OKOndt Group has more than 30 years of experience in the manufacturing of non-destructive testing (NDT) rail inspection equipment.

Our rail flaw detectors inspect the railways of North America, Europe, Asia, Australia and Oceania. Along with traditional railway roads and underground rail systems (subways), special models of the flaw detectors allow for testing crane and tram rails.

Automated plants, portable flaw detectors and scanners manufactured by our group inspect the components of railway rolling stock, wheels, axles, and wheel pairs both at the time of their production and during operation, maintenance and repair.

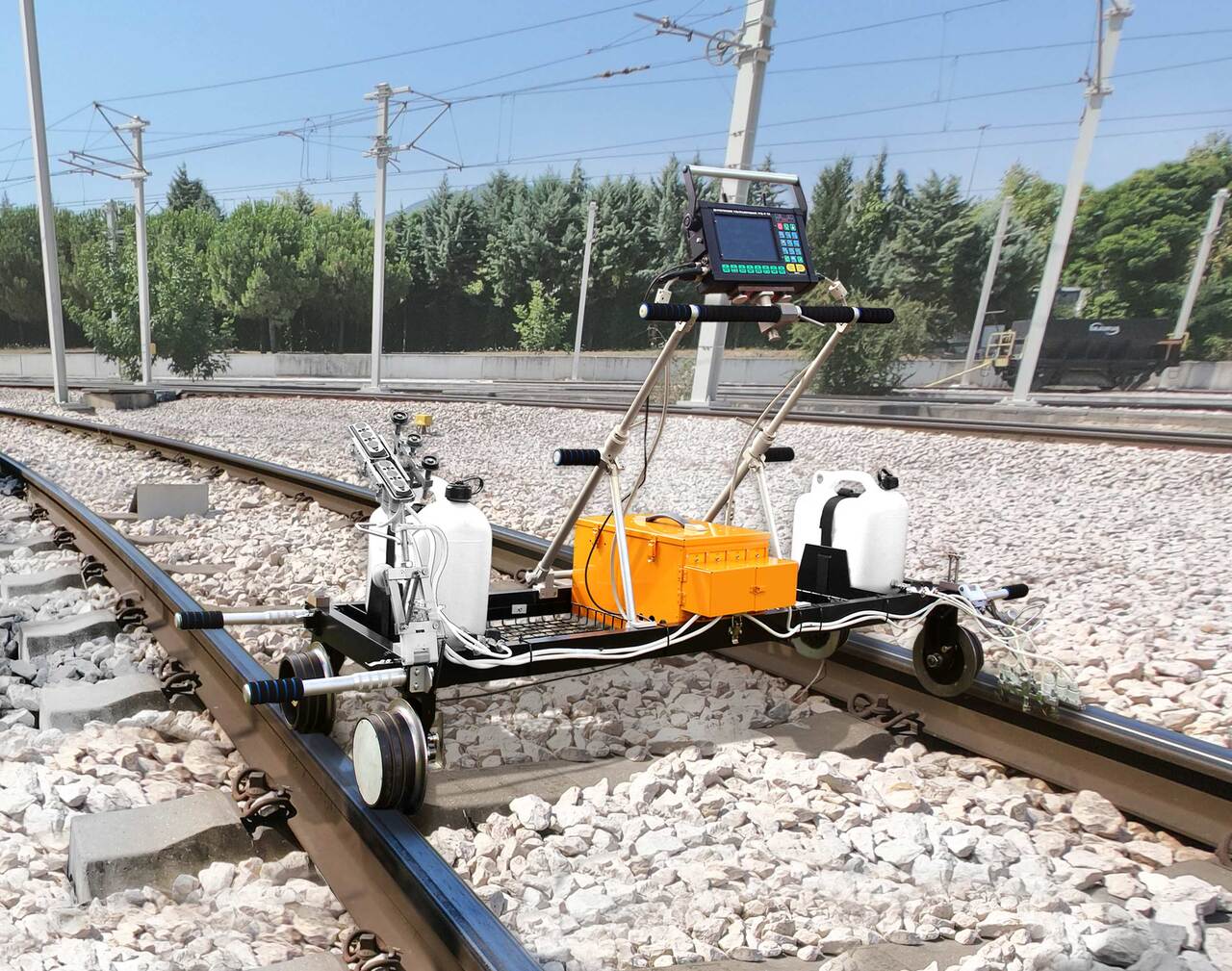

High-speed NDT rail testing equipment

For high-speed inspection of rails, OKOndt Group offers flaw detection trolleys of the OKOSCAN 73 HS series. This NDT equipment allows for continuous inspection of railway track at up to 40km/h (25mph) and is manufactured in several modifications, namely ultrasonic, eddy current and combined.

The combined model allows for detecting and recording of both the defects in the rail body itself and the running surface flaws of the rail head to assess the width of the layer subject to grinding.

As a manufacturer, OKOndt Group offers a solution for connecting the OKOSCAN 73 HS trolley (carriage) to any customer’s vehicle and testing of rails laid down in tracks with various track gauge width.

Confirmatory testing of railway rails

To confirm the results of high-speed inspection or of the rails testing on the road section (span) where high-speed inspection is not applicable, OKOndt Group offers several railway flaw detectors of various modifications.

Ultrasonic flaw detectors UDS2-77 (single-rail) and UDS2-73 (double-rail) allow for inspecting of the entire rail body at a speed between 4km/h and 5km/h, except for the rail base blades.

Eddy current flaw detectors ETS2-77 (single-rail) and ETS2-73 (double-rail) test the status of the rail head running surface and allow for not only fixing the running surface defects but also using a special algorithm to assess the flaw propagation depth, which is useful in determining the depth of railhead grinding.

Flaw detectors for testing tram, crane and other types of rails

For testing special-purpose rails, OKOndt Group offers specific models of the flaw detectors such as UDS2-77 CR for crane rails and UDS2-77 TRAM for status of the tram rails head. The company also recommends models for testing rails in subways and mining plants.

All the models are adapted to the parameters of the customer’s railway track, including track gauge width and rail geometry.

Portable flaw detectors for confirmatory testing of rails and welded rail joints

For detailed confirmatory rail testing and inspecting alumino-thermal rail joint conditions, OKOndt Group offers portable ultrasonic and eddy current instruments of the Sonocon B and Eddycon C series in various configurations with appropriate kits of transducers, calibration samples and special scanners (USR-01).

The instruments allow for manual detection and registration of the defects in accordance with the requirements of standards and regulatory documents.

Automated NDT rail inspection equipment

In addition to mobile NDT tools and instruments for railway tracks, OKOndt Group produces automated plants for manufacturing and service enterprises of railway transport.

Today, our plants inspect railway wheels, axles, wheel pairs, rail carriages underframes with ultrasonic, eddy current, magnetic particle and acoustic emission NDT techniques in several countries.

The combination of the variety of available solutions and the professionalism of OKOndt Group’s experts allow our partners finding the solution for the widest range of NDT tasks regarding railway tracks and railroad rolling stock.

Products manufactured by the OKOndt Group are supplied to 65 countries around the world.

Please fill out the enquiry form on this page to find out more information.