AQ Group, along with its subsidiary AQ Trafo, was founded in 1994 as a spin-out of ABB. AQ Group has vast experience in the railway industry and is one of the leading manufacturers of dry-insulated inductive components. Its product range also includes a broad spectrum of transformers and inductors.

Since AQ Group’s inception, a conscious emphasis on technical development, quality assurance and environmental adaptation has given AQ Group a leading position in the market and its products are used in some of the most demanding applications.

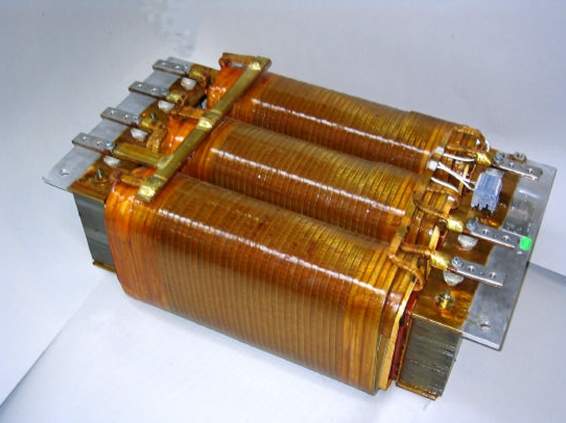

Transformers and inductors for rolling stock

Our transformers and inductors are used in many critical and demanding applications, such as main converters, auxiliary converters and electric cabinet assemblies. They are mounted on roofs, under trains, inside converter enclosures, in electric cabinets and on PCBs (printed circuit boards).

The products range from 1VA to 2MVA with a system voltage up to 3 kV. Our product range includes:

- HF inductors (25kHz)

- HF transformers (15kHz)

- DC line filter inductors with HF harmonics (typ. 3kHz)

- Three-phase filter inductors with HF harmonics (typ. 1.5kHz)

- Harmonics filters

- Mono and three-phase transformers

- Air coils

- Transformers with integrated inductor

- Natural air / forced air / water cooled

Global railway inductor and transformer production

We aim to serve our customers globally through our sales and development offices in Sweden, Italy, China and India. Our cost-effective production sites in Bulgaria, China and India are located in the regions where our customers have their businesses. Regional sales, development, support and production continues to be an objective for AQ Group.

IRIS certification and welding standards

AQ Group is committed to quality and reliability and we continuously adapt to new requirements in the railway market. Our factories in Bulgaria and China are IRIS-certified. They are also certified against EN ISO 15085-2 for welding of railway vehicle parts.

Customised development of inductive components

AQ Group specialises in customised products and offers a number of advanced services including feasibility studies, CAD design, FE electrical and mechanical analysis, and tests according to main EN/IEC standards.