Our offering covers a wide variety of component test benches at our facilities combined with a global on-track measurement deployment capacity, helping customers all over the world test rail products and systems.

From validation and verification testing in the development phase to product homologation and also failure detection / root cause analysis in the after-sales operation, at CETEST we can assist you during the full lifecycle of your product.

We are experts in instrumentation, measurement and control, providing testing according to international standards, as well as fully tailor-made solutions. Our test and instrumentation capacity is very diverse.

We want our clients to choose us as their internal test and evaluation department anytime and anywhere, as we operate as more than a contractor or a partner.

Our portable test rigs

CETEST offers a unique capacity in the railway sector with a series of portable test rigs that we can bring to our customers, helping them avoid the extra cost and effort of shipping large components or even full vehicles to an external laboratory.

Instead, CETEST brings the laboratory to you with full control of the test performance, minimising costs and risks. Our field testing deployment is global and very fast and our staff can perform testing in several continents simultaneously with full quality and best service.

Accredited laboratory

CETEST is an independent test centre, which is ISO 17025 accredited to perform testing according to European and other international standards. This means that all testing conducted under the framework of ISO 17025 correctly follows pertinent standards and therefore guarantees full compliance before national authorities. CETEST is also ISO 9001, ISO 14001 and EN 9712 accredited.

We also have recognition from, have worked with and been evaluated by safety authorities, notified bodies and independent experts from several countries, including Germany, France, Brazil, the UK, Belgium, Spain, India, Italy and the US.

Our clients

We provide services that cover homologation needs, design verification testing, research-related testing and after-sales testing support for passenger vehicle manufacturers, special track vehicle manufacturers, and component suppliers. We are also very active in the testing related to operations improvement for rail operators and infrastructure managers. Additionally, we work closely with other railway organisations, namely notified bodies, engineering firms and authorities.

Structural integrity and fatigue testing

Verification and validation structures from car bodies (EN 12663, APTA, etc), bogie frames (EN 13479, UIC 515-4 and UIC 615-4, etc) and bolsters to crash energy management systems, we carry out quasistatic and dynamic / fatigue testing, as well as non-destructive inspection. In this line, CETEST also performs on track testing for determining stress levels in different components.

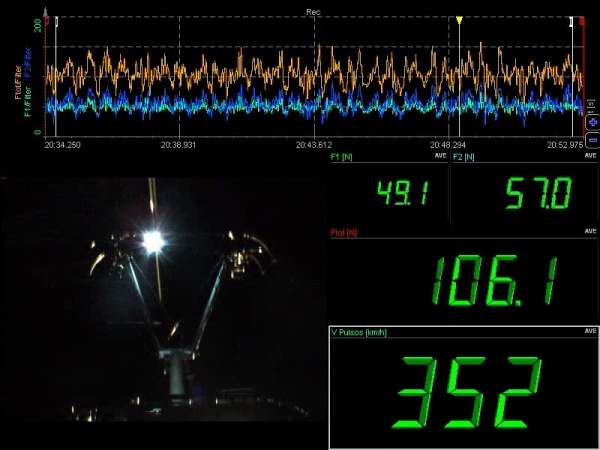

Instrumented wheelset

We provide our own proprietary patented advanced technology for instrumented wheelsets with an offering that goes from one-time test services for homologation to full turnkey systems. It is a sensing system capable of measuring, in an uncoupled manner, the contact forces associated to the wheel/rail interaction, offering unique performance and accuracy, thanks to calibration and verification made in both static and rolling conditions. The technology is tested in different vehicle types and at speeds that exceed 350km/h.

Dynamic behaviour testing

CETEST offers static suspension characterisation for full vehicles, including wheel equalisation, suspension flexibility, carbody / bogie rotational resistance, as well as vehicle centre of gravity determination.

CETEST also offers on-track dynamic testing for checking vehicle stability, safety against derailment, track fatigue and comfort characteristics. We measure vehicle dynamic behaviour from simple ride quality measurements to full complete rail / wheel interaction studies.

Noise and vibrations

CETEST can offer customers static and dynamics evaluation for all components, as well as for full vehicles, from single point vibration evaluation to complex multicomponent modal analysis and combined noise and vibration correlation studies.

Environmental tests

Climate testing can be carried out at a dedicated facility in Elmira, New York, US, as well as full test programmes on heating, air conditioning, air balance, thermal comfort and consumption. Several measurements can be made to verify heating and air conditioning performance and simplified climatic tests can also be carried out, including different heating and cooling cycles according to client needs.

At CETEST, we help our clients analyse aerodynamic phenomena related to train performance. Also, CETEST is a specialist in extensometric on-track tests.

CETEST carries out verification and validation of wheels, axles (EN 13260, EN 13261, EN 13262) and bearings (EN 12082), as well as functional testing of gearboxes and motors.

EMC and energy consumption

Electromagnetic compatibility related measurement is one of our core activities. We perform verification and validation of full vehicles, as well as components. Also, CETEST is accredited for the assessment and measurement of energy consumption in electric rail vehicles.

CETEST is accredited to carry out evaluation of traction and braking performance and current collection quality tests according to EN 50317, EN 50367 and TSI.