CM4 has proven experience with over 30 years in the design and turnkey construction of railway equipment, test benches, quality control equipment and special tools.

Railway engineering, tests and approvals, production and technical assistance

Using advanced technology, CM4 is responsible throughout all stages of the project, from the concept phase through to design, development, installation and maintenance. CM4 supports customers, providing local competences in engineering, tests and approvals, production and technical assistance.

Our team consists of highly qualified personnel in different fields of engineering, such as mechanical, welding, electrical, electronics, software, communications, industrial automation and processes.

Rolling stock application solutions

CM4 has the experience and the resources to develop any kind of solution related to the functionality of rolling stock applications at any stage of development, from the description of the technical specification of a component to the design and construction of test benches and required training.

CM4’s quality system meets transportation requirements and the key standards ISO 9001:2008 and EN 15085 CL4, and product assurance that is fully compliant to EN 50125, EN 50126, EN 50128, and EN 50155.

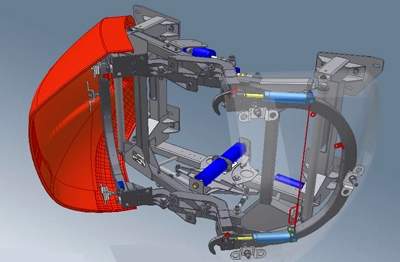

Front hatch mechanisms

Our mechanisms are suited to a wide range of requirements, customising the design to be installed in any type of front nose. CM4 offers the best quality and long product life with low maintenance and at a competitive price, giving advice and support to the client in its implementation on the train and performing all the necessary tests.

Our train-to-train infrared remote control is a tailor-made solution for any mechanism that communicates with both trains, enabling it to carry out the coupling manoeuvre automatically.

We have also designed and developed front nose projects in collaboration with composite parts manufacturers.

We have installed more than 2,500 front hatch mechanisms on trains during the last 15 years.

Mechanical devices

We offer total adaptation to the vehicle, whatever the stage of development of the customer’s project. Some examples include:

- Access ramps

- Detrainment doors

- Cabin access systems

- Front deflection systems for trams

- Cabin turnkey accessories and equipments

- Automatically articulated wing mirrors

- Cabin ergonomics systems

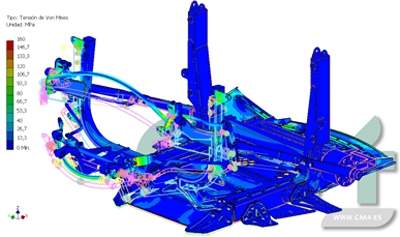

Design and construction of test benches and testing equipment

CM4 provides solutions to production and test departments, offering a complete service, designing and building from your needs for your product at any stage. We make it possible to control any parameter, either in the laboratory or on the production line.

We automate your processes through all kinds of production machinery, quality control and test benches, from initial development to construction and the final commissioning. Your products will offer the highest standards of quality by any test and control bench.

Some examples of design and construction include:

- Fixtures, jigs and benches for welding, assembly, quality control and automation

- Equipment for testing departments

- Gearbox test benches

- Levelling and weighing equipments for boxes on bogies

- Extensiometrics test benches

About CM4

CM4 began its activity in 1982. Throughout the years our team has maintained a steady growth, incorporating innovation in each of our products without losing the direct and personal relationship with all of our customers.

Rolling stock that has trusted us includes Alstom, CAF, Bombardier and Vossloh. Infrastructure managers and operators from organisations such as RENFE, SNCF, FGC, STIB, SBB and TMB have been involved in our projects and have even requested our services.