/h.

CuAg 0.1% contact wire

Cross section 80-150 mm² for use in long-distance passenger systems: speeds up to 250 km/h.

CuMg 0.2% and 0.5% contact wire

Cross section 100-150mm² for high-speed routes: speeds up to 400 km/h.

CuSn 0.2% AND 0,4% contact wire

Cross section 100-150 mm² for high-speed routes: speeds up to 300 km/h.

Process knowledge & quality management

Fast railway lines with speeds above 350 km/h demand a professional quality assurance system throughout all sectors of the company. Liljedahl Bare Wire stands for many years of experience in the manufacture of contact wires.

Following the demands of our quality system we work to continuously improve the entire production chain by implementing the ISO: 9001 quality managing system. It is your guarantee and our basis for superior products.

Modern production equipment and high-tech processing experience are the basis for our product quality. Throughout the years, Liljedahl Bare wire has built up a strong reputation of innovation: “The Power of Permanent Improvement”.