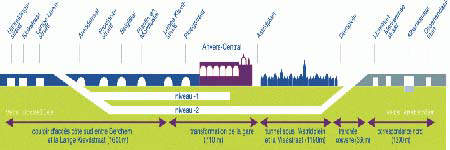

Lamifil designs, manufactures and supplies a complete range of high-quality catenary wires for railway electrification, from urban transport systems to high-speed rail networks.

Our products enable our customers all over the world to run more trains at a lower cost, to prepare rail systems for the future, boost conductivity and lower their CO₂ impact.

Our product range meets the highest customer demands for diverse railway electrification projects in urban and cross-border settings, from conventional to high-speed lines. Our offering includes the entire spectrum of bare wires used in electrically operated railway infrastructure, including contact wires, messenger wires, dropper wires, feeder cables, and auxiliary cables.

Our alloys and innovations

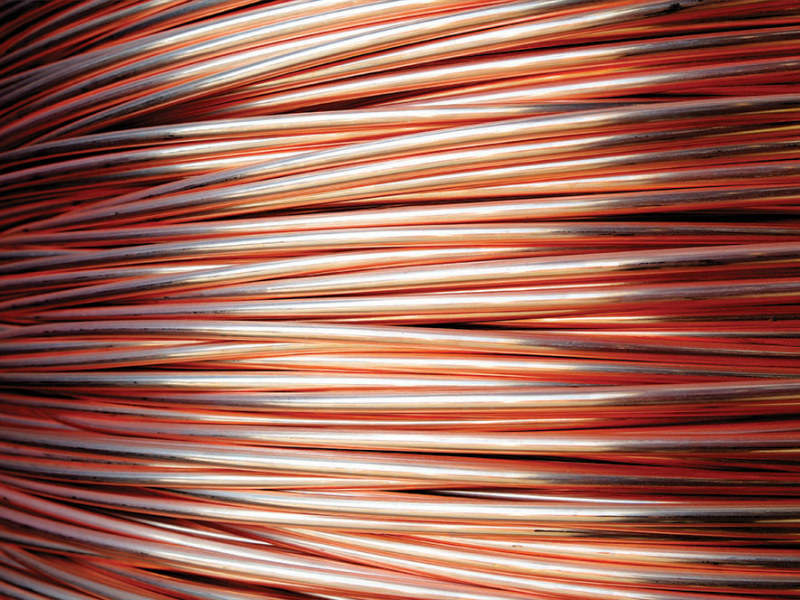

Our R&D engineers continuously look for ways to improve the mechanical and electrical capabilities of our copper-based products and alloys. We supply catenary wires in copper, copper-silver (CuAg), copper-tin (CuSn), copper cadmium (CuCd) and copper magnesium (CuMg). Our latest innovations includes PowerFil, a ground-breaking new high-performance copper alloy to address modern railway grid challenges.

PowerFil is a next-generation alloy that can be used in multiple applications for railway electrification, such as messenger and contact wires. Its properties outperform conventional CuMg alloys. This highly efficient ‘green’ alloy offers approximately 23% better resistance than standard CuMg 0,5 alloys. PowerFil allows operators to save up to €12,000/km during the lifetime of a messenger wire.

Contact wire

Lamifil manufactures trolley wire or contact wire according to internationally recognised standards as well as customer specifications. Features include:

- Sections ranging from 65mm² up to 150mm² and above

- Round, flat, oval profiles

- Available in copper, copper-silver, copper-tin, copper magnesium and copper cadmium

- Specifications: EN, NFC, DIN, UIC, BS and ASTM

Different sections or different alloys will be used depending on the type of lines such as heavy traffic, normal operation, high-speed lines.

Messenger, feeder and dropper wire

Lamifil manufactures bare overhead electrification conductors in copper and copper alloys according to internationally recognised standards and customer-specific requirements or specifications. Features include:

- Sections ranging from 10mm² up to 1,400mm²

- Messenger wires, dropper wires, feeder wires and flexible strands

- Available in copper, copper-silver, copper-tin, copper magnesium and copper cadmium

- Specifications: EN, NFC, DIN, BS and ASTM

Moreover, Lamifil produces a complete range of aluminium and aluminium alloy conductors to connect catenary wires to the power supply grid. Lamifil is therefore your ‘one-stop-shop’ for a full range of bare conductors used in railway electrification.

Wire rod and drawn wire

For overseas markets, Lamifil can offer finished products as well as the wire rod or drawn wire used to produce the conductors for overhead electrification. Wire rod in copper-magnesium (CuMg) or copper-cadmium (CuCd) is available in a wide range of diameters. Wire rod in aluminium alloys is available in several diameters as well.

Our experience around the world

Lamifil has over 90 years of experience. We currently have over 100,000km of catenary wires installed in over 30 countries all over the world. In addition to our high-quality products, we offer flexible services and full technical support at any and every stage of your project. Among Lamifil’s key accounts are leading international railway contractors and railway infrastructure operators active in tramways / LRT, conventional rail infrastructure and high-speed rail.