Williams Advanced Engineering’s unique traction power energy recovery and energy storage system for DC metros and urban railway systems employs proven composite flywheel technology and delivers reduced investment costs, reduced operating costs, impressive CO2 savings, improved capacity and increased reliability and performance.

Clean power concept – recovering, storing and recycling energy

In electrified urban rail environments (suburban rail, metros, light and ultra-light rail) trains undergo constant stop-start cycles as they slow down into stations or at signals and then move off again.

Normally a train brakes by using the traction motors or friction brakes (or both). In these cases, if the transfer of energy to another train – receptivity – cannot be optimised, the braking energy of the train is lost as heat. As trains are heavy and move at high speeds, the amount of energy lost every time the train slows is considerable. In order to accelerate the train, the traction motors draw “new” power from the electrical supply to generate torque at the wheels. This is an expensive use of power that can lead to power demand surges or shortages across the network.

Electrical cable energy transfer

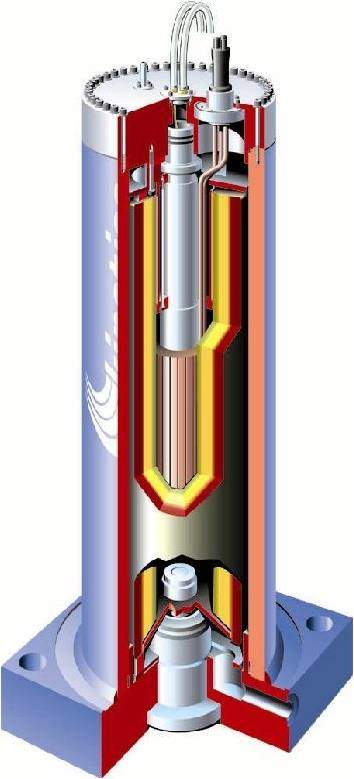

As a train brakes, the energy generated by the traction motors in slowing down is normally lost to the atmosphere as heat energy. With a flywheel energy storage system, this energy is instead transferred via electrical cables to a flywheel that sits beside the track where it is stored via a composite rotor that spins at up to 38,000 rpm.

As the train prepares to move away, the flywheel slows down and releases the stored energy back along the electrical cables to the traction motors, providing a free power boost of recycled energy. In effect, the system emulates 100% receptivity and is over 90% efficient. Because the braking energy of the train is not lost as heat, and is instead re-deployed, the net energy consumption of the train is significantly reduced.

Optimised traction power on electrified railways

Optimising traction power is a key enabler to increasing capacity and improving reliability on electrified urban railways. By providing an additional source of power to the train’s traction motors, the flywheel reduces the voltage and power demands on the electrical network. This provides the opportunity to increase train capacity on an existing network during peak times. At the same time costly network upgrades can be avoided by augmenting the network with the flywheel energy storage, or new network specifications can be “downsized” to achieve the same peak capacity.

Simulation and analysis tools to save energy and reduce costs

Using Williams’ in-house simulation and analysis tools, the energy saving from integrating the flywheel energy storage system in a typical metro application can be as high as 30% (dependant on the duty cycle, type of train, headway, distance between stations, passenger loading, number of flywheels, etc.). This energy saving results in a direct reduction in operating electricity costs and CO2 emissions.

This technology provides a real opportunity for operators, end users and the industry as a whole to improve its carbon footprint and reduce costs at the same time.

Reduced heat generation

Due to the constraints of conventional suburban and metro transportation, it is not uncommon for the heat generated from braking to cause issues for equipment operation, lead to passenger discomfort, and increase the risk of heat strain – a particularly critical issue in the event of a stalled train in a tunnel. Expelling this unwanted heat presents cost, energy and technical challenges. The Williams energy storage solution reduces these problems because the heat energy caused by braking is redeployed, not dissipated.

Emergency power for automated metros

A further benefit of the Williams system is the ability to provide emergency or supplementary power in the event of network power outage or power unavailability. The stored flywheel power can be used to power emergency systems or provide limited “limp-home” capability to the next station, a very important function for automated metros.

One of the key distinguishing attributes of the Williams flywheel system is its long useable life of between seven and ten million deep charge-discharge cycles. Ten million cycles equates to approximately one charge-discharge cycle every minute, 24 hours a day, 365 days a year for over 19 years. This makes the lifecycle cost of our technology particularly attractive when compared with other forms of energy storage such as ultra-capacitors (around 1 million cycles) and batteries (around 10,000 cycles).

Flywheels can also extend the discharge time and the useful lifetime of batteries if combined together in a “hybrid” energy storage system.

Compact electro-mechanical battery

Flywheel energy storage is ideally suited to urban rail transportation because of the frequent number of stop-start cycles. A flywheel has high relative power density when compared with batteries, allowing it to rapidly capture the braking energy over a relatively short space of time without affecting the performance of the device.

The Williams flywheel system is relatively small and lightweight, helping with packaging integration. In addition, because the system is electro-mechanical, it can be located and packaged remotely from the driveline of the train.

Flywheels can also be operated at a much wider range of operating temperatures compared with other forms of energy storage.

Patented MLC technology

At the centre of the flywheel design is patented magnetically loaded composite (MLC) technology. This feature is unique to Williams’ flywheels and provides an inherently safe design – mitigating the safety concerns of conventional metallic or non-integrated carbon fibre flywheels. The MLC design reduces eddy current losses, thereby providing superior efficiency, thermal performance and deep cycling ability when compared with other flywheels.

A global leader in energy storage systems

Williams has become a global leader in energy storage systems following the introduction of Kinetic Energy Recovery Systems into F1 in 2009. Williams developed an innovative flywheel system for its F1 car and quickly realised the vast potential of this technology beyond the race track for improving energy efficiency in industrial applications.

Williams Advanced Engineering, the division of the Williams Group that commercialises F1 based technology, has further developed this technology for use in mass transit. The technology is currently being trialled in buses and trams with leading manufacturers such as Go-Ahead and Alstom, and successfully used in endurance racing with Porsche and Audi.